Pile foundation structure for reducing side friction force

A technology of side friction resistance and pile foundation, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems that hidden safety hazards cannot be discovered and eliminated in time, high operation and maintenance costs, and cannot be applied at the same time, so as to achieve good benefits, The effect of clear principle and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

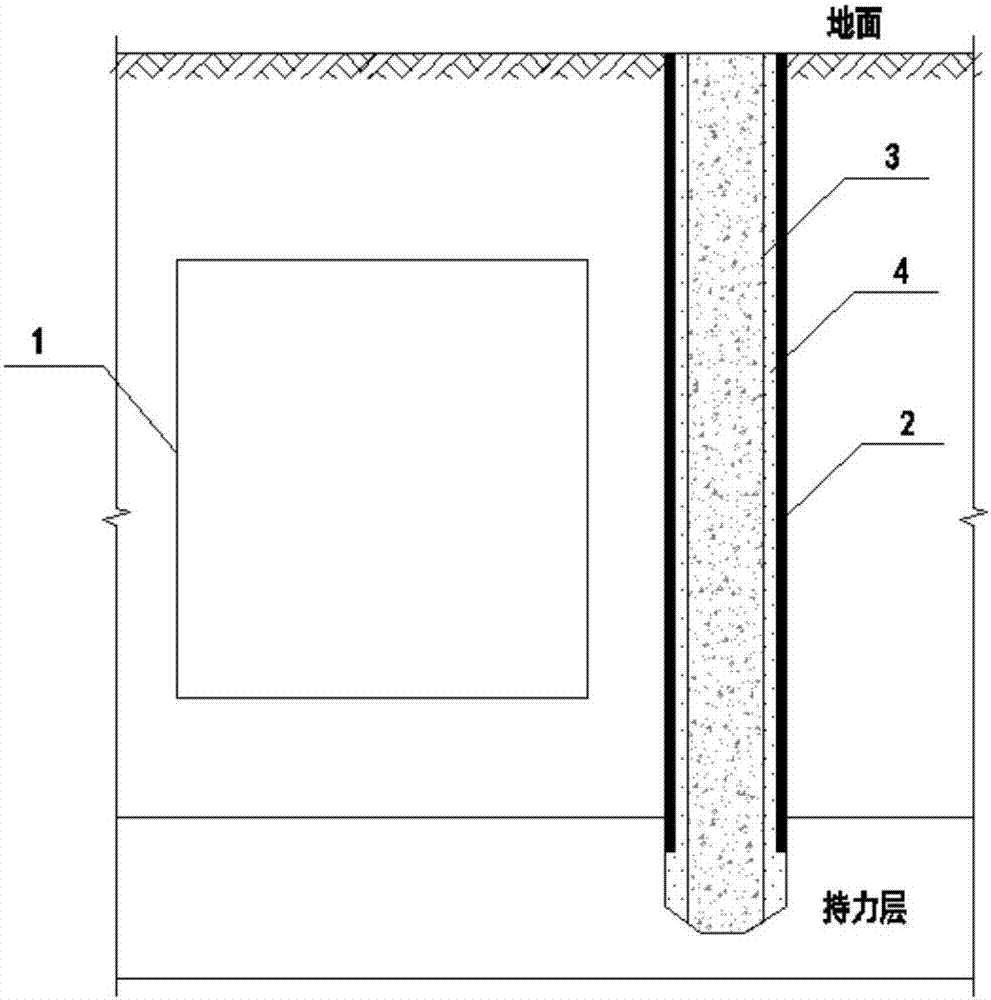

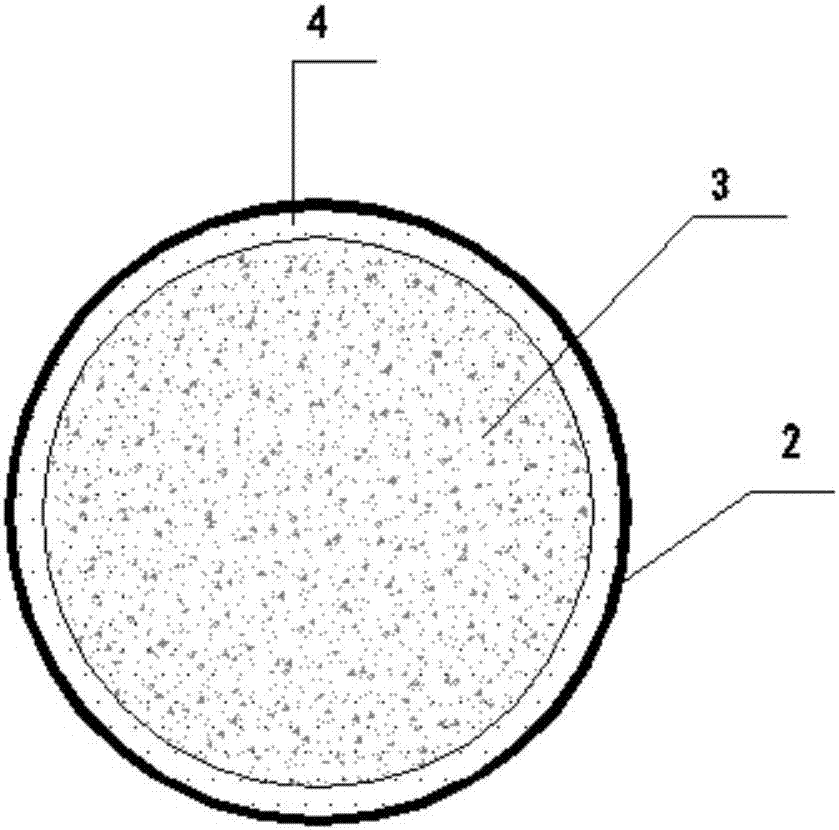

[0047] Such as figure 1 Shown, is a kind of pile foundation structure that reduces side frictional resistance, and it comprises pile body main body and outer sleeve 2, and lubricant 4, wherein,

[0048] The main body of the pile body adopts a preformed prefabricated pile 3, the top of the main body of the pile body is connected with the supporting platform, and the bottom of the main body of the pile body extends into the bearing layer to play a supporting role;

[0049] The outer sleeve 2 is sleeved on the periphery of the main body of the pile, and the soil layer on the side is separated from the main body of the pile, and the bottom ends of the outer sleeve 2 are extended into the bearing layer and fixed;

[0050] The gap between the main body of the pile body and the outer sleeve 2 is filled with a lubricant 4 for reducing the friction between the outer sleeve and the main body of the pile body,

[0051] The outer sleeve 2 and the prefabricated pile 3 are made of glass fi...

Embodiment 2

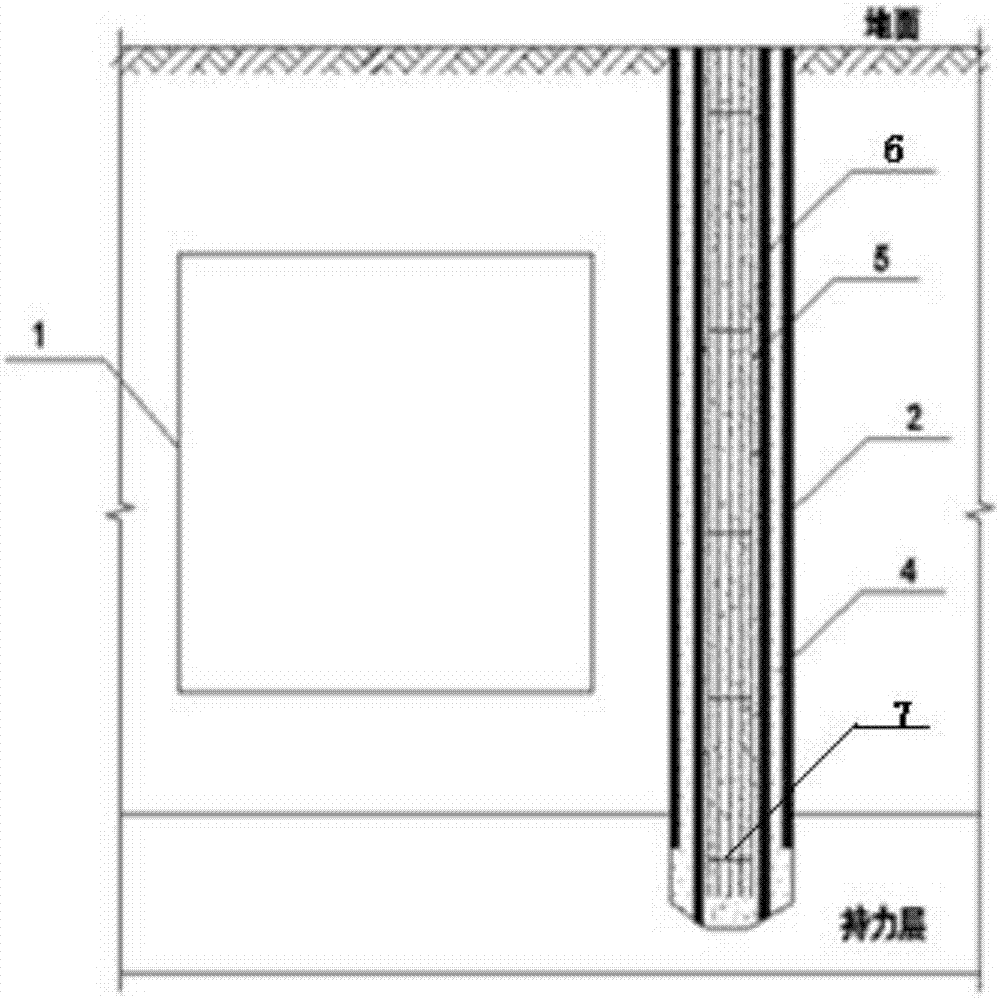

[0057] Such as figure 2 Shown, is a kind of pile foundation structure that reduces side frictional resistance, and it comprises pile body main body and outer sleeve 2, and lubricant 4, wherein,

[0058] The main body of the pile adopts a pile structure formed by on-site pouring, the top of the main body of the pile is connected to the supporting platform, and the bottom of the main body extends into the bearing layer to play a supporting role;

[0059] The outer sleeve 2 is sleeved on the periphery of the main body of the pile, and the soil layer on the side is separated from the main body of the pile, and the bottom ends of the outer sleeve 2 are extended into the bearing layer and fixed;

[0060] The gap between the main body of the pile body and the outer sleeve 2 is filled with a lubricant 4 for reducing the friction between the outer sleeve and the main body of the pile body,

[0061] The pile structure formed by pouring on site includes an inner sleeve 6 and poured con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com