Control method for engineering machinery hydraulic system

A technology of hydraulic system and control method, which is applied in the directions of fluid pressure actuation system components, fluid pressure actuation system testing, mechanical equipment, etc. The effect of saving system power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

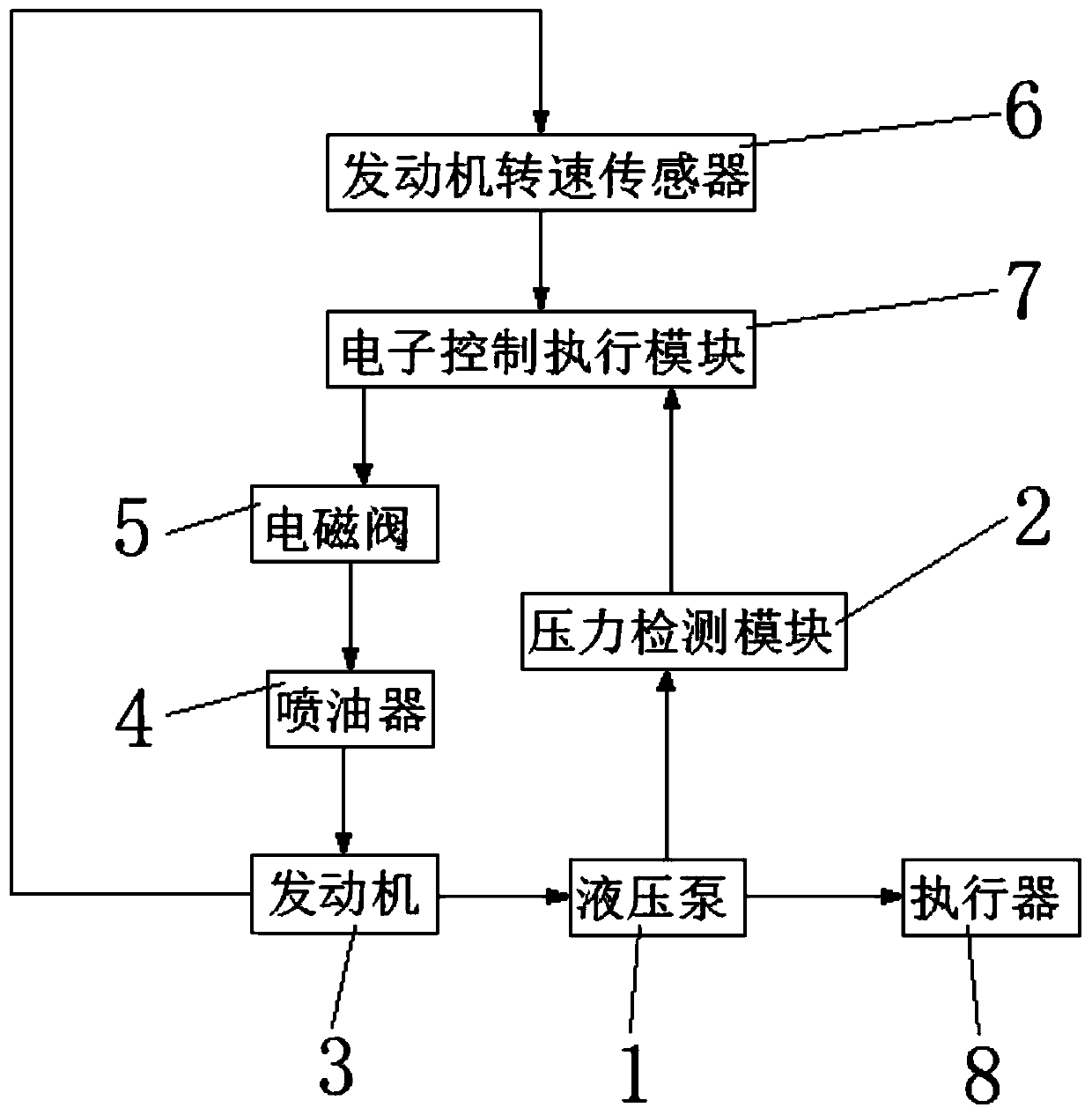

[0034] The present invention provides a control method for construction machinery hydraulic system, specifically as figure 1 As shown, the hydraulic system includes:

[0035] The hydraulic pump 1 is used to provide hydraulic oil for the hydraulic pipeline;

[0036] The pressure detection module 2 is used to detect the outlet pressure of the hydraulic pump 1. The pressure detection module 2 in this embodiment is a pressure sensor and is installed at the oil discharge port of the hydraulic pump 1;

[0037] The engine 3 is used to provide power for the hydraulic pump 1;

[0038] The fuel injector 4 is used to provide fuel for the engine 3;

[0039] The solenoid valve 5 is used to control the fuel injection quantity of the fuel injector 4;

[0040] The engine speed sensor 6 is used to detect the speed of the engine 3;

[0041] The electronic control execution module 7 is used to control the opening of the solenoid valve 5 according to the outlet pressure of the hydraulic pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com