Driving wheel

A driving wheel and driven gear technology, applied to the driving wheel. It can solve the problems of inconvenient installation of the driving gear and the passive gear, reduce the service life of the driving wheel, and unreasonable gear clearance, and achieve the effect of ingenious structure, elimination of machining errors, and uniform and stable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

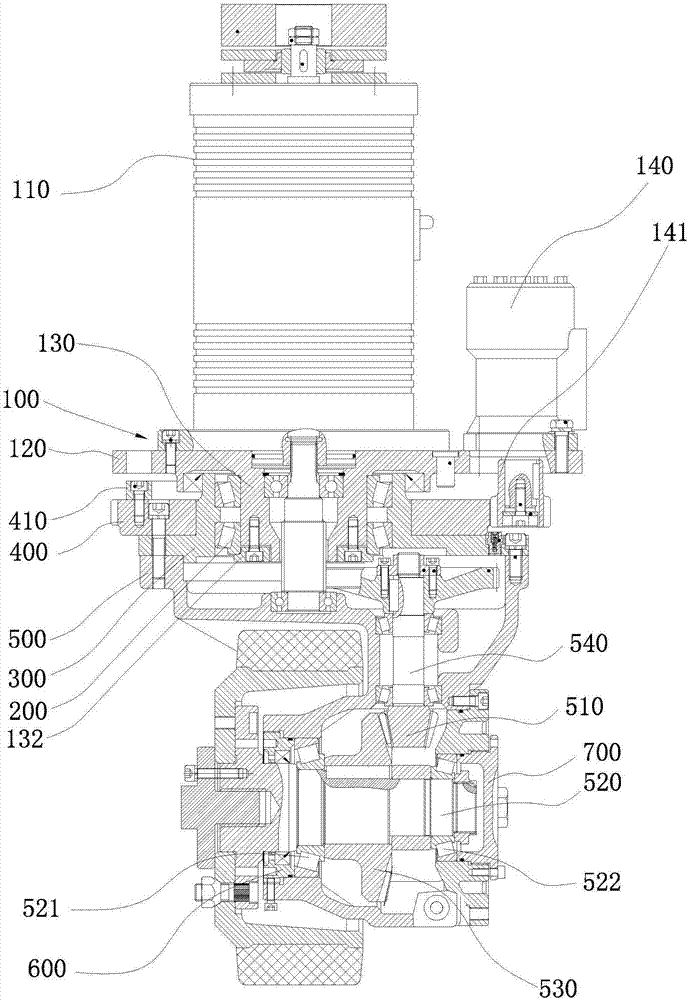

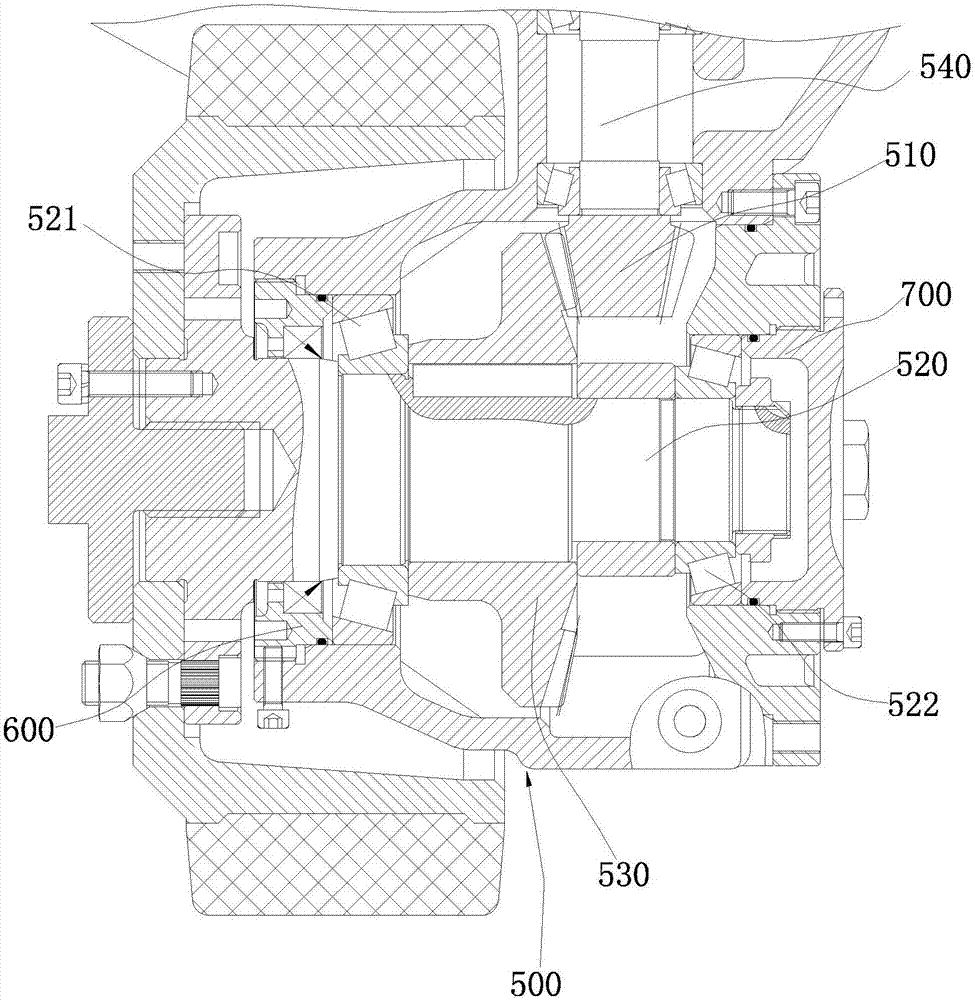

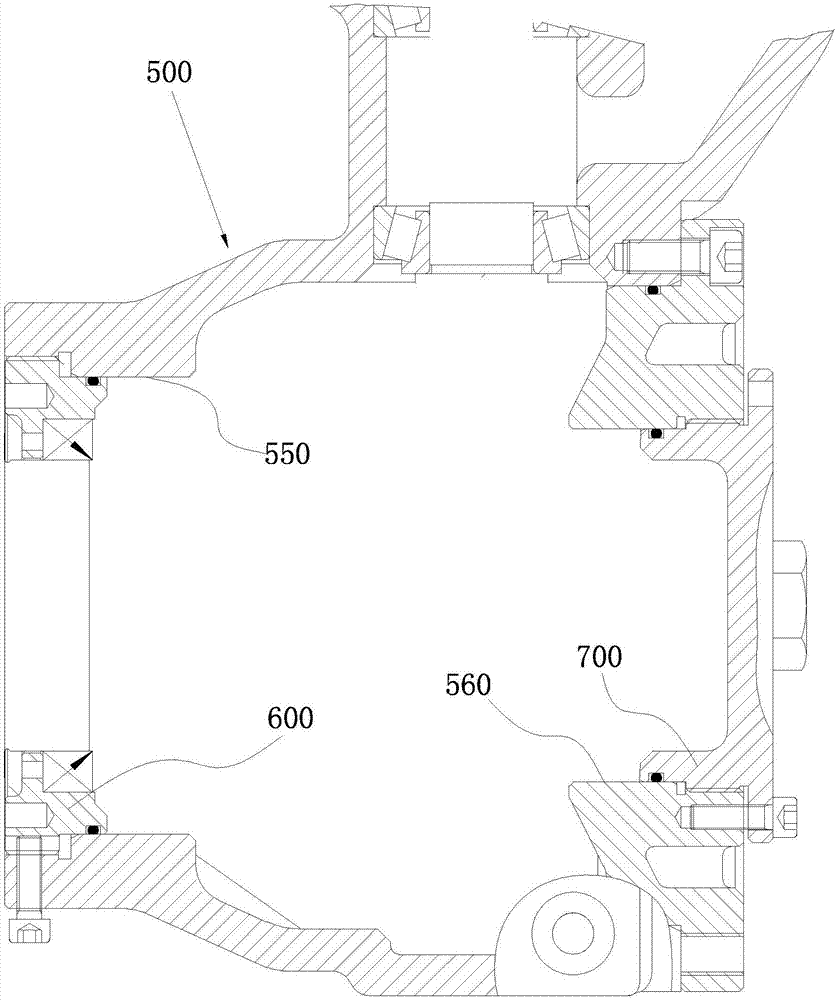

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a driving wheel is preferably applied to electric vehicles, especially electric forklifts.

[0037] The driving wheel includes: a driving wheel mounting base 100, a connecting bearing 200, a bearing housing 300, a steering ring gear 400, a gear box 500, a driven gear 530 and a first adjustment module.

[0038] Its working principle is: the gap between the driving gear 510 and the driven gear 530 can be adjusted, and the adjustment steps are less, the operation is relatively simple, and the adjustment accuracy is also high; it can also drive the steering ring gear 400, so that the The bearing seat 300 rotates, and there is a connecting bearing 200 betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com