Automatic gear shift control system and method for electric fork-lift truck

An automatic shifting and control system technology, which is applied in the direction of transmission device control, lifting device, and components with teeth, etc., can solve the problems of electric forklift driver's complicated operation, affecting the operating efficiency of the motor, and not being able to automatically switch, etc., to achieve relief Effects of weight, improved drivability, and power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

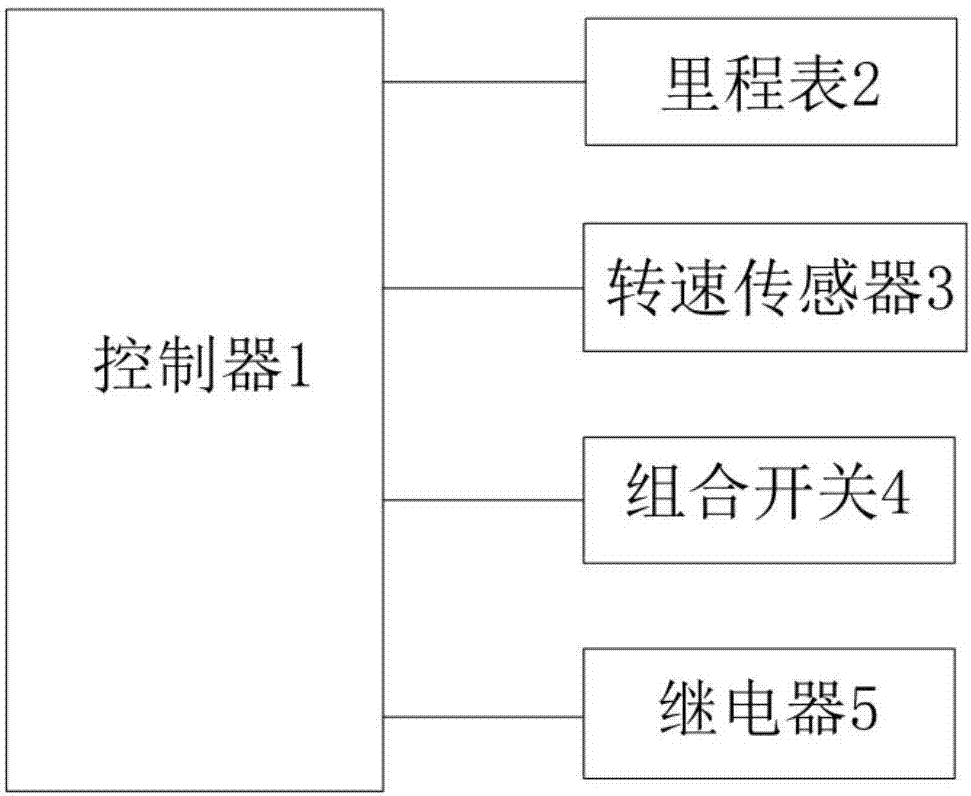

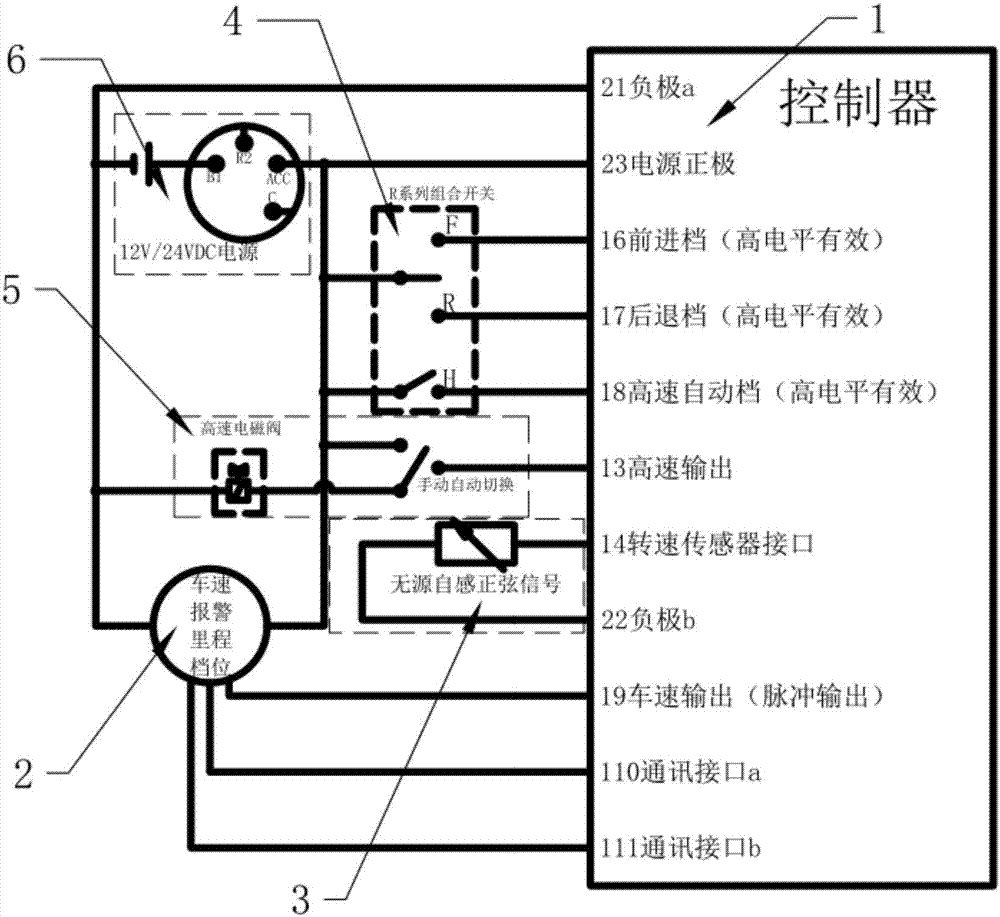

[0023] Such as figure 1 , 2 , 3, the electric forklift automatic shift control system includes a controller 1, an odometer 2, a speed sensor 3, a combination switch 4, a relay 5 and a power supply 6, and the controller 1 includes a forward gear 16, a reverse gear 17, High-speed automatic gear 18, high-speed output 13, speed sensor interface 14, vehicle speed output 19, communication interface a110, communication interface b111, negative pole a21, negative pole b22 and power supply positive pole 23; forward gear 16, reverse gear 17, high-speed automatic gear of controller 1 The gear 18 is electrically connected to the F port, the R port and the H port of the combination switch 4 respectively, the power input terminal of the combination switch 4 is connected to the positive pole of the power supply 6, one positive pole interface of the relay 5 is electrically connected to the high-speed output 13, and the other positive pole interface is connected to the power supply 6 direct c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap