Electric power engineering pipeline connection construction method and fuse machine for construction

A technology for electric power engineering and electric power pipelines, which is applied in the field of electric power engineering pipeline connection construction methods and construction hot-melting machines, can solve the problems of easy lifting of the ends of electric power pipelines, difficulty in centering operations, and unfavorable construction efficiency, and avoids the need for The effect of inaccurate docking, avoiding uneven force, reducing counterweight and purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

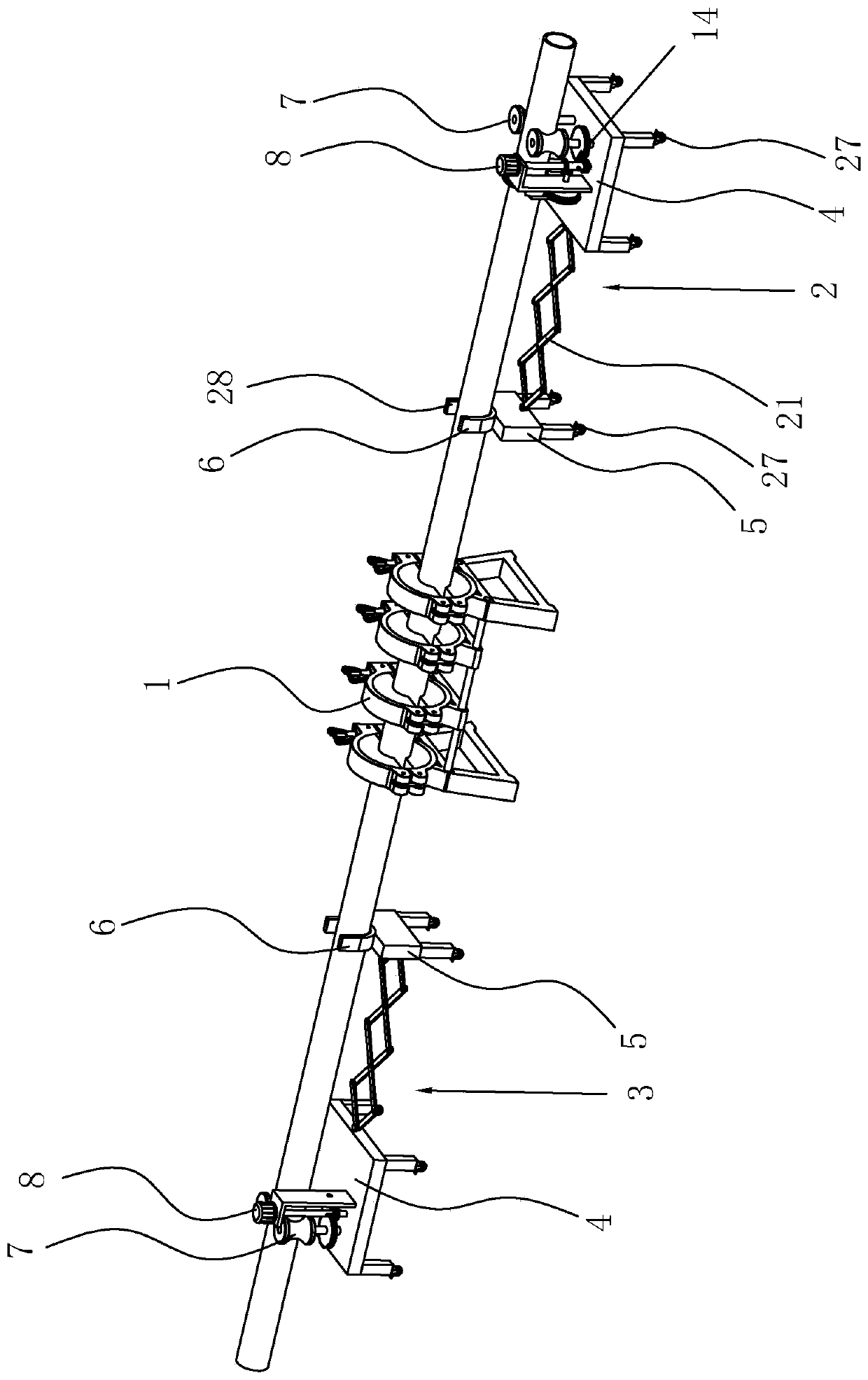

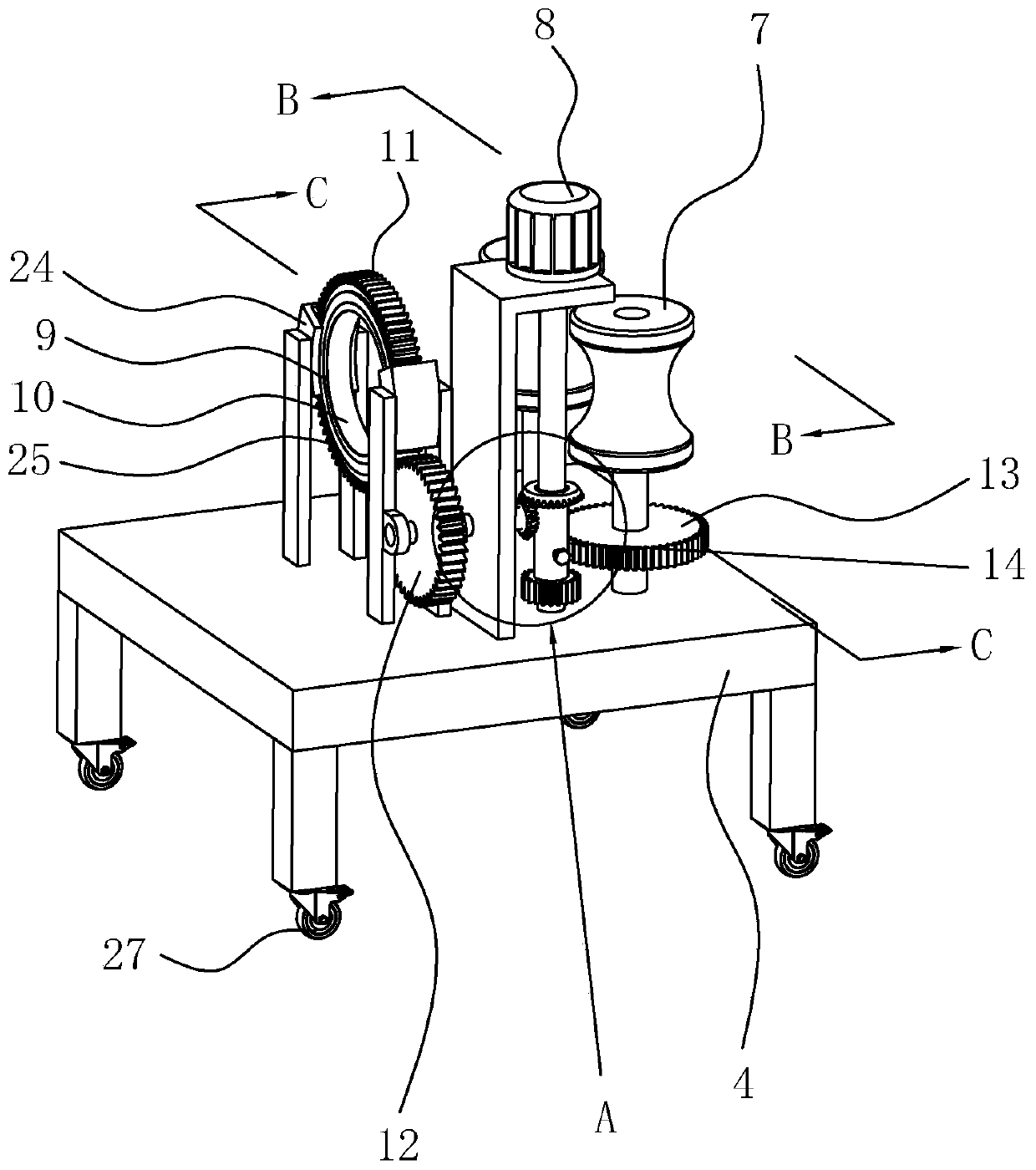

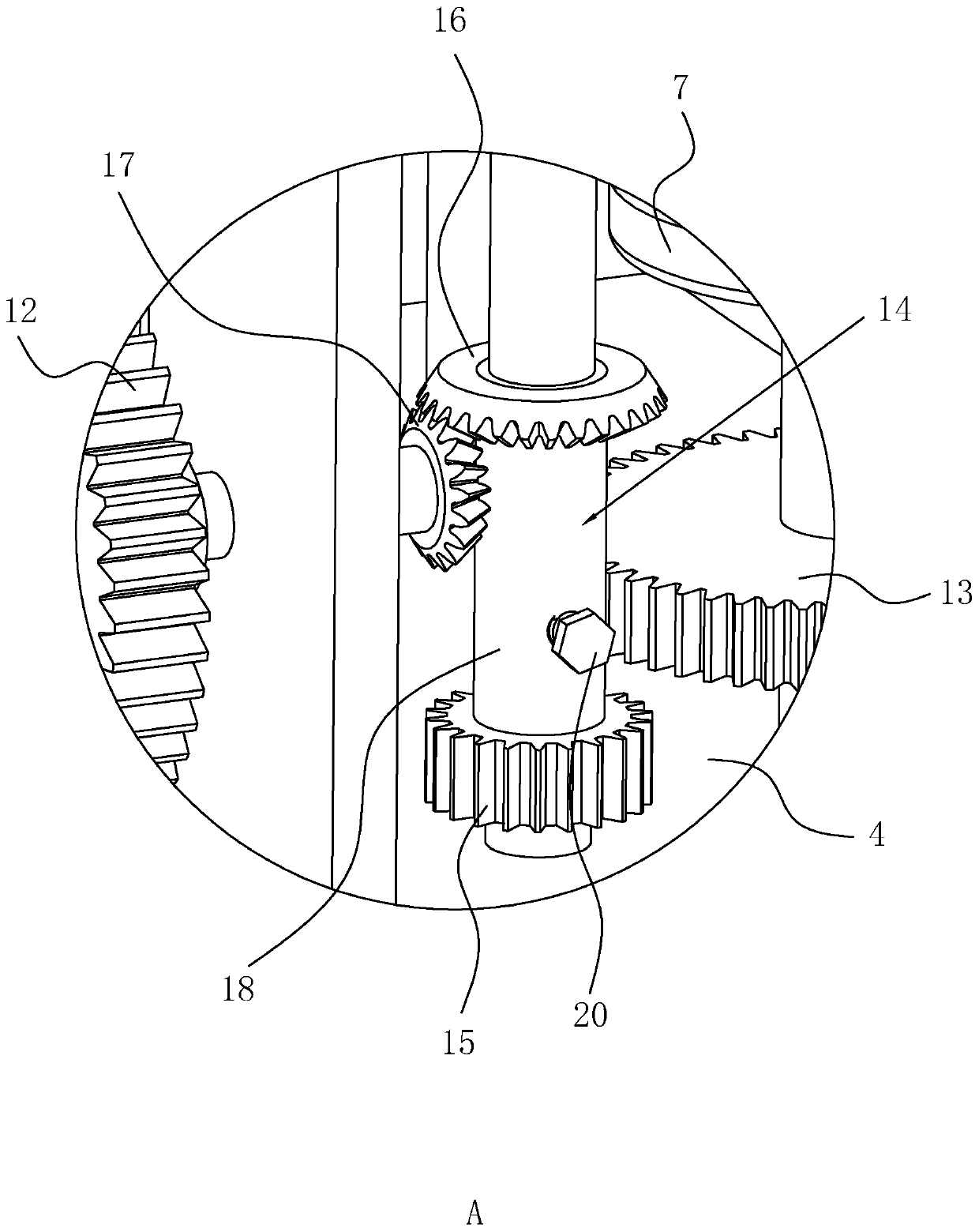

[0048] refer to figure 1 and figure 2 , is a hot-melt machine for power engineering pipeline connection construction disclosed by the present invention, comprising a hot-melt machine body 1 and a main supporting device 2 and a secondary supporting device 3 respectively arranged on both sides of the hot-melting machine body 1, the main supporting device Both the supporting device 2 and the auxiliary supporting device 3 include a main base 4 and an auxiliary base 5 arranged adjacent to the body 1 of the hot-melt machine. A bracket 6 is fixedly connected to the auxiliary base 5. The bracket 6 is in the shape of a "U" and the inner side of the upper end The wall is fixed with a rubber layer 28; the main base 4 is provided with a feed mechanism for driving the power pipeline along the direction of the arrangement of the main base 4 and the auxiliary base 5, and the feed mechanism includes two rollers that are rotatably connected to the main base 4 7. The power pipeline points to ...

Embodiment 2

[0058] refer to Figure 6 , is a kind of power engineering pipeline connection construction method disclosed by the present invention, adopts the hot-melt machine for power engineering pipeline connection construction as described in embodiment 1, comprises the following steps:

[0059] S1. Pipeline preparation: Support the two power pipelines to be connected through the main supporting device 2 and the auxiliary supporting device 3 respectively, and ensure that the two power pipelines are straight and coaxial, and clean the connection ends of the two power pipelines ;

[0060] S2. Cutting: Cut the impurities and oxide layers at the butt ends of the two power pipes, and ensure that the two butt ends are flat and smooth;

[0061] S3. Centering: Inflate the annular airbag through the air source to fix the short power pipe on the clamping ring 9, move the sliding sleeve 18 to make the main bevel gear 16 mesh with the auxiliary bevel gear 17, and then rotate the bolt 20 to The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com