Vertical boiler exhaust noise elimination device

A sound-absorbing device and vertical boiler technology, which is applied to steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems that the sound-absorbing effect is difficult to meet the noise standard, and the emission frequency bandwidth is good, so as to achieve good sound-absorbing effect, The effect of large noise reduction and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

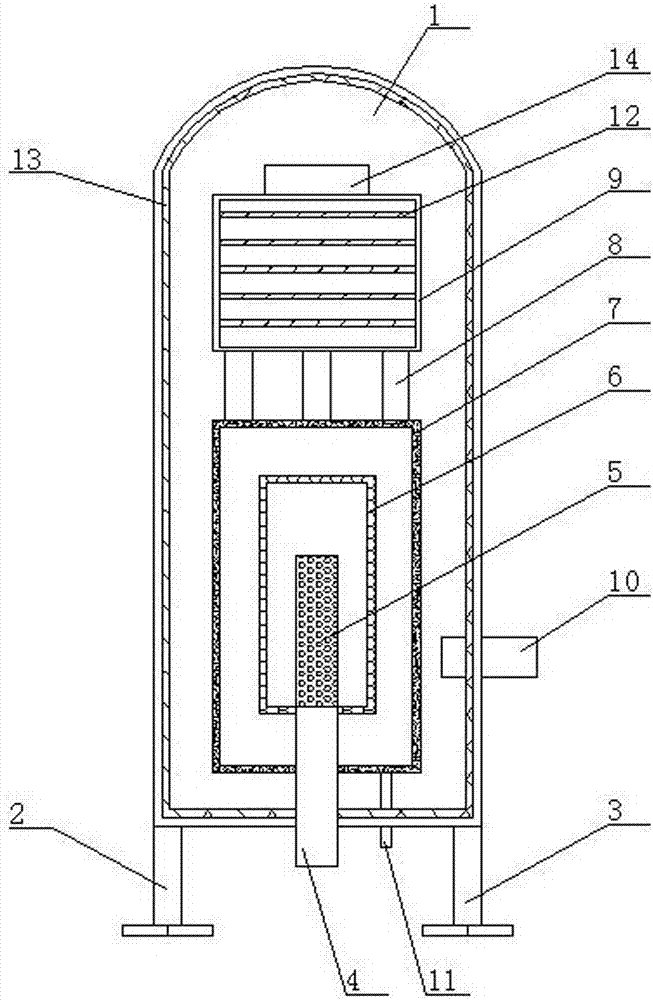

[0017] Such as figure 1 As shown, a vertical boiler exhaust silencing device includes a silencing cylinder 1, a left supporting leg 2, a right supporting leg 3, an air intake pipe 4, a silencing pipe 5, an inner silencing chamber 6, an outer silencing chamber 7, a ventilation pipe 8, Sound resistance chamber 9, exhaust pipe 10, the bottom end of the silencer tube 1 is supported by the left support leg 2 and the right support leg 3; the bottom end of the silencer tube 1 is equipped with an air intake pipe 4, and the air intake pipe 4 is connected to the silencer tube 1. Internal muffler pipe 5. The muffler pipe 5 is installed inside the inner muffler chamber 6. The inner muffler chamber 6 shown is installed inside the outer muffler chamber 7. The outer muffler chamber 7 is installed at the lower end of the muffler cylinder 1. The muffler cylinder 1. The upper end of the interior is equipped with a sound-resistance chamber 9, and the top of the outer anechoic chamber 7 is con...

Embodiment 2

[0019] Such as figure 1 As shown, the muffler pipe 5 is a straight pipe with a plurality of circular through holes arranged on the pipe surface.

Embodiment 3

[0021] Such as figure 1 As shown, a plurality of elliptical hollow holes are installed on the wall of the inner muffler chamber 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com