Domestic garbage incineration equipment

A technology for domestic waste incineration and equipment, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve problems such as high water content, difficult combustion, and complex composition of domestic waste, and achieve guaranteed combustion effect, energy saving, and energy saving. human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. What is described here is only used to illustrate and explain the present invention, and is not intended to limit the present invention.

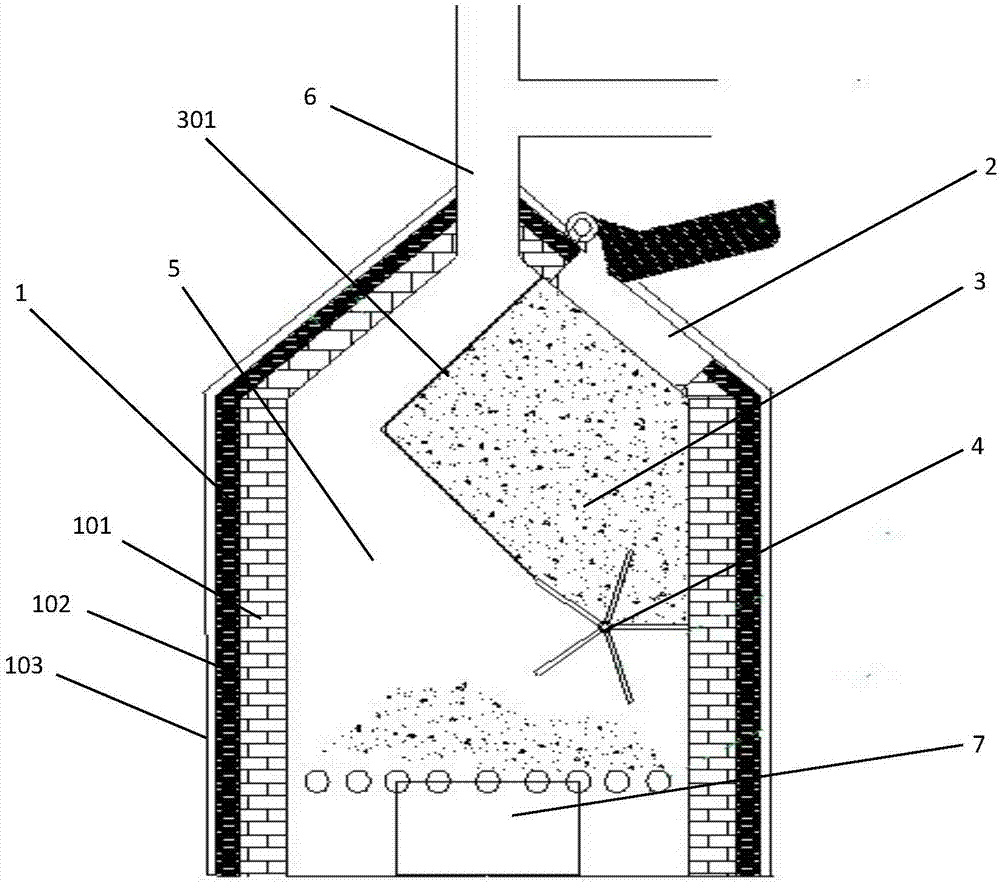

[0020] Such as figure 1 As shown, the present invention is a domestic waste incineration equipment, comprising a furnace body 1, a feed port 2, a drying chamber 3, a feeding drum 4, a combustion chamber 5, a smoke exhaust port 6 and a slag removal port 7, the furnace body 1 is divided into three layers, the innermost is the refractory layer 101, the middle is the heat insulation layer 102, and the outermost is the appearance layer 103. The combustion chamber 5 is located in the furnace body 1, and the drying chamber 3 is located in the furnace body 1. Above, the feed inlet 2 is located on the upper part of the entire combustion equipment, which is convenient for feeding. When feeding, the feed inlet is fully opened, and the garbage is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com