Flue gas purification system

A flue gas purification system and flue gas emission technology, applied in the field of flue gas purification, can solve the problems of increased equipment cost investment, complex structure of the flue gas purification system, increased operating costs and energy consumption of the flue gas purification system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

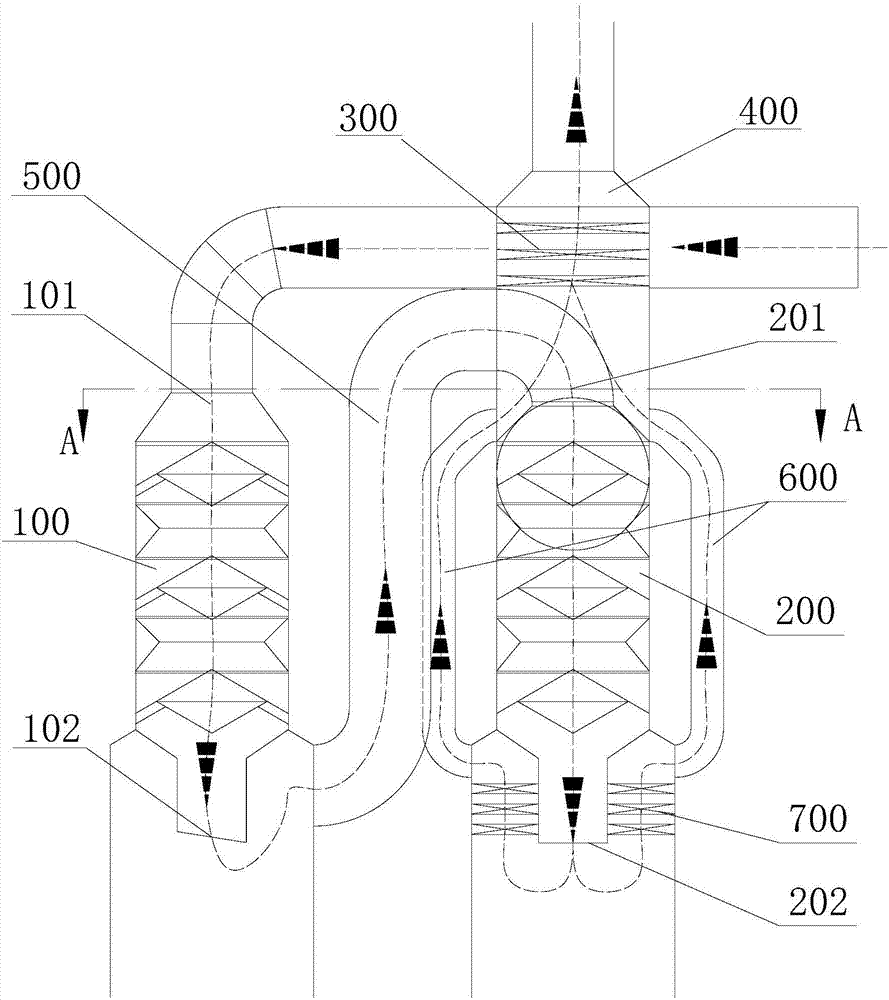

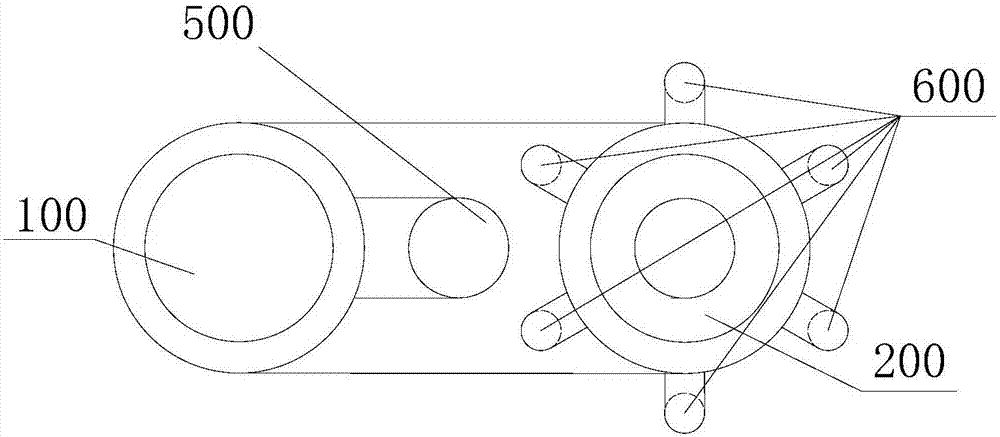

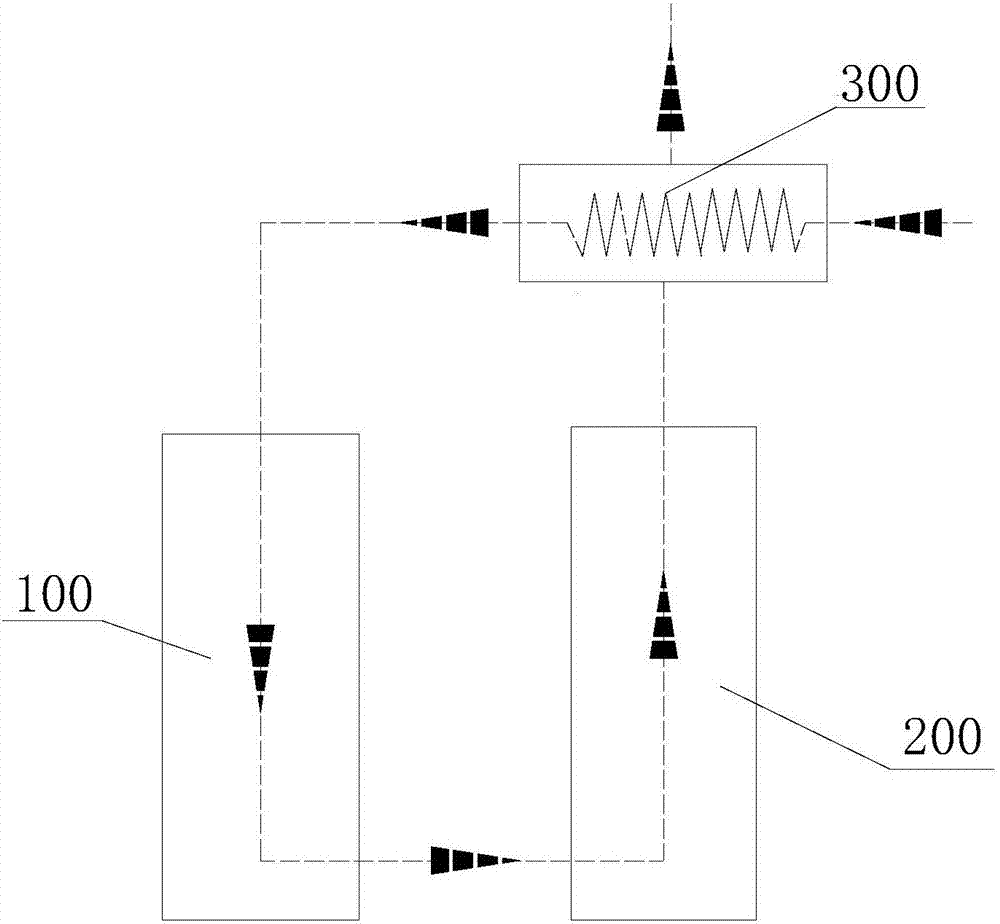

[0020] In the known technology, the temperature of the flue gas to be purified discharged from the flue gas production equipment is relatively high. Before the flue gas to be purified (high temperature flue gas) enters the flue gas purification system, it is necessary to set up a corresponding cooler to cool the flue gas to be purified to avoid The temperature in the reactor is too high. In view of the shortcomings of the background technology, one of the cores of the present invention is that the heat energy in the high-temperature flue gas is transferred to the purified flue gas (low-temperature flue gas), so as to achieve the purpose of heating the low-temperature flue gas and at the same time achieve the effect of reducing the high-temperature flue gas . The specific implementation of the flue gas purification system provided by the present invention is described below. The flue gas purification system can be used for desulfurization and / or denitration or removal of other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com