Novel magnetic Hall liquid level sensor

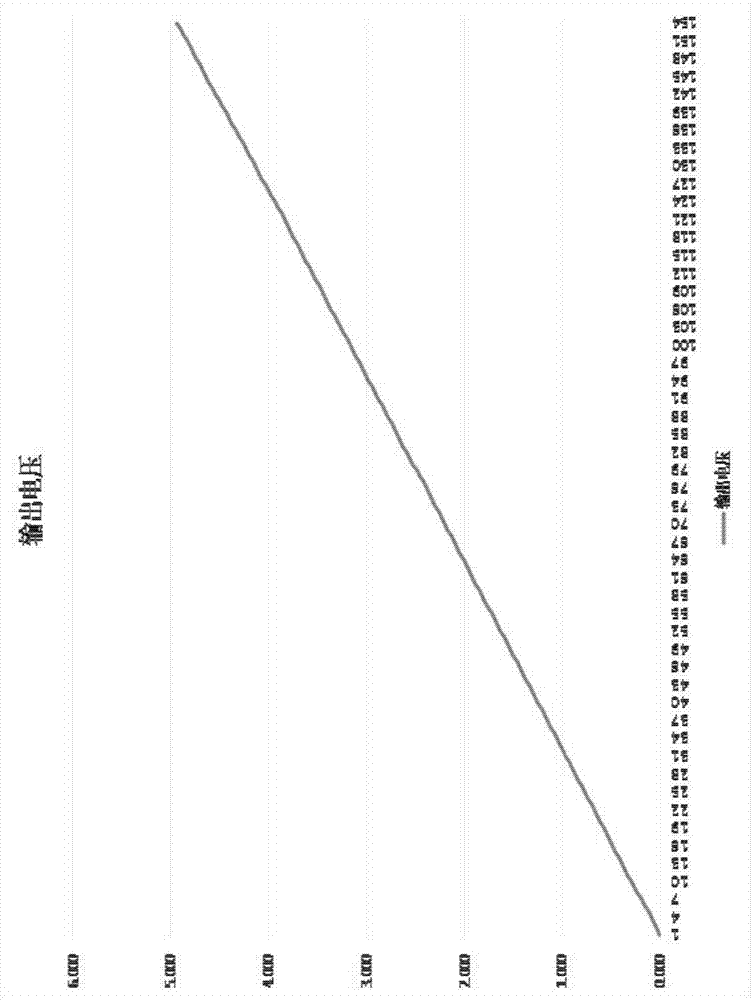

A technology of liquid level sensor and magnetic Hall, applied in the direction of buoy liquid level indicator, etc., can solve the problems of low resolution, high versatility, high production cost, etc., and achieve improved data sorting efficiency, high resolution, easy Effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings.

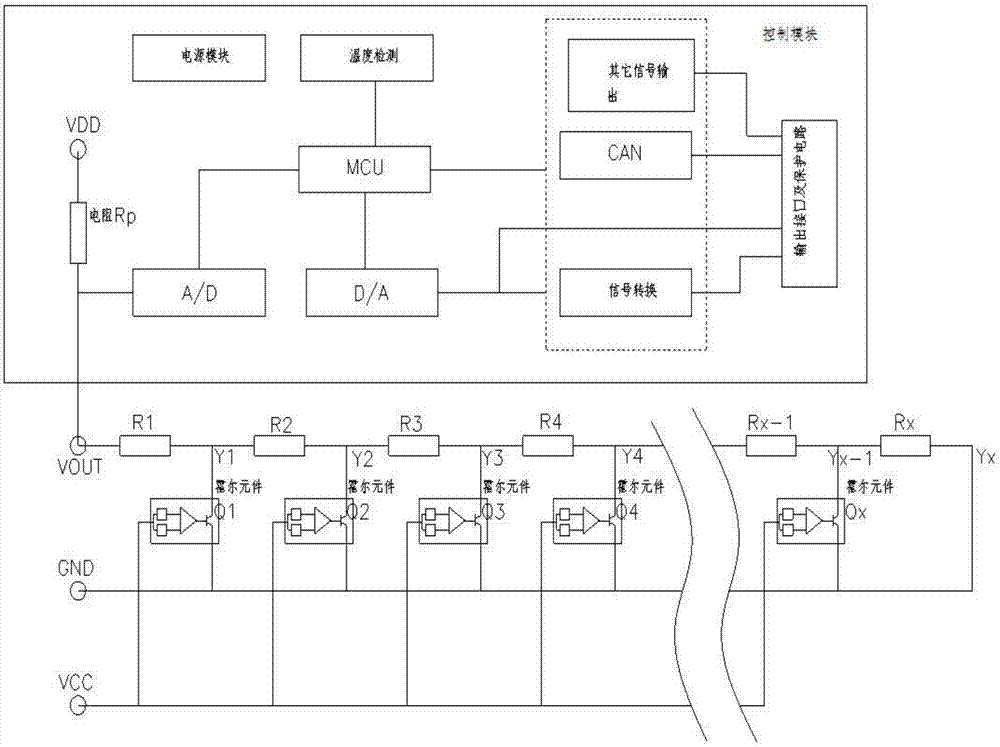

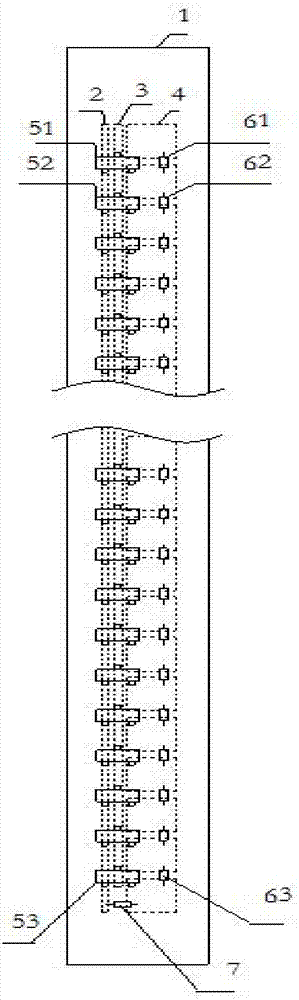

[0024] A new type of magnetic Hall liquid level sensor, including a housing and a PCB board 1 arranged in the housing and matched with the housing, the housing shell is provided with a float, and the float is provided with a magnet for generating a magnetic field. It also includes a control module, the control module includes an MCU controller for receiving and processing the collected data signals and sending out instruction signals, an A / D conversion module for converting analog signals into digital signals, and an A / D conversion module for converting digital signals It is a D / A conversion module for analog signals, a temperature detection module for detecting temperature, and a signal output interface module for outputting liquid level data signals obtained after MCU processing. The A / D conversion module, D / A conversion Module, temperature detection module and sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com