Glass cover plate and manufacturing method thereof and optical fingerprint sensor

A fingerprint sensor, glass cover technology, applied in optics, optical components, acquisition/organization of fingerprints/palmprints, etc., can solve the problems of complex structure, high cost, shorten the service life of mobile terminals, etc., to improve the penetration, Energy damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

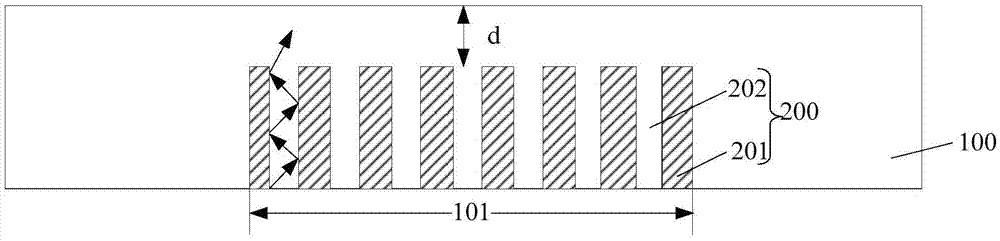

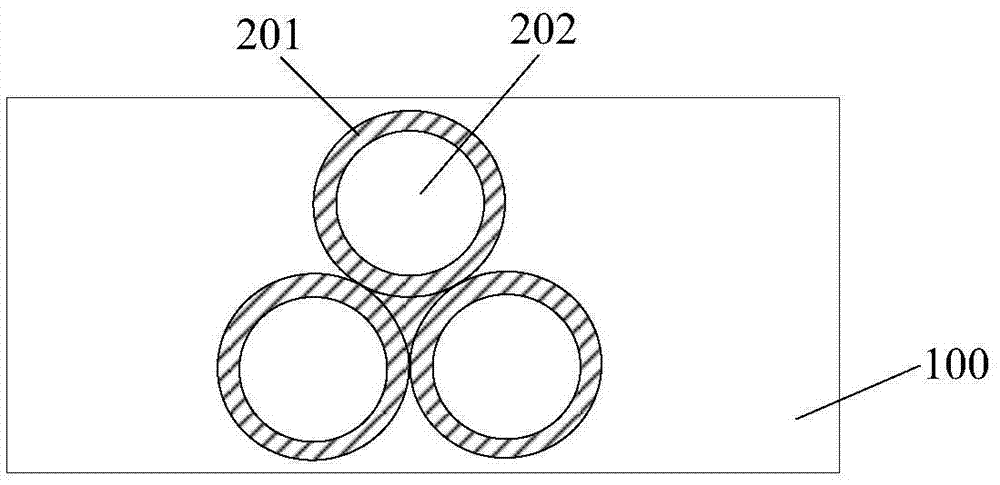

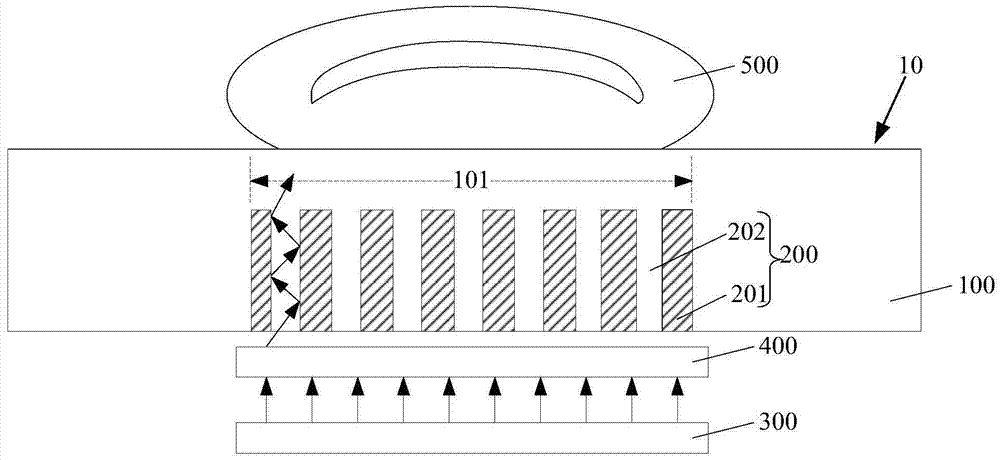

[0038] As mentioned in the background technology, due to the large thickness of the existing glass cover and the large energy loss of light propagation, the fingerprint identification module cannot be directly installed under the glass cover, and the use of a hole-digging structure will affect the mechanical strength of the glass cover. And the process is complicated and the cost is higher.

[0039] A modified area is formed on the glass cover plate of the embodiment of the present invention, and there is a total reflection path of light in the modified area, thereby improving the transmission performance of light without affecting the mechanical strength of the glass cover plate, and can be installed directly under the glass cover plate The fingerprint module has simple process and low cost.

[0040] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com