Laser cleaning device

A laser cleaning and cleaning technology, applied in the field of laser applications, can solve the problems of low cleaning efficiency, limited cleaning efficiency, low laser power, etc., and achieve high cleaning efficiency, fast and efficient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

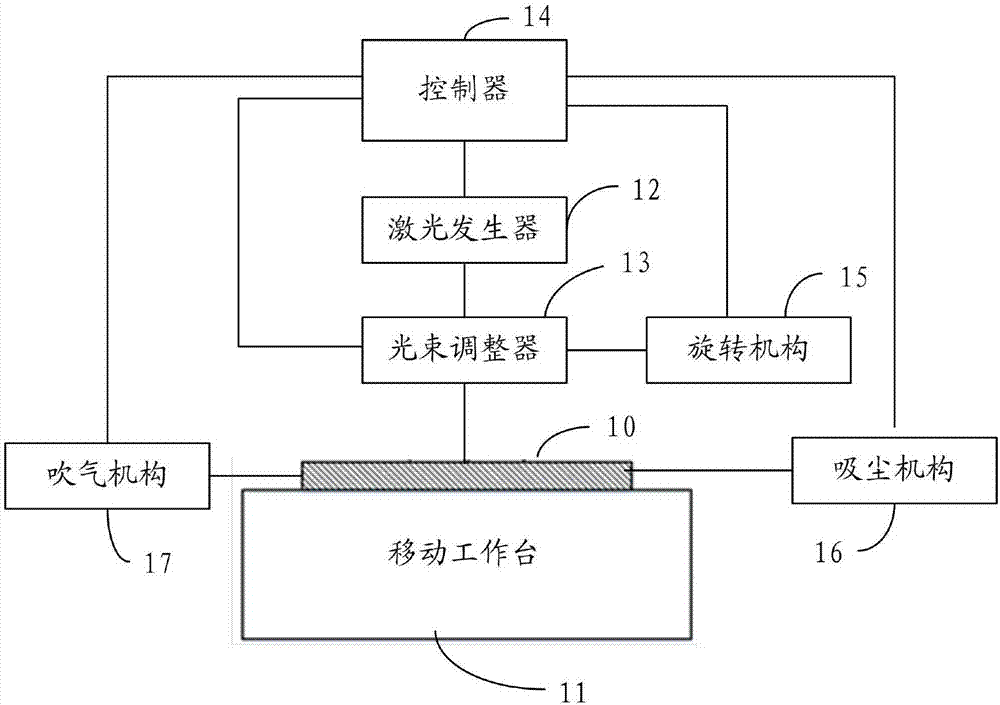

[0046] Such as figure 1 As shown, the laser cleaning device for cleaning the object 10 to be cleaned includes: a mobile workbench 11, a laser generator 12, a beam adjuster 13, a controller 14, a rotating mechanism 15, a dust suction mechanism 16 and an air blowing mechanism 17, wherein ,

[0047] The mobile workbench 11 is used to place the parts to be cleaned 10, and when the mobile workbench 11 moves, the parts to be cleaned 10 are driven to move horizontally;

[0048] The laser generator 12 is arranged corresponding to the mobile workbench 11 for emitting laser light;

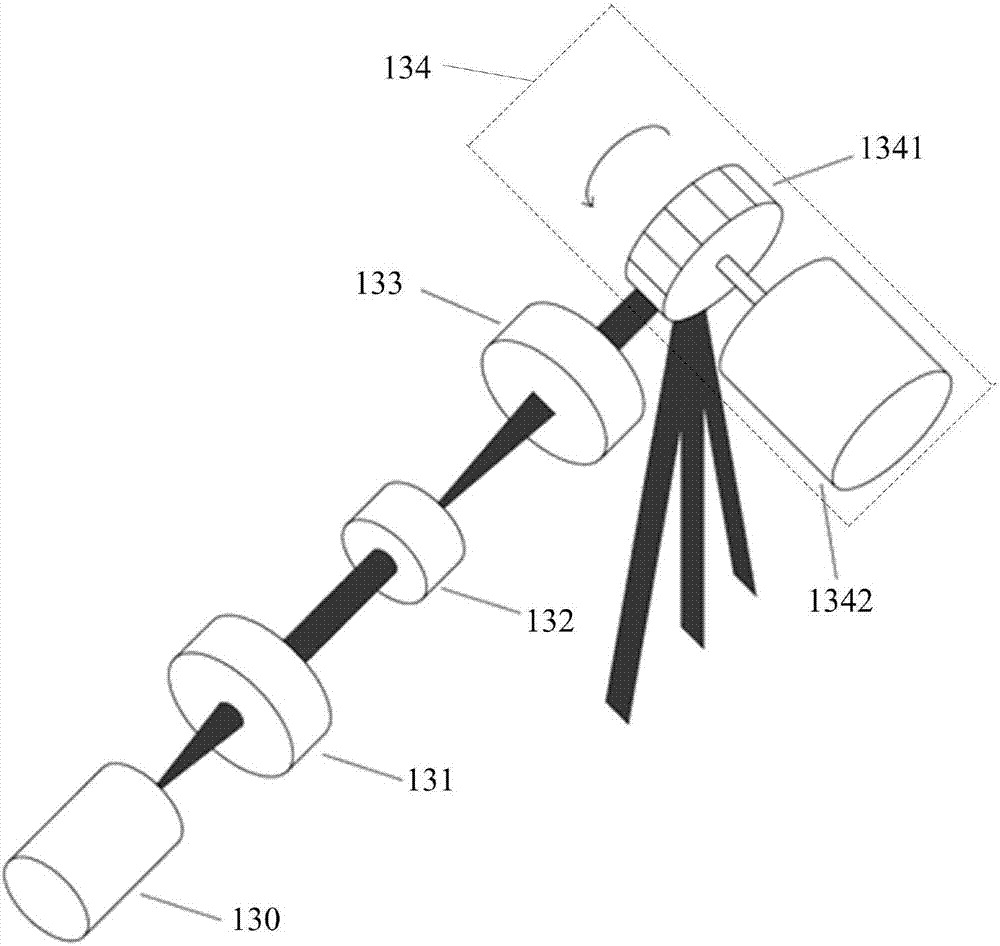

[0049] The beam adjuster 13 is arranged corresponding to the laser generator 12, and is used to adjust the laser beam into a strip shape and scan the scanning laser beam of the object to be cleaned 10 at a set scanning speed;

[0050] The controller 14 is connected with the mobile worktable 11, the laser generator 12 and the beam adjuster 13 respectively, and is used to set the laser power of the laser gen...

Embodiment 2

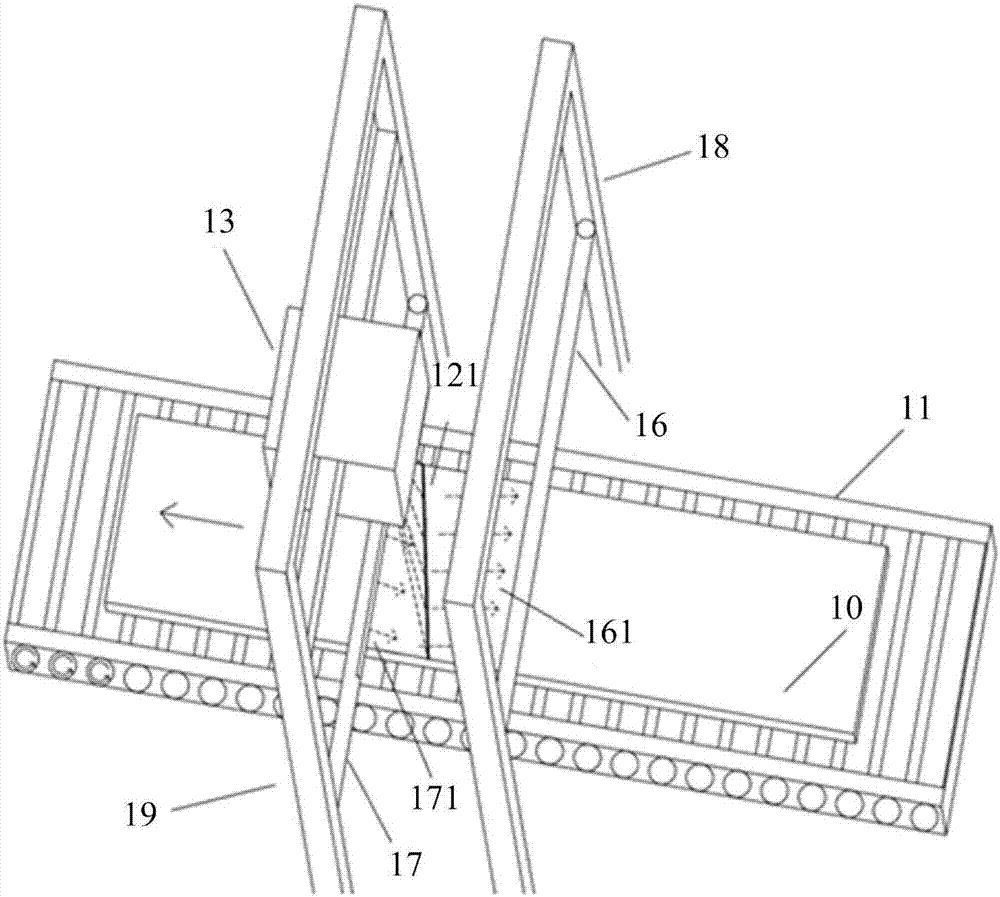

[0071] Such as image 3 and Figure 4 As shown, the laser cleaning device includes: a controller 14 , a laser generator 12 , a beam adjuster 13 , an air blowing mechanism 17 , a dust suction mechanism 16 , and a moving work 11 and a rotating mechanism 15 . The controller 14 can control the laser generator 12 and the beam adjuster 13, so that the laser generator 12 emits a laser beam 121 with set process parameters, and transmits the laser beam 121 to the beam adjuster 13 through an optical fiber for beam shaping. At the same time, the controller 14 can also control the movement of the movable worktable 11, cooperate with the auxiliary function of the air blowing mechanism 17 and the dust suction mechanism 16 to clean the surface of the workpiece 10 to be cleaned evenly and efficiently, thereby removing the oxide film on the surface of the workpiece. In this embodiment, the mobile workbench 11 is a roller workbench; the controller 14 includes an input and output device 141 , a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com