A multi-liquid cylinder type pit heat transfer tube extrusion molding device

A technology for extrusion molding and heat transfer tubes, which is used in molding tools, heat exchange equipment, metal processing equipment, etc., can solve the problem of no extrusion molding device for small-cell heat transfer tubes, etc., to improve the processing and manufacturing speed and manufacturing efficiency. , avoid the hydraulic system, improve the effect of processing and manufacturing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

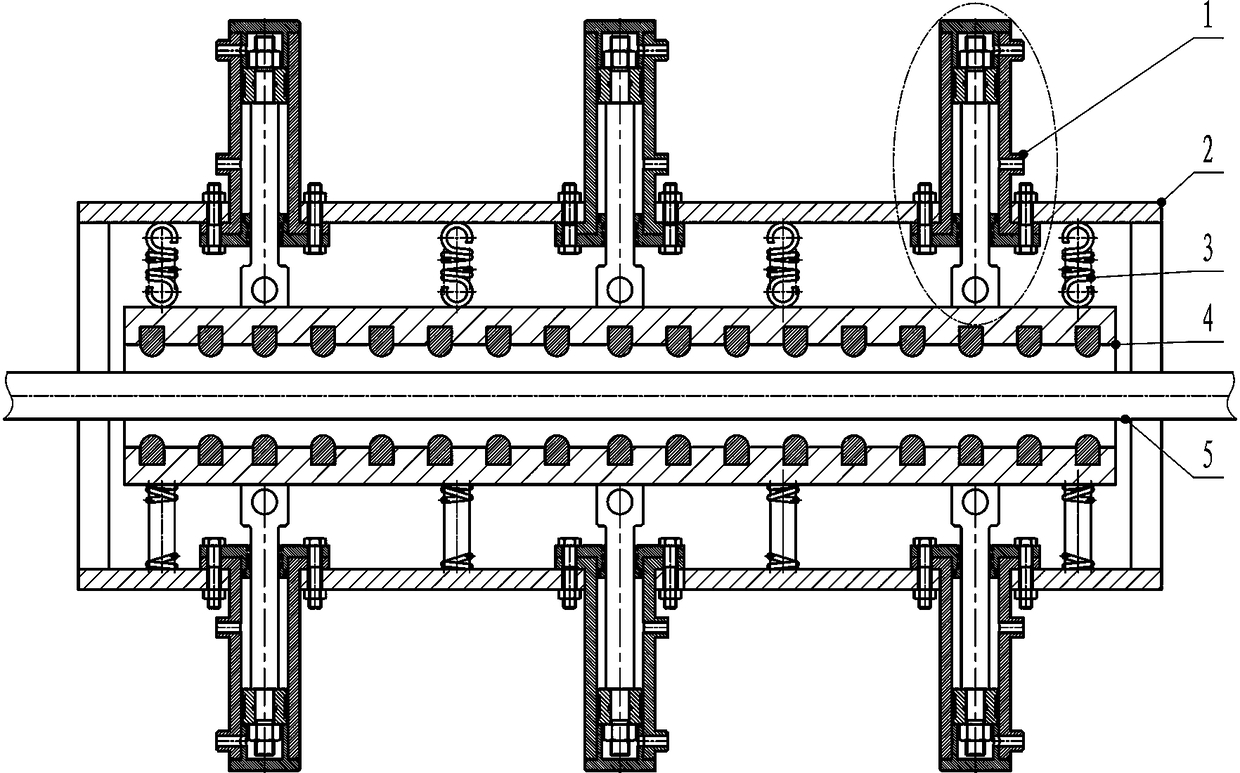

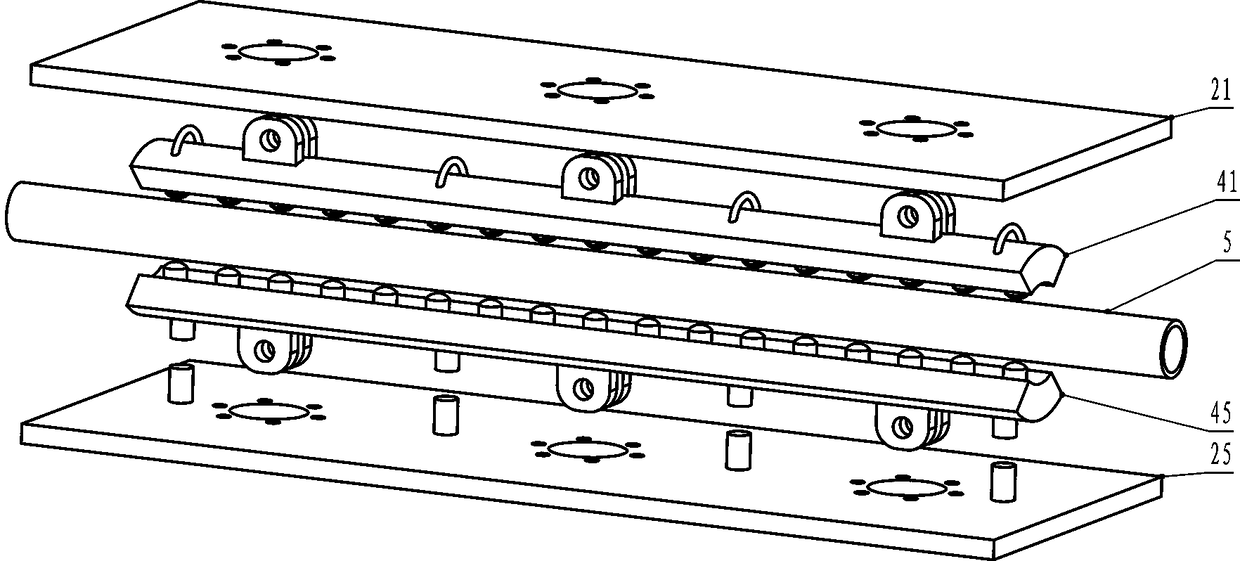

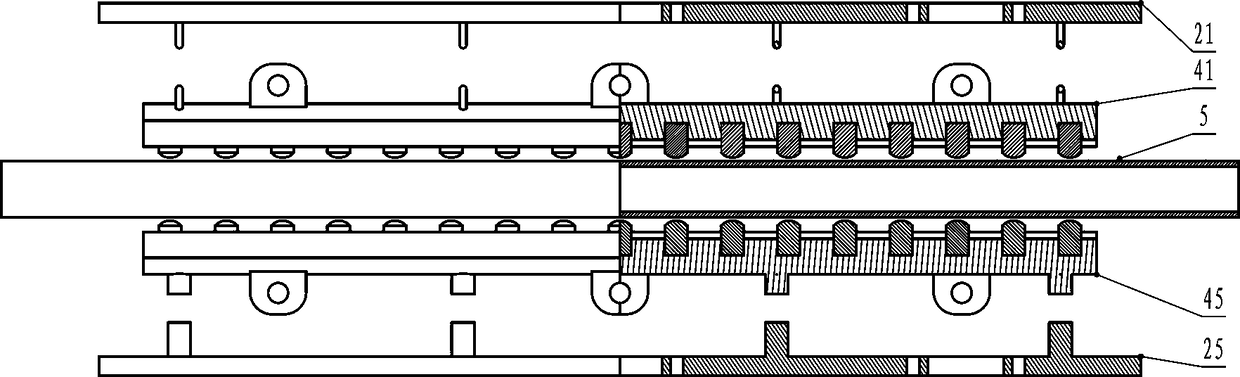

[0025] refer to Figure 1~Figure 4 , a hydraulic extrusion molding device for heat transfer tubes of dimples, which is composed of a hydraulic system 1, a support panel system 2, a spring system 3, and a pressure head system 4, and is used to extrude multiple dimples on the surface of a bare tube 5 at one time. cell. The hydraulic system 1 is bolted to the inner side of the support panel system 2 . The pin shaft on the lower side of the hydraulic system 1 is connected with the pressure head system 4 . A spring system 3 is installed between the pressure head system 4 and the hydraulic system 1 . The light pipe 5 is located at the center of the indenter system 4, and the light pipe 5 is axially installed with 2 to 8 rows of supporting panel systems. When working, multiple hydraulic cylinders provide driving force for the pressure head system 2, and the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com