Electromagnetic heating type extrusion molding device for butyl cell heat transfer tube

A technology for extrusion molding and heat transfer tubes, which is used in molding tools, heat exchange equipment, metal processing equipment, etc., and can solve the problem of fewer extrusion molding devices, small plastic molding limits, and uneven plastic flow of small-cell heat transfer tubes. and other problems, to achieve the effect of excellent plastic flow characteristics, good mold fit, and avoidance of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

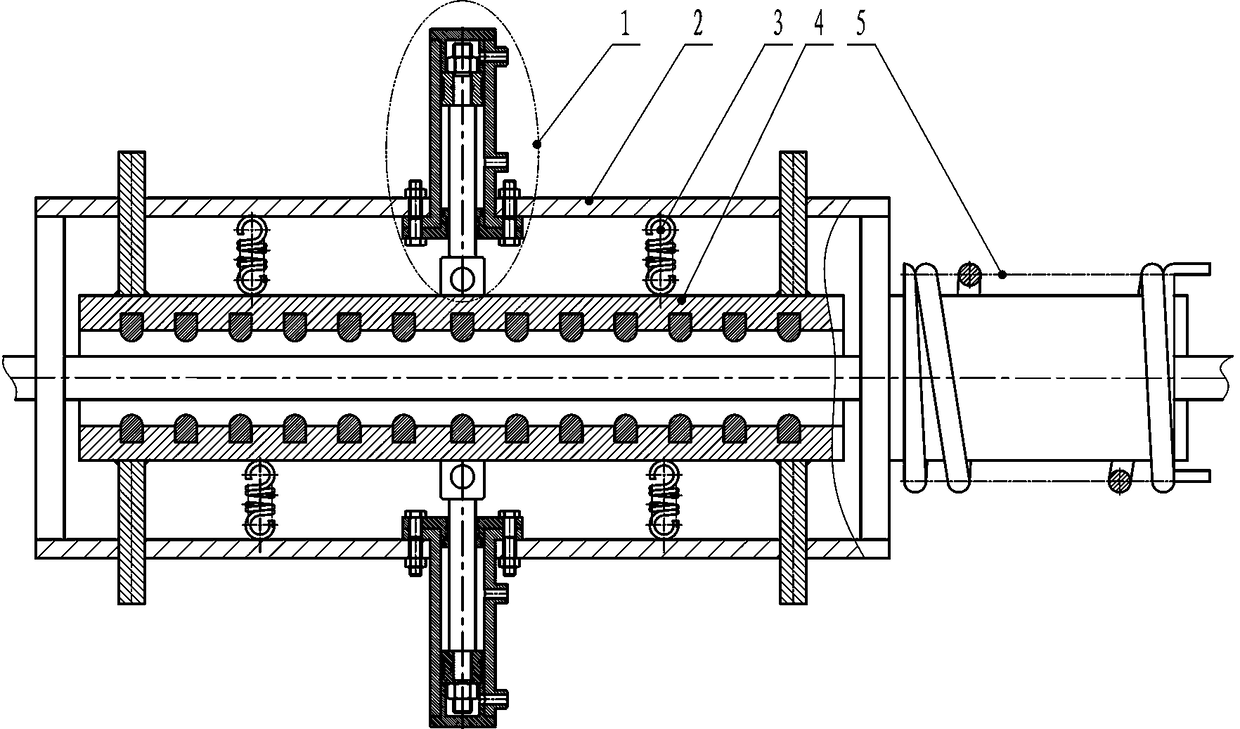

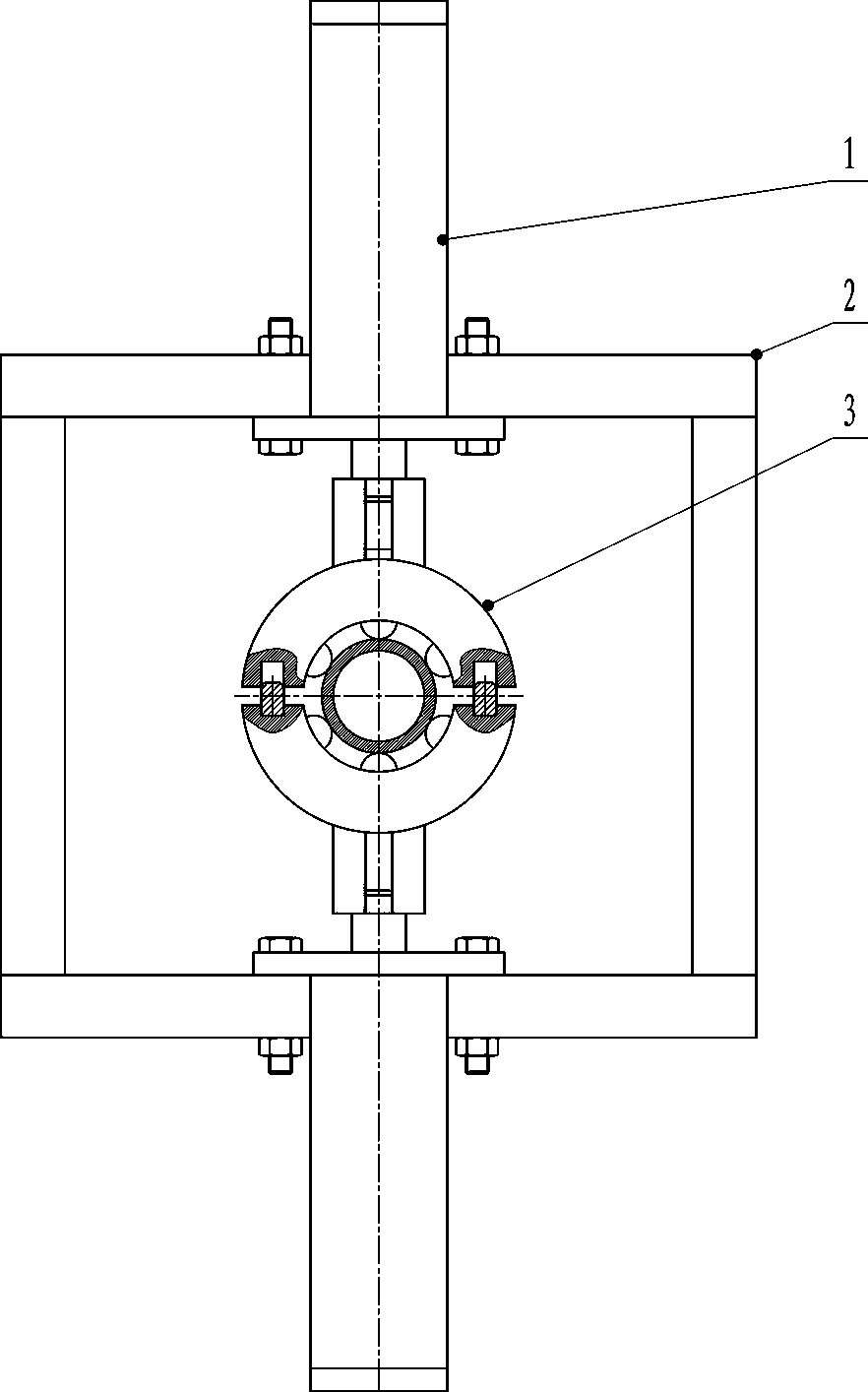

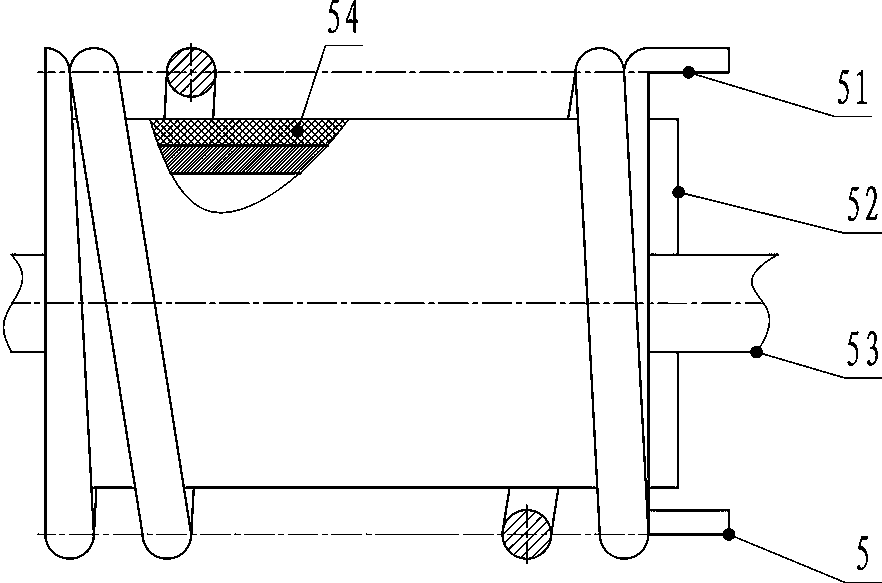

[0027] refer to Figure 1~Figure 2 , an electromagnetically heated extrusion molding device for a tyrex heat transfer tube, consisting of a hydraulic system 1, a support system 2, a reset system 3, a pressure head system 4, and a heating system 5, and is used to extrude on the surface of a bare tube 53 at one time Multiple clotting cells are formed. The support system 2 is bolted to the hydraulic system 1 . The lower side of the hydraulic system 1 is connected with a pressure head system 4 through a pin shaft. A reset system 3 is installed between the pressure head system 4 and the hydraulic system 1 . A heating system 5 is installed on the right side of the pressure head system 4 . The working principle of this device is: before extrusion molding, the heating system 5 first heats the light pipe 53 to soften the light pipe 53, and then sends the softened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com