Electrohydraulic power steering device and control method without torque sensor

A hydraulic power steering and steering control technology, which is applied to power steering mechanisms, steering mechanisms, fluid steering mechanisms, etc., can solve problems such as system stagnation, lower production efficiency, and increase the cost of power steering equipment, and achieve fast power response speed, The effect of improving production efficiency and facilitating centralized management and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

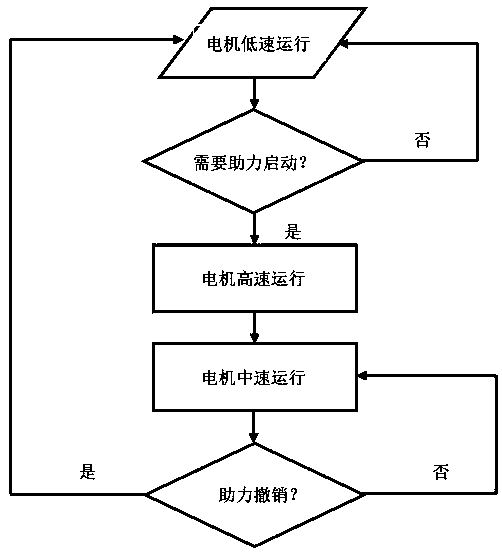

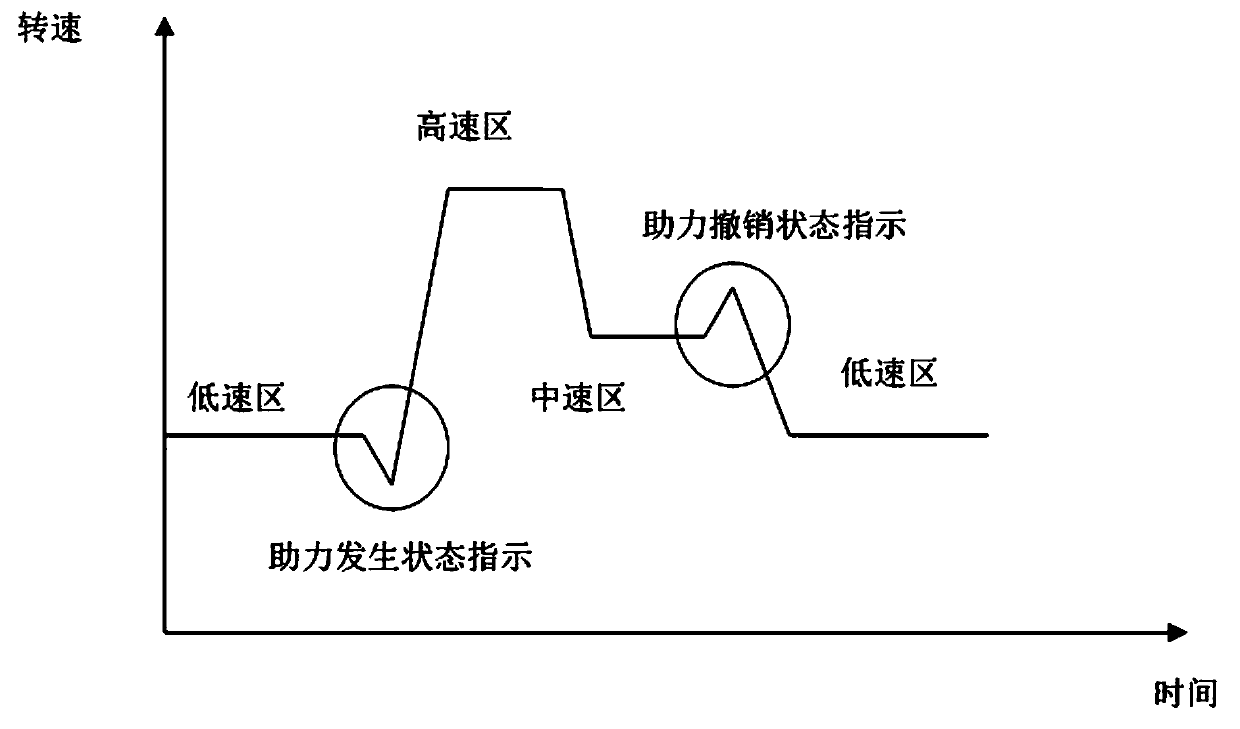

[0022] An electrohydraulic power steering device without a torque sensor, comprising a motor and a hydraulic pump whose power input end is connected to the output shaft of the motor, the hydraulic pump is connected to a hydraulic power steering column through a steering valve, the motor is a servo motor, and It includes a driver connected to the servo motor; the driver is provided with a processor and a memory, and a steering control program is stored in the memory, and when the steering control program is executed by the processor, it is judged whether the current need Steering assistance: When it is detected that the motor speed drops and the drop exceeds the preset first threshold, it is determined that power steering is currently required, and the motor is controlled to increase the speed to assist.

[0023] Such as figure 1 and 2 , the specific control method of the above-mentioned steering device is:

[0024] Set the motor in speed control mode.

[0025] When the vehi...

specific Embodiment 2

[0033] The difference between this embodiment and the specific embodiment 1 is that the specific values of the high speed, medium speed and low speed are determined by calculation:

[0034] Formulate a torque-speed relationship table, which records the torque T of the load borne by the motor load Correspondence between the first speed, the second speed and the third speed, the first speed (ie high speed) is higher than the second speed (ie medium speed), the second speed is higher than the third speed (ie low speed), usually For a fixed model, all the third rotation speeds in the table are the same.

[0035]Since the motor load torque and the torque value measured by the torque sensor in the prior art can be converted through the transmission ratio, those skilled in the art can refer to the motor speed control target in the existing scheme of using the torque sensor to achieve power assistance value, the torque-speed table required in this scheme can be obtained through sim...

specific Embodiment 3

[0042] The difference between this implementation and specific embodiments 1 and 2 is that the following principle is introduced: when it is determined that power steering is currently required, the greater the detected decrease in motor speed, the higher the motor speed will be when power is increased.

[0043] There is a close relationship between the speed of the vehicle and the reverse force of the wheels on the steering system. The steering wheel is heavy when the vehicle is running at low speed, and the steering wheel is lighter when the vehicle is running at high speed. High or low, and then by introducing the above principles, it can provide greater power assistance at low speeds and less power assistance at high speeds, so as to meet the nonlinear change trend of power steering torque at different speeds as much as possible, and increase driving comfort performance, as well as effective road awareness and reasonable control from the steering wheel.

[0044] The above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com