Noise control device arranged in water cooling tower

A water-drying tower and noise technology, which is applied in the field of noise prevention and control devices, can solve problems such as the influence of equipment ventilation and heat dissipation, and achieve the effects of reducing falling water noise and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

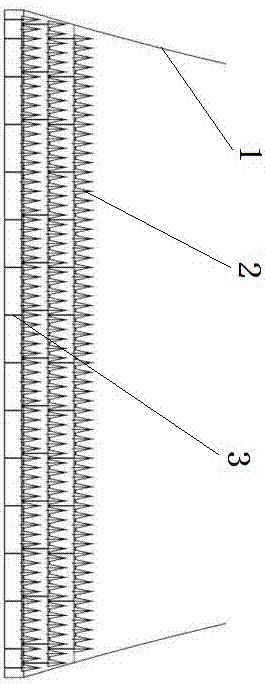

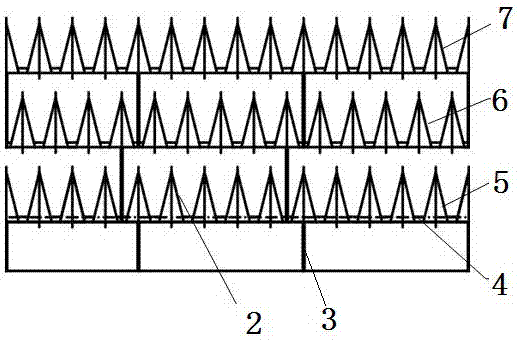

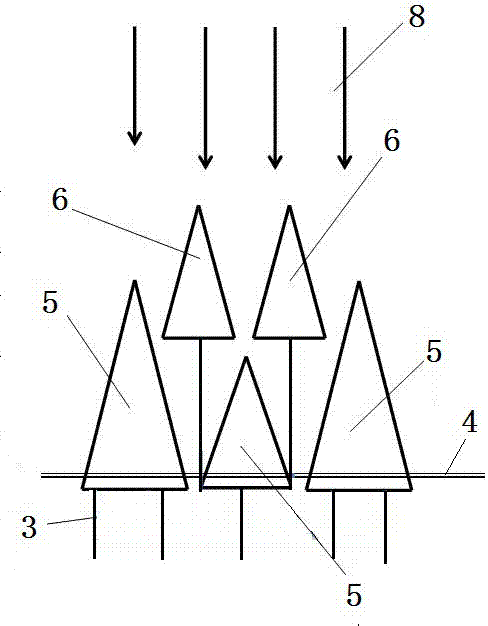

[0015] figure 1 , figure 2 As shown, three layers of conical mufflers 2 are set in a certain air-drying tower 1. The height of each conical muffler is 3 meters. The surface of the conical muffler is pasted with a rubber damping plate. Arrangement, from bottom to top, the first layer is provided with several conical sound attenuation bodies and the lower part of the cone sound attenuation bodies is lower than the level of the reservoir; Quantity, the second layer of cone sound attenuation body 6 is located above the first layer of cone sound attenuation body 5 and misplaced with the first layer of cone sound attenuation body; the third layer of cone sound attenuation body 6 is located Above and misaligned with the second layer of conical muffler.

[0016] The conical muffler is welded on the support frame 3 .

[0017] The first layer of conical muffler 5 is welded on the support of the first layer of supporting frame 3 below, and the legs of the supporting frame of the seco...

Embodiment 2

[0020] Three layers of regular tetrahedral anechoic bodies are installed in a water-drying tower. The surface of the tetrahedral anechoic bodies is pasted with damping and noise-reducing materials, and the next layer of anechoic bodies is arranged in the middle of the gap formed by the upper layer of anechoic bodies. , so that the water falling from the air-drying tower cannot directly fall on the horizontal surface of the water-drying tower reservoir, but is diverted to the lowermost muffler through the layering of the muffler. below the water level of the pool. The falling water flows downward in layers along the surface of the muffler, and falls on the next layer of muffler in layers. Finally, the falling water flows into the reservoir along the surface of the lowest muffler, and the falling water elevation is formed by the multi-layer muffler. The multiple reductions have greatly reduced the noise of falling water. At the same time, the damping and noise-reducing material ...

Embodiment 3

[0021] Embodiment 3: The section of the muffler in this embodiment is triangular in shape, and other structures are the same as in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com