Lead-through multi-stage step-down collector

A collector and lead technology, applied in the field of microwave electric vacuum devices, can solve problems such as restricting applications, and achieve the effects of saving space, increasing firmness, and reducing assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

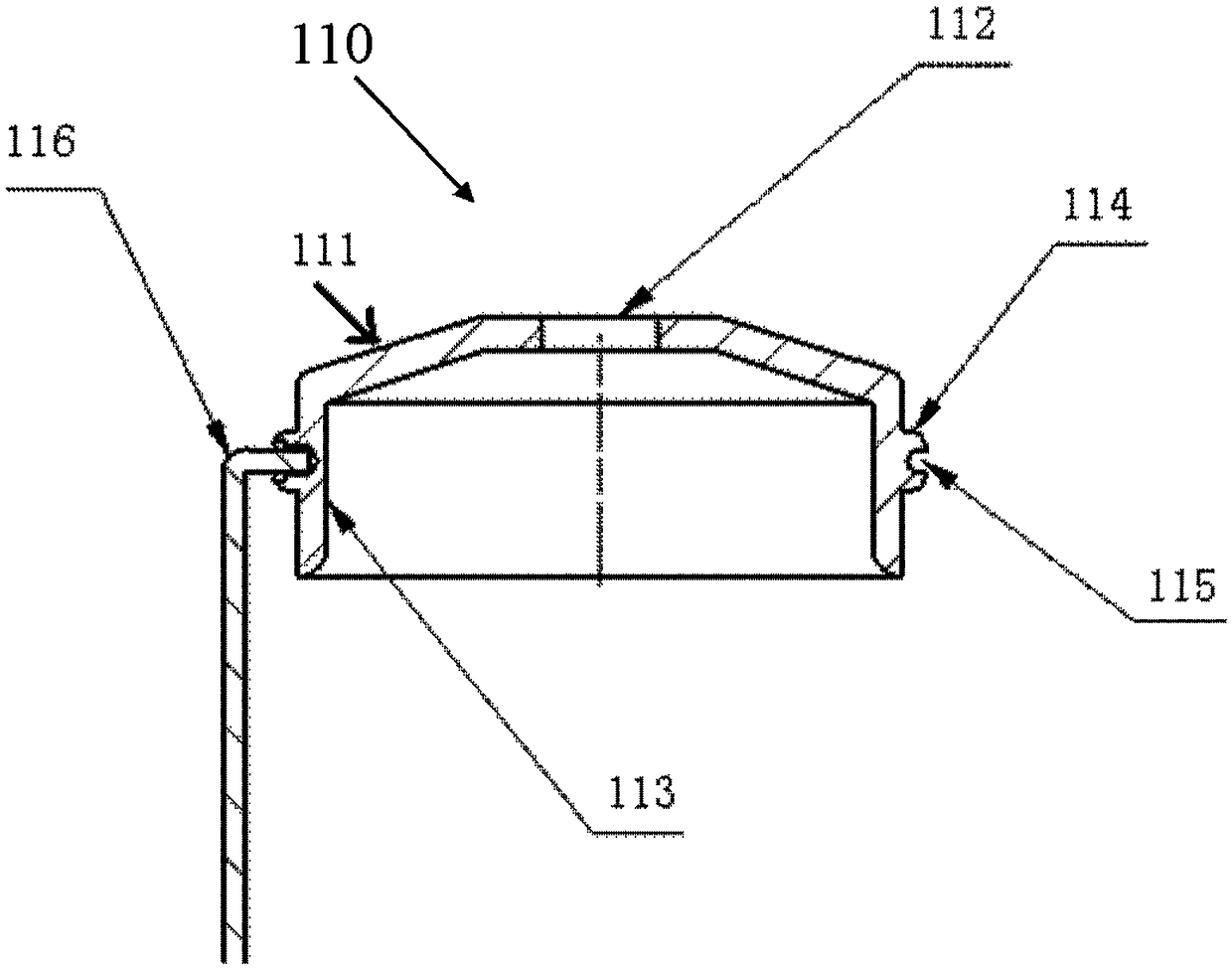

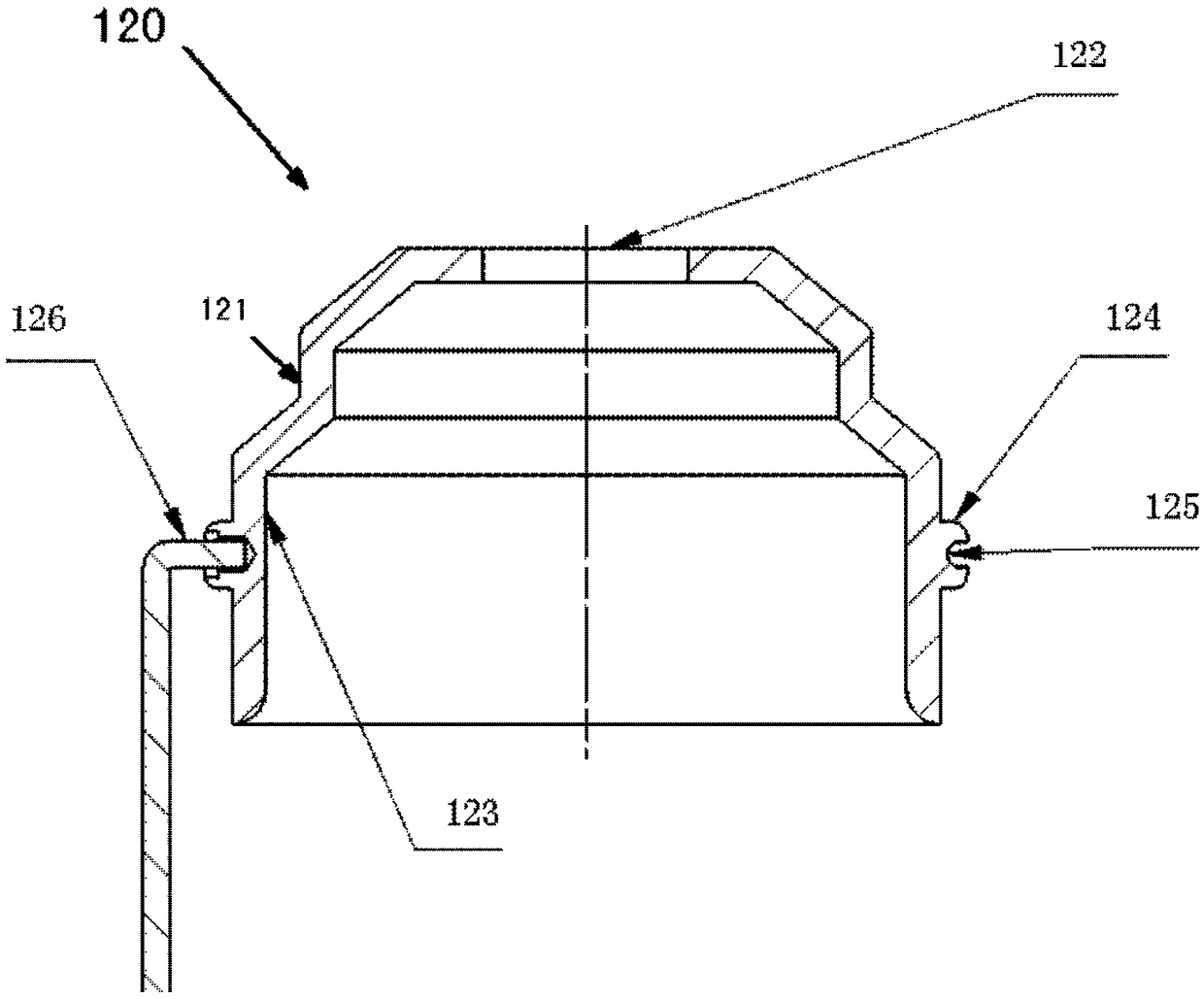

[0096] The disclosure reduces the difficulty of assembly by designing the insulating porcelain as a multi-lobe structure. Further, the lead wires of the collector electrodes at all levels are drawn out from the small holes in the middle of the insulating porcelain flaps, which not only increases the insulation performance but also saves space. In the case of the inner diameter, the outer diameter of the collector is minimized to achieve high efficiency under miniaturization.

[0097] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

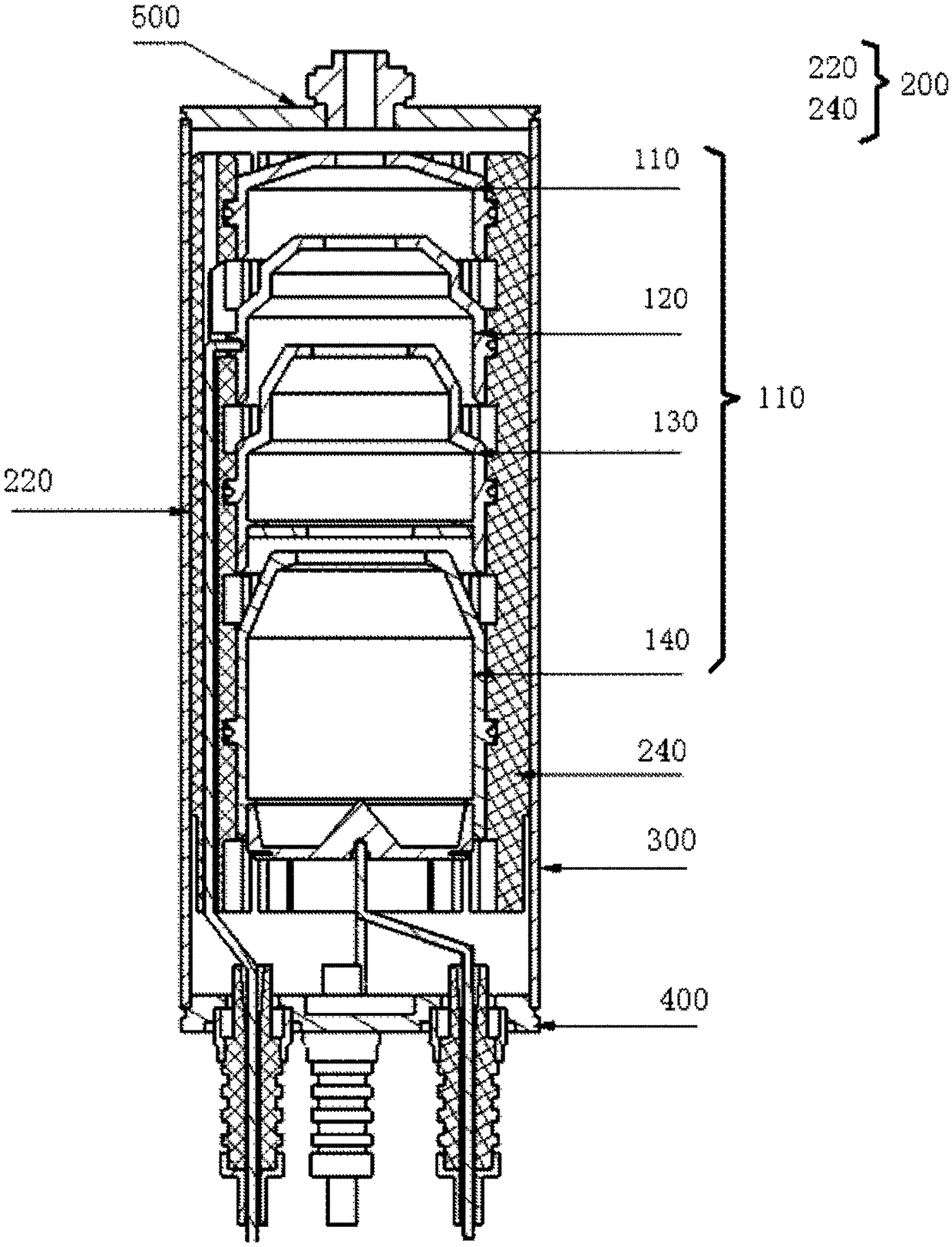

[0098] In an exemplary embodiment of the present disclosure, a lead-through type multi-stage buck collector is provided. figure 1 It is a cross-sectional view of a lead-through multi-stage buck collector according to an embodiment of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com