Method for reducing wear and damage of a tribological system of a transmission system

A technology of transmission and tribology, which is applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problems of transmission damage, a large amount of waste, and dissatisfaction of transmission vehicle users, and achieve the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

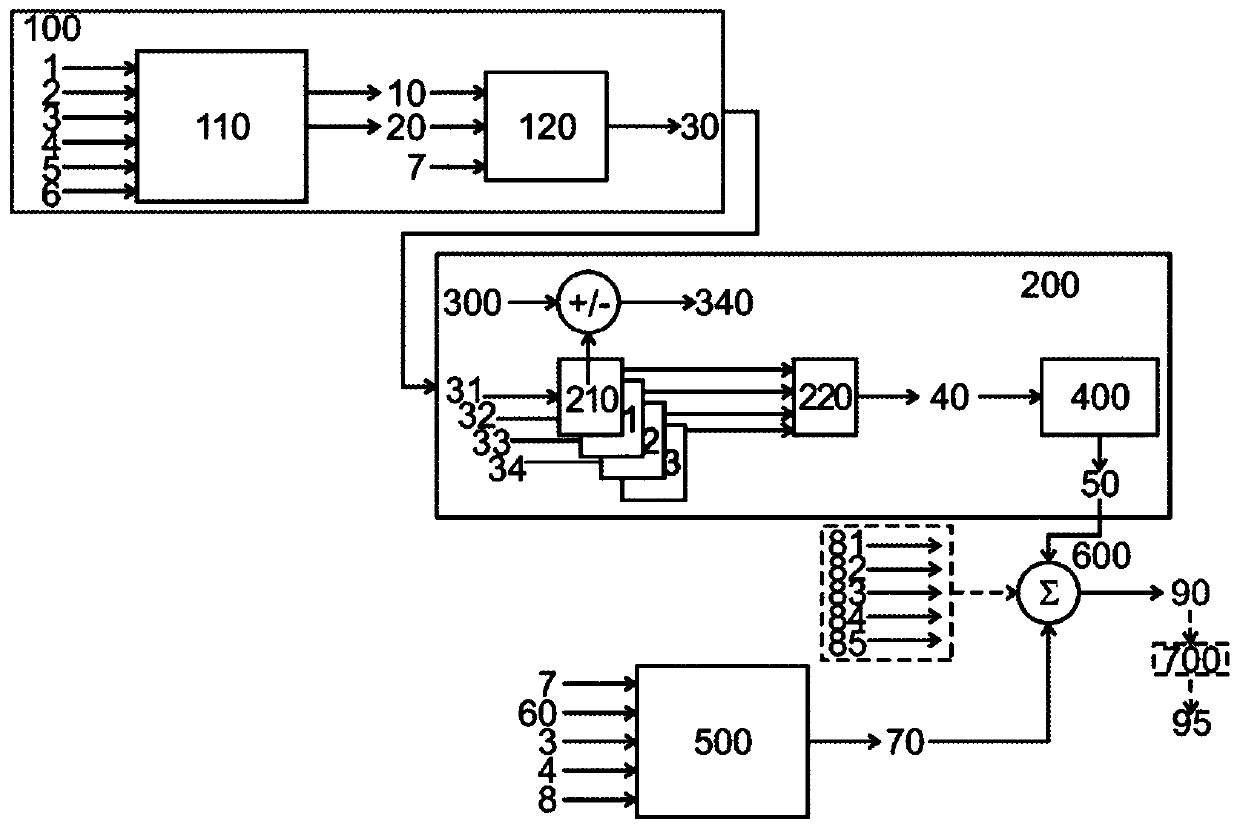

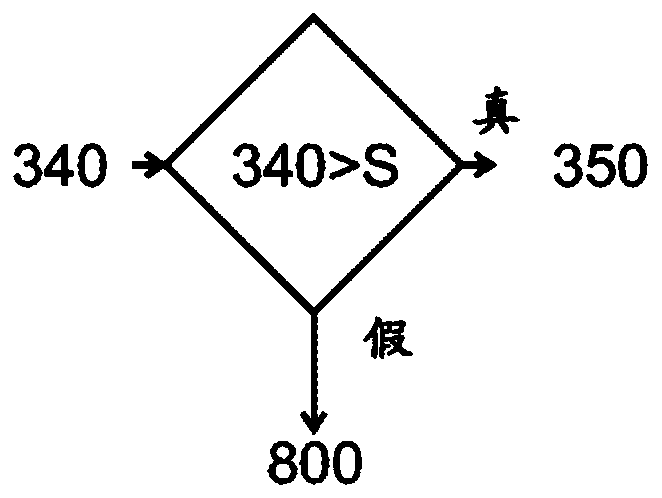

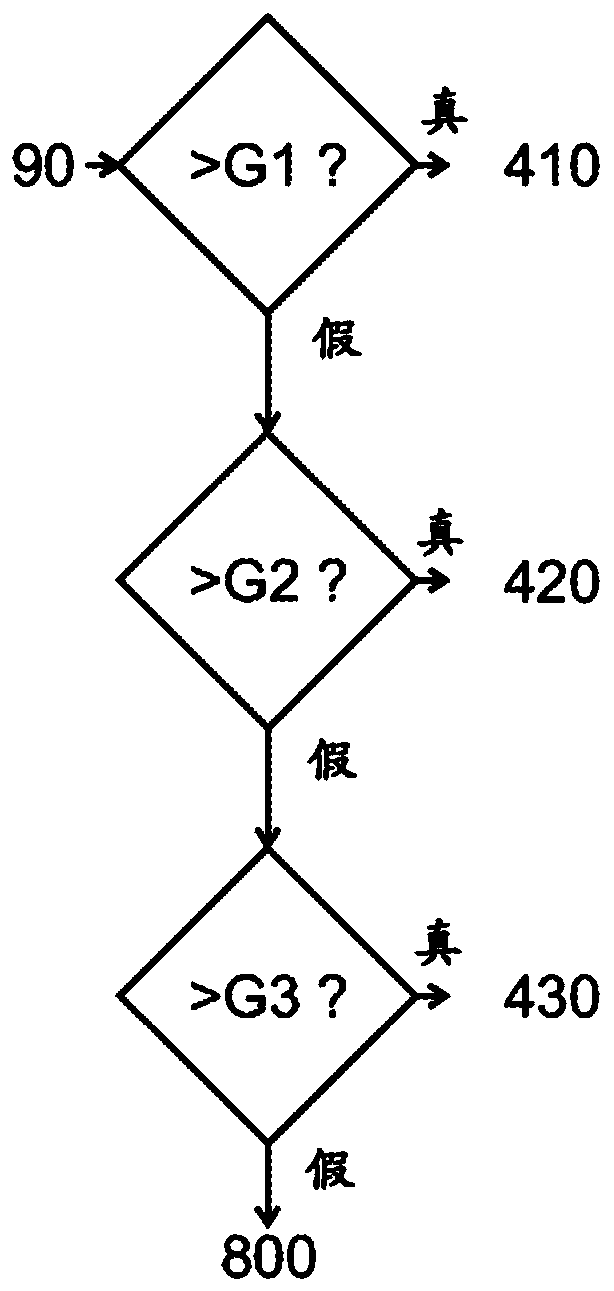

[0021] exist figure 1 An exemplary embodiment of the method according to the invention with a wear model of a tribological transmission system is shown in . The system of tribology is understood as describing friction, calculating and measuring the coefficient of friction, wear and the required lubrication between interacting surfaces in mutual motion. The wear model has an individual wear module 100 , the output signal of which is fed to a total wear module 200 . The wear factor 50 output by the overall wear module 200 is combined with the temperature factor 70 in a summing point 600 . The temperature factor 70 is calculated from a temperature module 500 which is based on various input variables. The oil sump temperature 7 , the estimated clutch temperature 60 , the setpoint rotational speed 3 of the transmission input shaft, the actual rotational speed 4 of the transmission input shaft and the coolant temperature 8 of the internal combustion engine are among the possible i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com