A device for derusting and polishing the inner wall of a magnetic tube

A technique for polishing devices and inner walls of tubes, which is applied in the direction of grinding drive devices, grinding/polishing equipment, and automatic grinding control devices, etc., which can solve the problem of high cost of abrasive grains, difficulty in large-scale promotion, and inability to realize rolling of abrasive grains and other issues to achieve the effect of low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

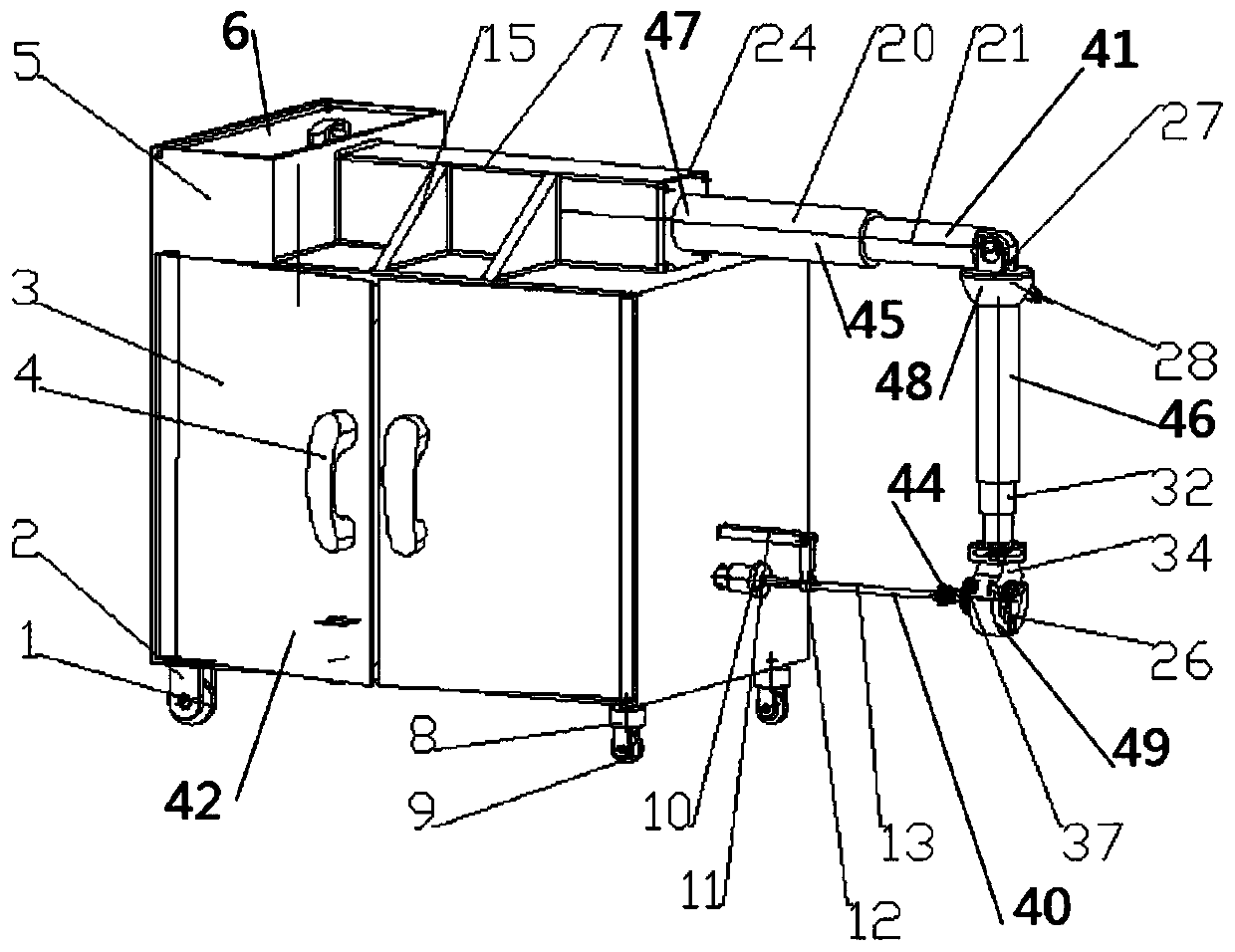

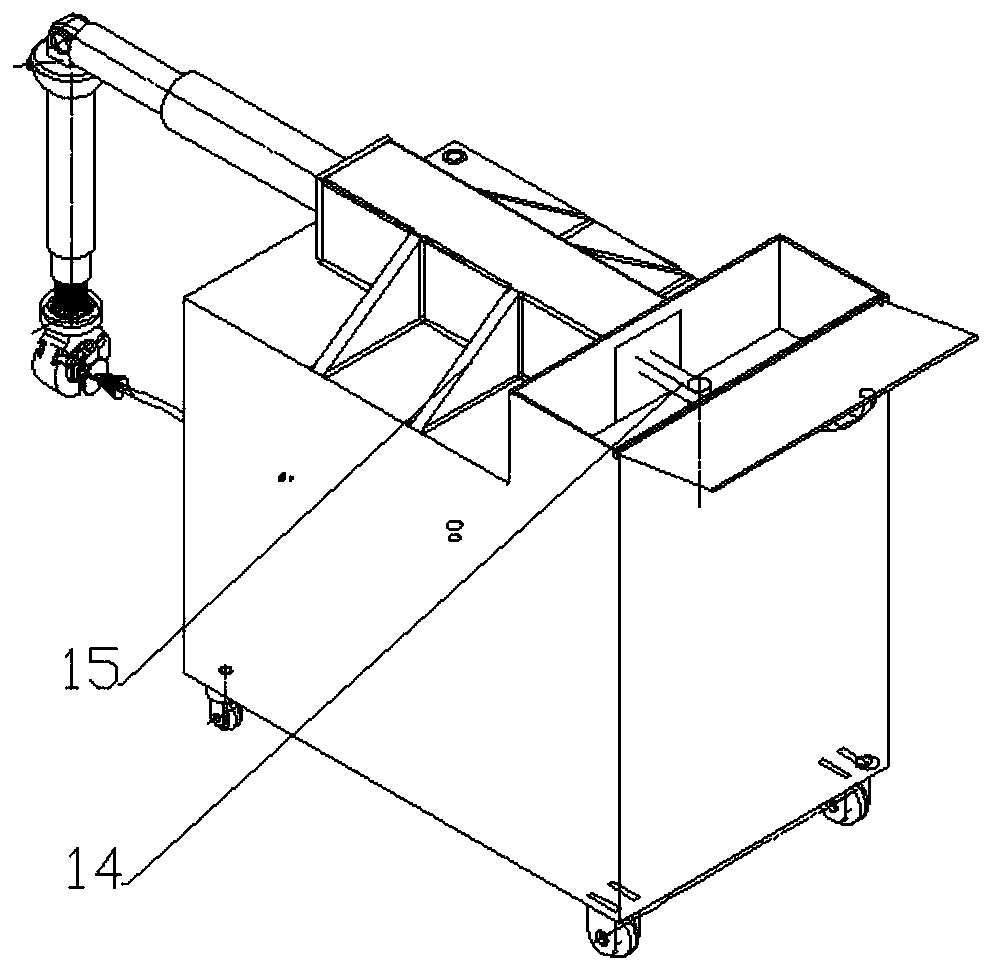

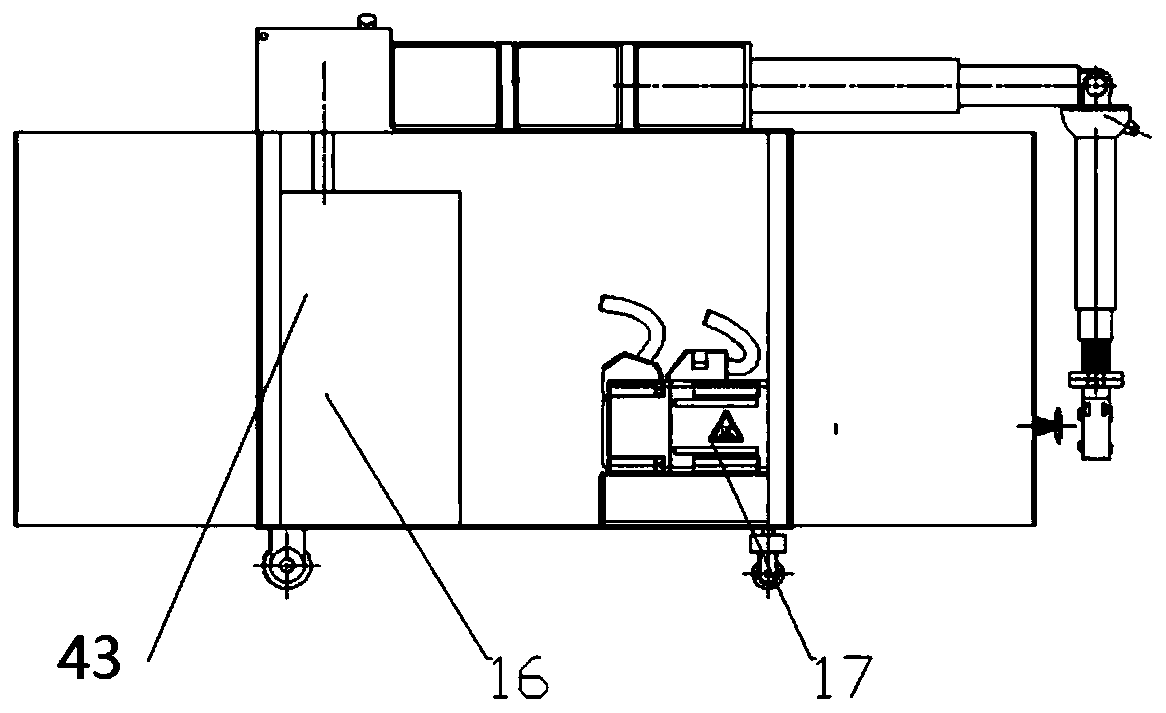

[0029] Such as Figure 1-3 As shown, a device for derusting and polishing the inner wall of a magnetic tube includes a body 42 , a derusting device 40 installed on the body 42 , a guide device 41 , and a control system 43 .

[0030] The derusting device 40 is composed of a motor 17, a flexible shaft 13, and a derusting head 44 connected in sequence. Such as Figure 4 As shown, the derusting head 44 includes a head main body 35 , a sponge cover 39 , and a derusting sheet 37 . Rust removal sheet 37 is enclosed within head main body 35 heads, and sponge cover 39 is enclosed within head main body 35 outsides, and the outer surface of head main body 35 is covered with a circle groove, and then prevents sponge cover 39 from coming off, and sponge cover 39 makes rust removal sheet 37 can be tightly attached to the inner wall of the magnetic conduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com