Application of a polyethylene polyamide composite film for carton handles

A polyethylene polyamide, carton handle technology, used in applications, household appliances, other household appliances, etc., can solve the problems of large volume, no elasticity, hardness and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of polyethylene polyamide composite film of the present embodiment is used for the application of carton handle, adopts the manufacturing process of following steps:

[0028] 1) Preparation of handle composite film: Put polyethylene particles into the first extruder and heat and melt at 120-200°C to extrude PE film; put polyamide particles into the second extruder and heat at 250-300°C Melting and extruding the PA film; the PE film and the PA film are compounded and connected by modified epoxy resin glue, and after cooling, a polyethylene polyamide composite film in the form of a PE / PA composite film is made, wherein the mass content ratio of PE and PA is 80:20, the thickness of polyethylene polyamide composite film is 0.3mm;

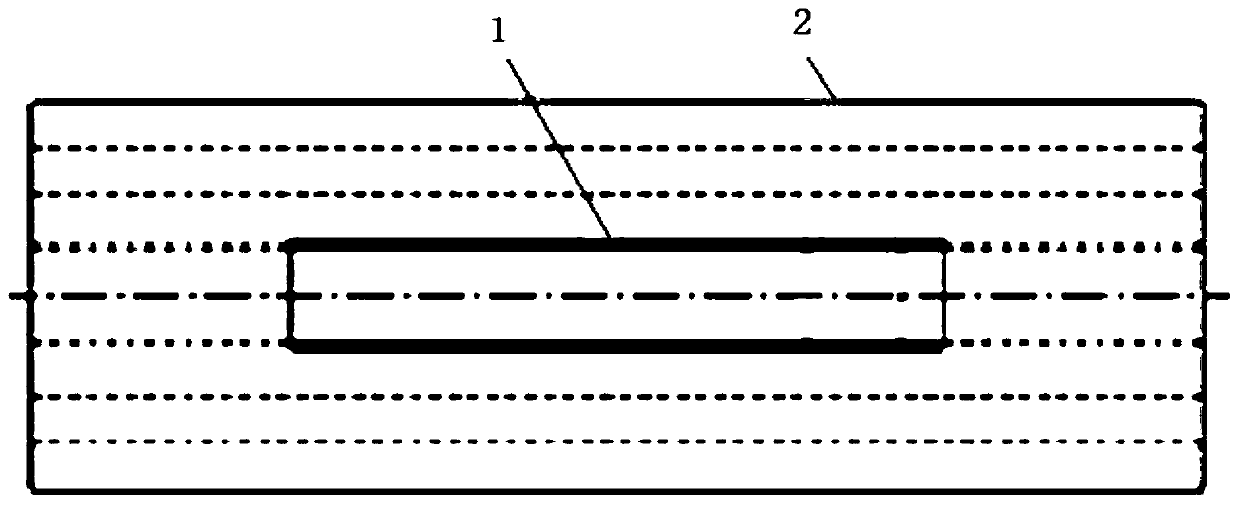

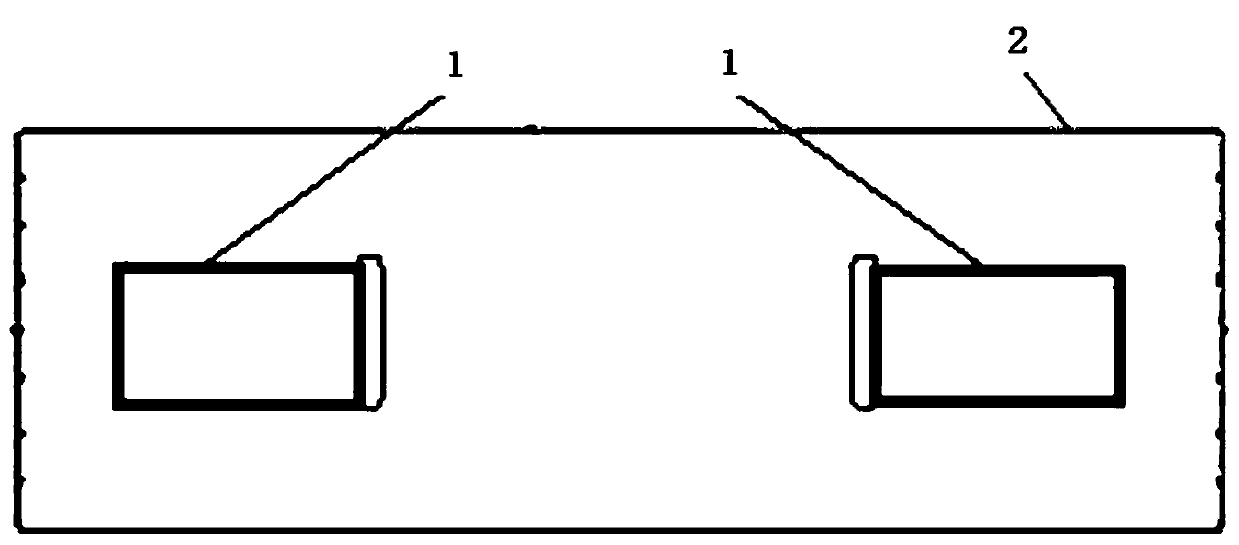

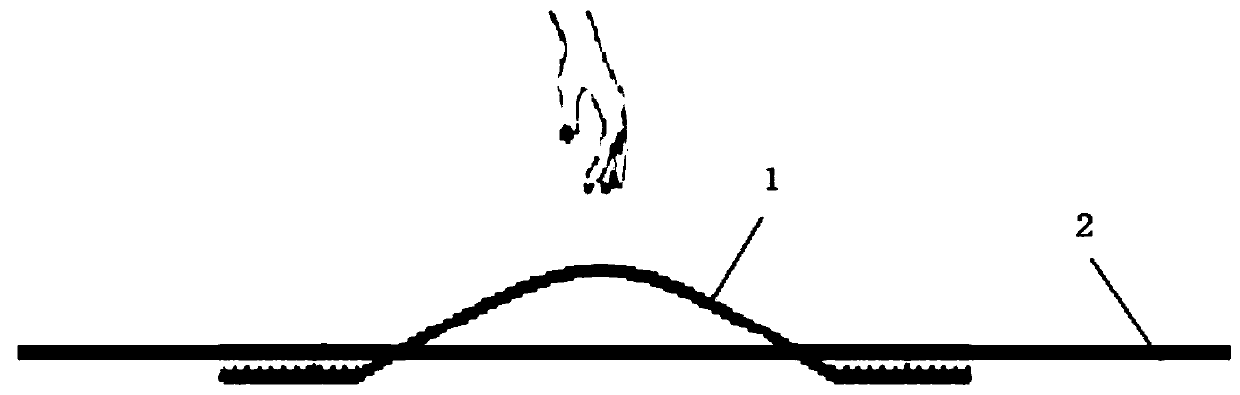

[0029] 2) Installation of the handle composite film: the polyethylene polyamide composite film is cut into a strip-shaped handle composite film 1 with a width of 5 cm and rolled into a composite film roll, and the composite film roll is co...

Embodiment 2

[0031] A kind of polyethylene polyamide composite film of the present embodiment is used for the application of carton handle, adopts the manufacturing process of following steps:

[0032] 1) Preparation of the handle composite film: Put the raw material polyethylene particles and raw material polyurethane particles into the multi-head extruder, extrude the PE film and the PA film at the same time after hot melting and connect them by hot melting, and make PE / PA / PE after cooling Polyethylene polyamide composite film in the form of composite film, wherein the mass content ratio of PE and PA is 75:25, and the thickness of polyethylene polyamide composite film is 0.3mm, which has higher strength and greater load bearing;

[0033] 2) Installation of the handle composite film: cut the polyethylene polyamide composite film into a strip-shaped handle composite film with a width of 2cm and wind it into a composite film roll, connect the composite film roll to the automatic handle-weari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com