Separation aeration type liftable membrane component

A membrane module and aeration-type technology, applied in the field of environmental engineering, can solve the problems such as the influence of the overall cleaning and maintenance efficiency of MBR reactors, achieve the effect of improving the overall cleaning and maintenance efficiency and ensuring the structural stability of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

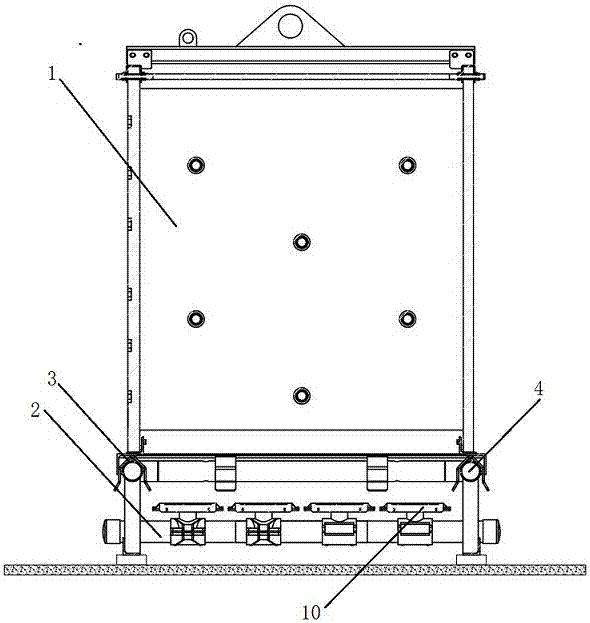

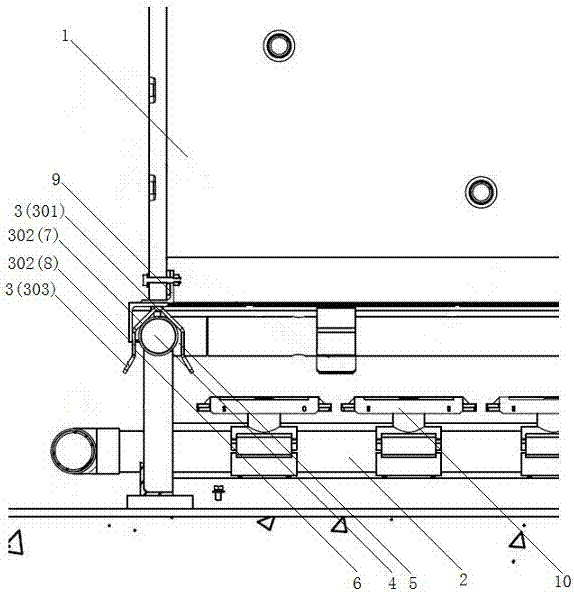

[0034] Such as figure 1 versus figure 2 A separation and aeration type liftable membrane module is shown, which includes a membrane module 1 and an aeration system 2 that are opposite to each other in a vertical direction; the separation and aeration type liftable membrane module includes a vertical The first connecting mechanism 3 and the second connecting mechanism 4 opposite to each other in the straight direction are arranged on the opposite end surfaces of the membrane module 1 and the aeration system 2, and the first connecting mechanism 3 is arranged on the bottom end of the membrane module 1. Above, the second connecting mechanism 4 is arranged on the upper end of the aeration system 2; the first connecting mechanism 3 includes a connecting groove 5 opposite to the second connecting mechanism 4, and the second connecting mechanism 4 It can extend to the inside of the connecting groove body 5, and the inner wall of the connecting groove body 5 includes at least two conne...

Embodiment 2

[0040] As an improvement of the present invention, the bottom end of the clamping end 302 is provided with a guiding end 303, and the distance between the guiding ends 303 on two adjacent clamping ends 302 gradually increases in the extending direction. Using the above technical solution, it can make the first connecting mechanism move relative to the second connecting mechanism, through the setting of the guiding end to form a guiding process, so as to ensure that the second connecting mechanism enters the two clampings in the first connecting mechanism The inside of the end, so that when the staff realizes the movement of the membrane module relative to the aeration system, the relative position and connection relationship can be automatically corrected and guided under a certain horizontal offset state, so that the membrane module is relatively The assembly efficiency and accuracy of the aeration system are improved.

[0041] The remaining features and advantages of this embod...

Embodiment 3

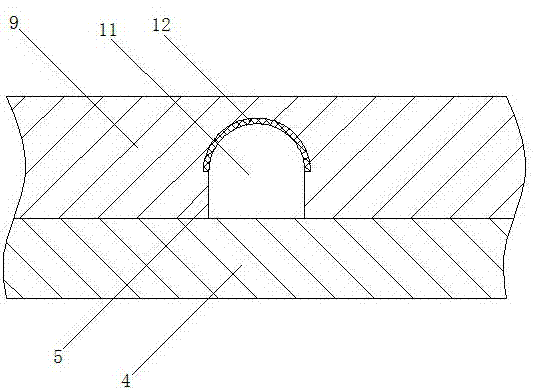

[0043] As an improvement of the present invention, the second connecting mechanism 4 adopts a cylindrical structure whose axial direction is parallel to the clamping end 302 of the first connecting mechanism 3; the diameter of the second connecting mechanism 4 is at least the same as that of the first connecting mechanism. The maximum distance between the two clamping ends 302 among 3 is equal. With the above technical solution, the contact area between the second connecting mechanism and the first connecting mechanism can be improved, so as to further improve the clamping effect.

[0044] The remaining features and advantages of this embodiment are the same as those of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com