X-ray machine malfunction maintenance method, device and system

A fault repair and X-ray machine technology, applied in the field of X-ray machines, can solve the problems of no solution, high maintenance cost, and inability to use equipment, etc., to achieve the effect of improving convenience and experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

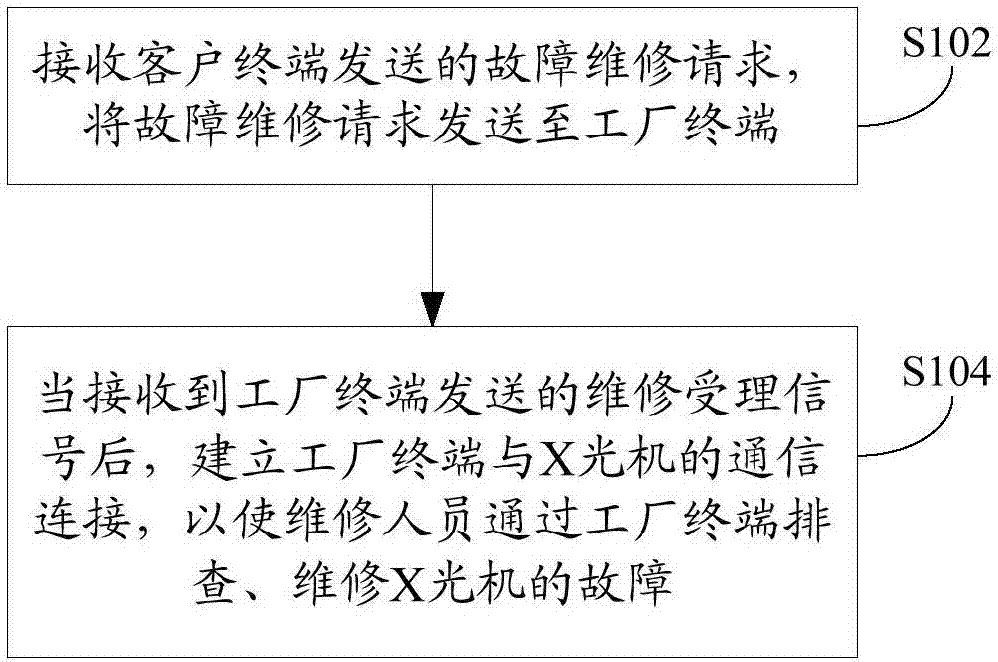

[0030] see figure 1 The flow chart of the first X-ray machine fault maintenance method shown; the method is executed by a server, the server is respectively connected to the X-ray machine, the client terminal and the factory terminal, and the X-ray machine is bound to the client terminal; the method includes the following step:

[0031] Step S102, receiving the fault repair request sent by the client terminal, and sending the fault repair request to the factory terminal; wherein, the fault repair request includes the identification information of the X-ray machine bound to the client terminal;

[0032] The above-mentioned X-ray machine can be a C-arm X-ray machine; the X-ray machine is provided with a communication module for connecting to a remote server through the network; the X-ray machine can be bound to the client terminal through the user's identity information; the above-mentioned The fault repair request includes identification information to be repaired, and may als...

Embodiment 2

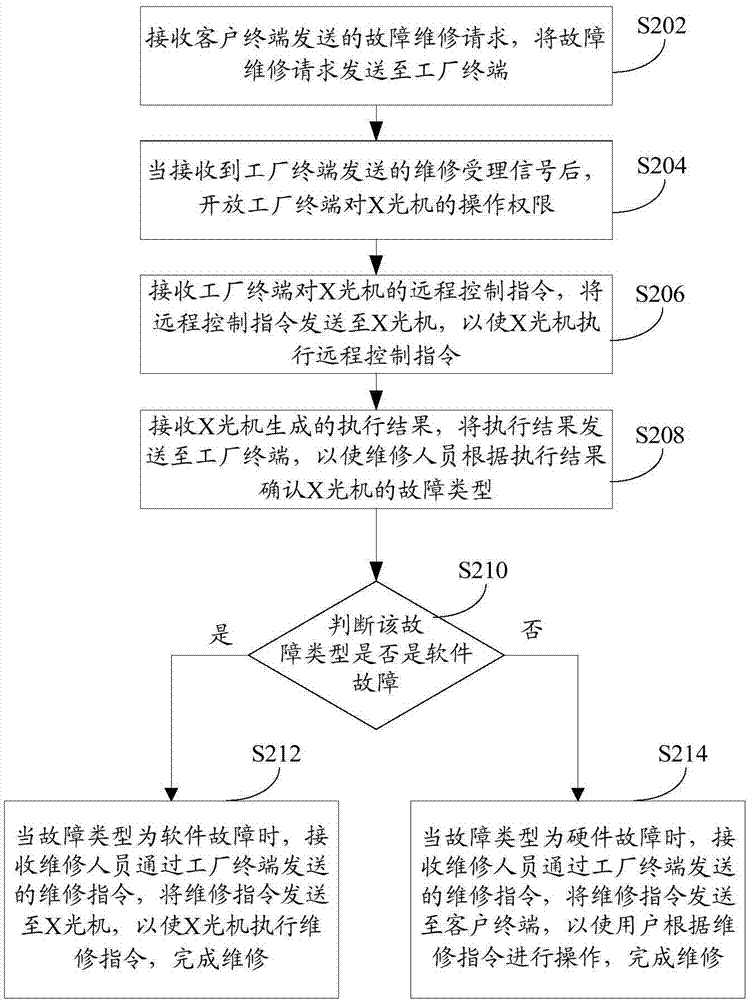

[0037] see figure 2 The flow chart of the second X-ray machine failure maintenance method shown; the method is realized on the basis of the X-ray machine failure maintenance method provided in Embodiment 1; the method is executed by a server, and the server communicates with the X-ray machine, The client terminal is connected to the factory terminal, and the X-ray machine is bound to the client terminal; the above method includes the following steps:

[0038] Step S202, receiving the fault repair request sent by the client terminal, and sending the fault repair request to the factory terminal; wherein, the fault repair request includes the identification information of the X-ray machine bound to the client terminal;

[0039] Step S204, after receiving the maintenance acceptance signal sent by the factory terminal, open the operation authority of the factory terminal to the X-ray machine; the operation authority of the factory terminal to the X-ray machine can be opened in an ...

Embodiment 3

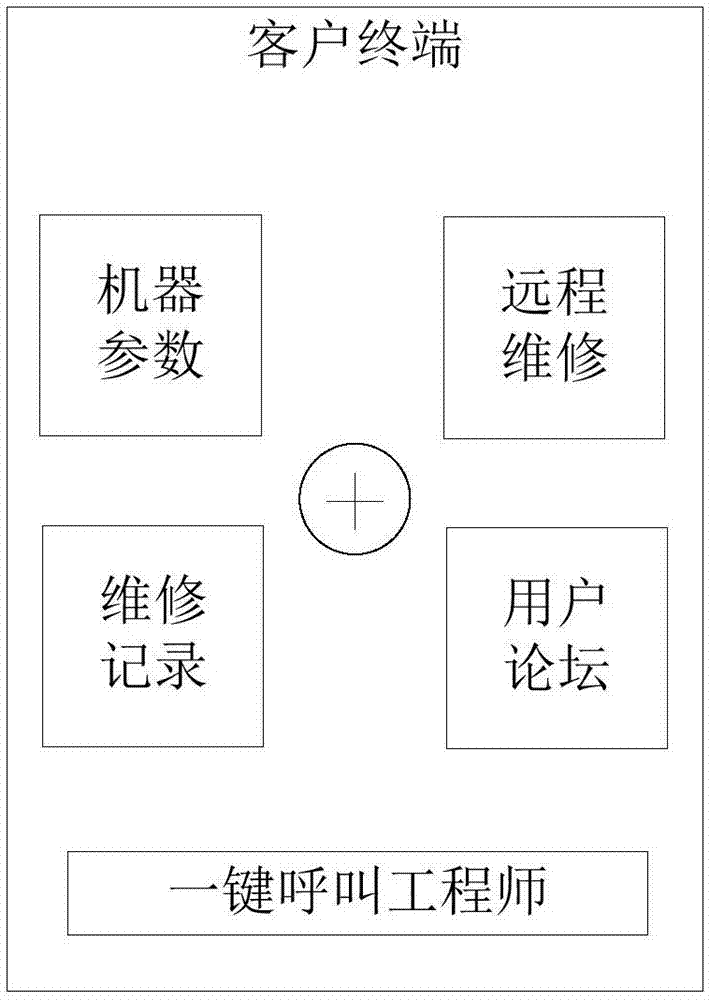

[0062] Corresponding to the X-ray machine fault maintenance method provided in the above-mentioned embodiment 1 or embodiment 2, see image 3 A schematic diagram of the interface structure of a client terminal shown, and Figure 4 A schematic diagram of the interface structure of a factory terminal is shown; the application program installed on the client terminal and the factory terminal can be implemented through the Android system or the IOS system, and the user or maintenance personnel can realize various state parameters of the X-ray machine through the application program. monitor.

[0063] The above-mentioned client terminal mainly includes four basic functions such as machine parameters, remote maintenance, maintenance records and user forums, as well as the function of calling an engineer with one key; specifically, by clicking "Machine Parameters", the client can display the C-arm X in real time. Each state parameter of the optical machine, the user can also perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com