Automatic production device of graphene far-infrared electrothermal films

A production equipment, infrared electricity technology, applied in electric heating devices, ohmic resistance heating, non-electric variable control and other directions, can solve the problems of reduced production efficiency, lack of equipment supervision system, low product qualification rate, etc., to ensure physical and mental health, control Advanced system and the effect of reducing staffing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

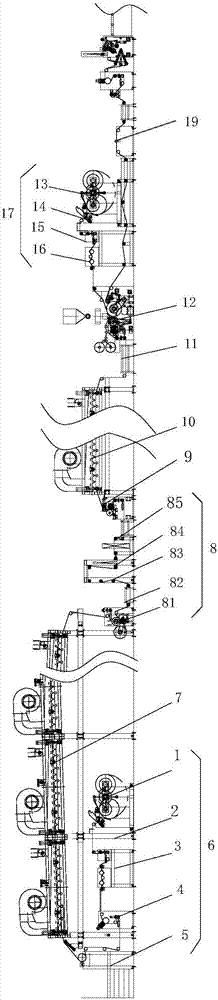

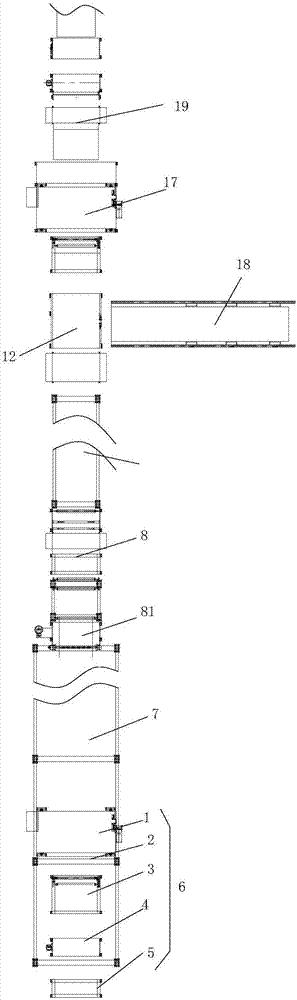

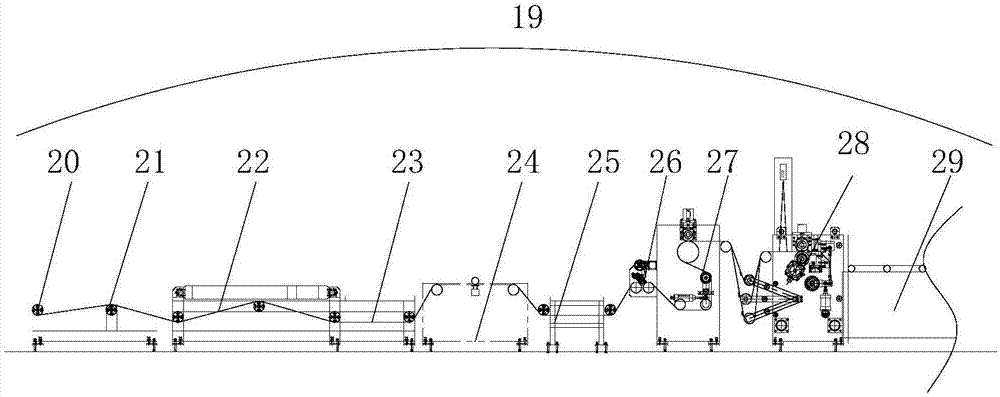

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0028] refer to Figure 1-3, a graphene far-infrared electrothermal film automatic production equipment, including a coating unit 6, a first oven 7 is arranged above the coating unit 6, and one end of the first oven 7 and one end of the coating unit 6 are located on the same horizontal line, and the raw materials pass through After coating, it is transferred to the first oven 7 for drying treatment. An online detection unit 8 is also provided under the other end of the first oven 7 to detect the dried material. One side of the online detection unit 8 is also A conductive glue gluing machine 9 is provided to glue the detected materials, and transfer the glued material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com