Multidimensional numerical control high speed drilling machine

A high-speed drilling machine, multi-dimensional technology, applied in the direction of large-scale fixed members, clamping, support, etc., can solve the problem of not being suitable for processing such workpieces, and achieve the effect of facilitating processing operations, reducing labor intensity, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

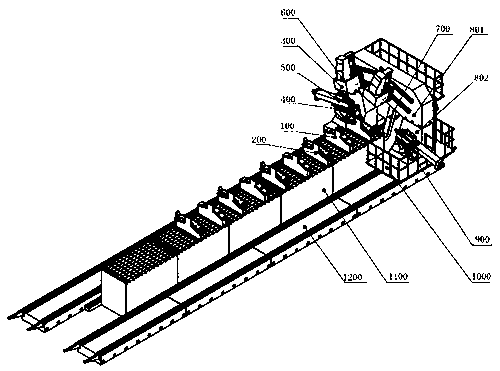

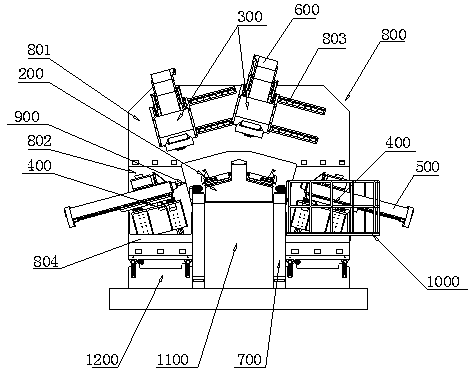

[0039] Such as figure 2 , image 3 , Figure 9 As shown, a multi-dimensional numerical control high-speed drilling machine includes a locking fixture 200 for locking the short side of a multi-dimensional special-shaped workpiece, a support fixture 100 that supports the workpiece and absorbs and fastens it, and a corner device 400 that provides a corner function for the BT40 power head. The BT40 power head 500 for drilling on the short side, the power head auxiliary pressing mechanism 300 installed on the BT50 power head 500 for pressing the workpiece, the BT50 power head 600 for drilling the long side, and the waste The chip conveyor 700 that collects and sends out the machine tool, the gantry 800 that loads the power head (including the beam 801 that loads two BT50 power heads and provides rigid support for the machine tool, and the column 802 that loads two BT40 power heads and supports the beam) , detection device 900 for detecting workpiece deformation to improve machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com