Winding no-bottom-wrinkle receiving mechanism

A technology without bottom wrinkle and mandrel, which is applied in winding strips, thin material handling, transportation and packaging, etc. It can solve the problems of bottom wrinkle caused by changing rolls and splicing materials, difficulty in meeting high-efficiency production, and slowing down of machine speed. , to achieve the effect of eliminating the curling of the base material end surface, reducing the curling phenomenon of the base material, and reducing the waste of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

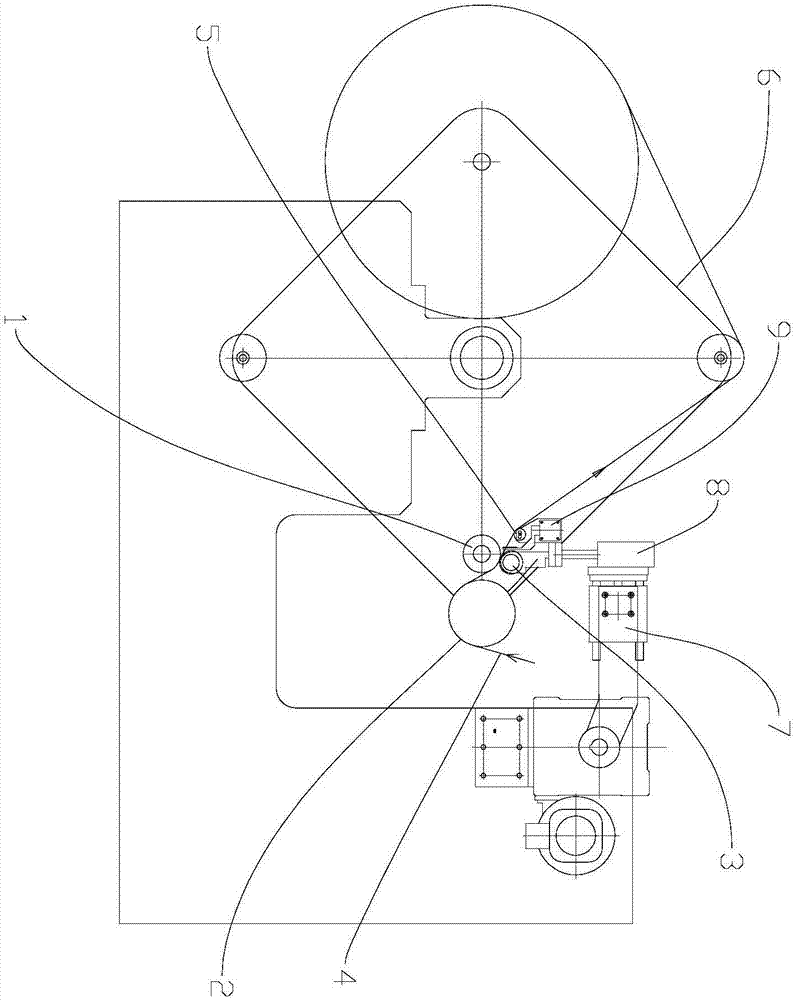

[0018] refer to figure 1 , the present invention is a winding bottomless wrinkle splicing mechanism, characterized in that it includes:

[0019] rotatable mandrel 1;

[0020] The mounting seat 2 is driven by a first driving device to be able to lift and move forward and backward;

[0021] The pressure roller 3 is rotatably installed on the mounting seat 2, and the substrate 4 passes between the pressure roller 3 and the mandrel 1;

[0022] The cutting knife 5 is driven by a second driving device to move along the width direction of the substrate 4 .

[0023] Along the traveling direction of the base material 4, the starting position of the pressure roller 3 is located at the back and upper side of the mandrel 1, and the pressure roller 3 has two kinds of moving trajectories, one of which is up and down (for bonding the base material 4 to the mandrel 1 above), the second is the arc track around the mandrel 1; in the present invention, the base material 4 is pasted on the man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com