Additive Manufacturing Scaffold Combined with Gel Casting Method for Porous Calcium Phosphate Ceramics

A porous calcium phosphate, additive manufacturing technology, applied in ceramic products, manufacturing tools, additive processing and other directions, can solve the problems of mechanically unstable ceramic bodies, poor adhesion, ceramic cracking, etc., to achieve good biological properties, Good mechanical properties, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

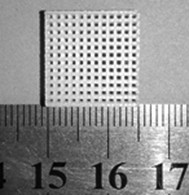

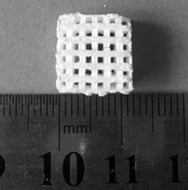

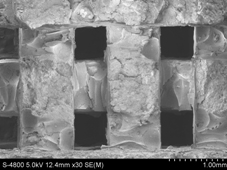

[0031] According to step A) of the present invention, using fused deposition modeling (FDM) additive manufacturing printer and polylactic acid as consumables to manufacture such as figure 1 A polylactic acid porous scaffold template with a pore size of 500 microns and through holes;

[0032] Step B), put 3.0 grams of water, 3.0 grams of hydroxyapatite particles, 0.025 grams of dispersant sodium polyacrylate, 0.1 grams of binder hydroxypropyl methylcellulose, 0.2 grams of acrylamide monomer, 0.033 grams of N,N - methylene-bisacrylamide crosslinking agent, 0.010 g of ammonium persulfate and 0.015 g of tetramethylethylenediamine are fully mixed to obtain a mixture M;

[0033] Step C), pouring the mixture M into the porous stent template, and then reacting for 24 hours in a nitrogen protection environment with a temperature of 50°C and a humidity of 90%, to obtain a porous stent template / ceramic body;

[0034] Step D), soak the porous support template / ceramic body in dichlorometh...

Embodiment 2

[0037] Using ABS as the printing consumable, other preparation conditions were the same as in Example 1, and a porous hydroxyapatite ceramic with a pore size of 400 microns and three-dimensionally interconnected pores was obtained.

Embodiment 3

[0039]Tricalcium phosphate was used as calcium phosphate particles, and other preparation conditions were the same as in Example 1 to obtain porous tricalcium phosphate ceramics with pores of 400 microns and three-dimensionally interconnected pores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com