Preparation method of dopamine-modified glass fiber-epoxy resin composite material

A glass fiber and epoxy resin technology, which is applied in the field of composite material preparation, can solve problems such as research involving few reports, and achieve the effects of low cost, simple reaction process and mild environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

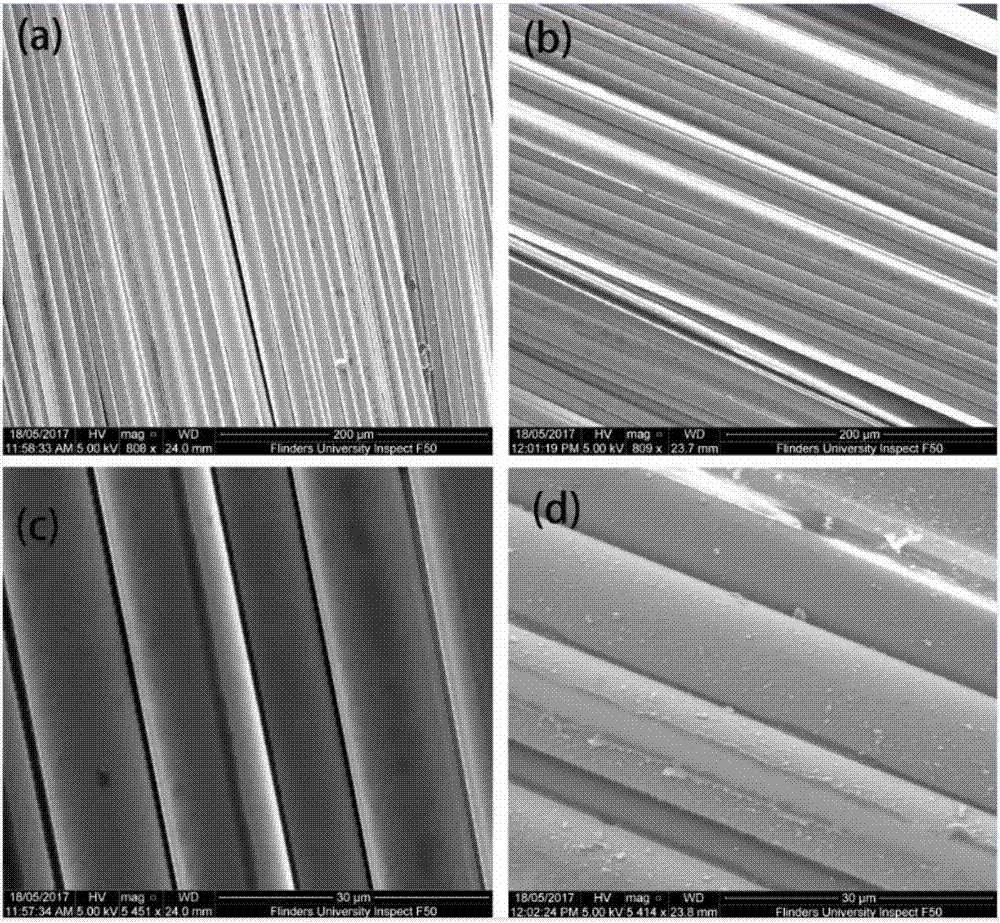

Image

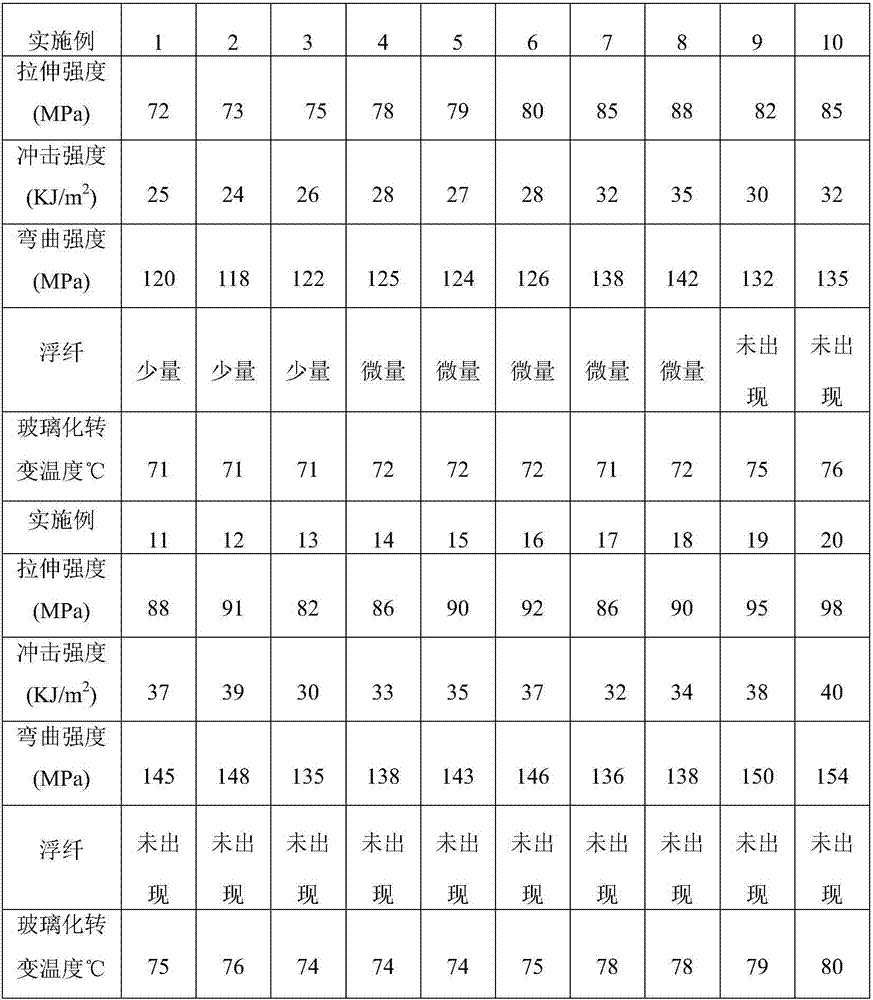

Examples

Embodiment 1

[0026] A preparation method of dopamine modified glass fiber-epoxy resin composite material, comprising the following steps:

[0027] Step 1. Prepare a dopamine hydrochloric acid solution with a concentration of 3 mg / mL, adjust the pH to 8, then soak the glass fiber in the dopamine hydrochloric acid solution, shake it in the dark for 12 hours, then wash the glass fiber and dry it at 30°C to obtain dopamine-modified Sexual glass fiber; the mass volume ratio of the glass fiber to the dopamine hydrochloric acid solution glass fiber is 1:5;

[0028] Step 2. Add 50 parts of bisphenol A epoxy resin and 10 parts of dopamine-modified glass fiber into the mixer in parts by weight, and mix for 30 minutes at 50°C at a speed of 1000 revolutions per minute. The mixed material Using an extruder to melt and extrude to granulate, the heating temperature is 200° C., and the extruding temperature of the head is 210° C. to obtain a composite material.

Embodiment 2

[0030] A preparation method of dopamine modified glass fiber-epoxy resin composite material, comprising the following steps:

[0031] Step 1. Prepare a dopamine hydrochloric acid solution with a concentration of 10 mg / mL, adjust the pH to 10, then soak the glass fibers in the dopamine hydrochloric acid solution, shake in the dark for 48 hours, then wash the glass fibers and dry them at 40°C; Sexual glass fiber; the mass volume ratio of the glass fiber to the dopamine hydrochloric acid solution glass fiber is 1:10;

[0032] Step 2. In parts by weight, add 100 parts of bisphenol A epoxy resin and 30 parts of dopamine-modified glass fiber into the mixer, and mix for 30 minutes at 60°C at a speed of 1200 revolutions per minute. The mixed material Using an extruder to melt and extrude to granulate, the heating temperature is 235° C., and the extruding temperature of the head is 220° C. to obtain a composite material.

Embodiment 3

[0034] A preparation method of dopamine modified glass fiber-epoxy resin composite material, comprising the following steps:

[0035] Step 1. Prepare a dopamine hydrochloric acid solution with a concentration of 8 mg / mL, adjust the pH to 9, then soak the glass fiber in the dopamine hydrochloric acid solution, shake it in the dark for 24 hours, then wash the glass fiber and dry it at 35°C to obtain dopamine-modified Sexual glass fiber; the mass volume ratio of the glass fiber to the dopamine hydrochloric acid solution glass fiber is 1:8;

[0036] Step 2: In parts by weight, add 80 parts of bisphenol A epoxy resin and 20 parts of dopamine-modified glass fiber into the mixer, mix at 55°C for 30 minutes at a speed of 1100 revolutions per minute, and the mixed material Using an extruder to melt and extrude to granulate, the heating temperature is 220° C., and the extruding temperature of the head is 215° C. to obtain a composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com