Minitype haptic rendering method based on active and passive devices

A passive device, tactile reproduction technology, applied in tactile transmission signal systems, instruments, computer parts, etc., can solve the problems of high energy density, small torque/volume ratio, and inability to accurately control magnetorheological dampers. Improve fidelity and immersion, large torque/volume ratio, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

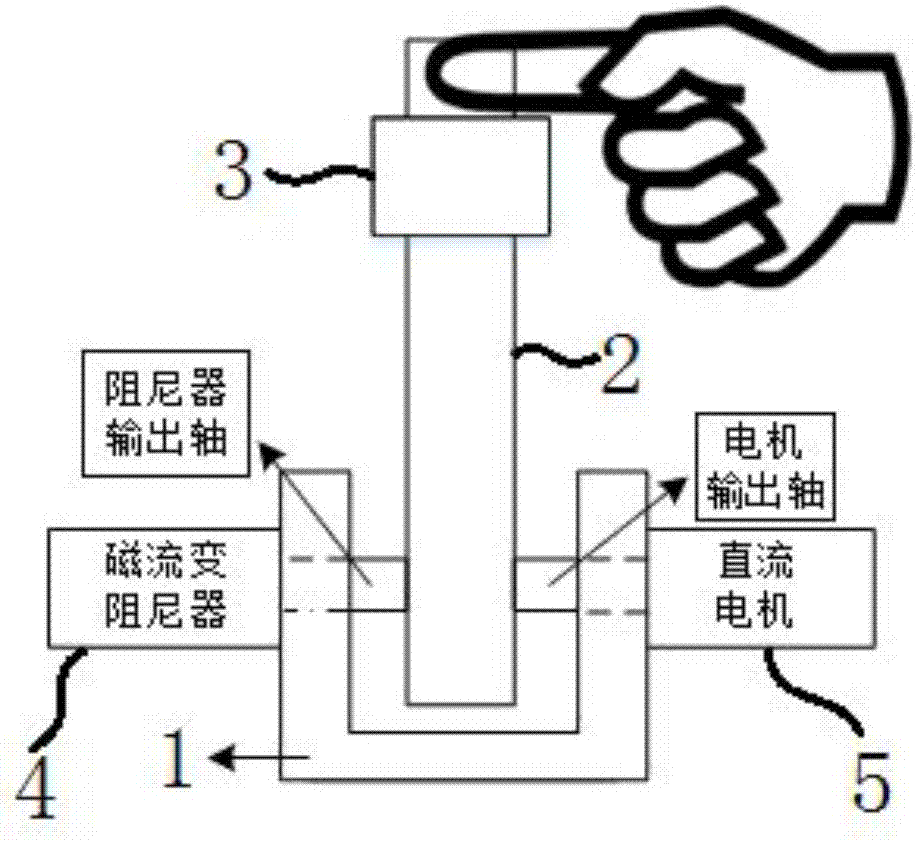

[0027] Such as figure 1 As shown, the force haptic reproduction device includes a bracket 1, an actuator fixed on both sides of the bracket 1, a force haptic transmission device 2 connected with the output shaft of the actuator, and a force / torque sensor 3 provided at the end of the force haptic transmission device 2, The force / torque sensor is used to measure the actual force / torque to form a feedback loop; the actuator is composed of a magnetorheological damper 4 and a DC motor 5, the output shaft of the DC motor and the output shaft of the magnetorheological damper Connected.

[0028] A high-precision and small-scale force tactile reproduction method based on active / passive devices, the specific steps are as follows:

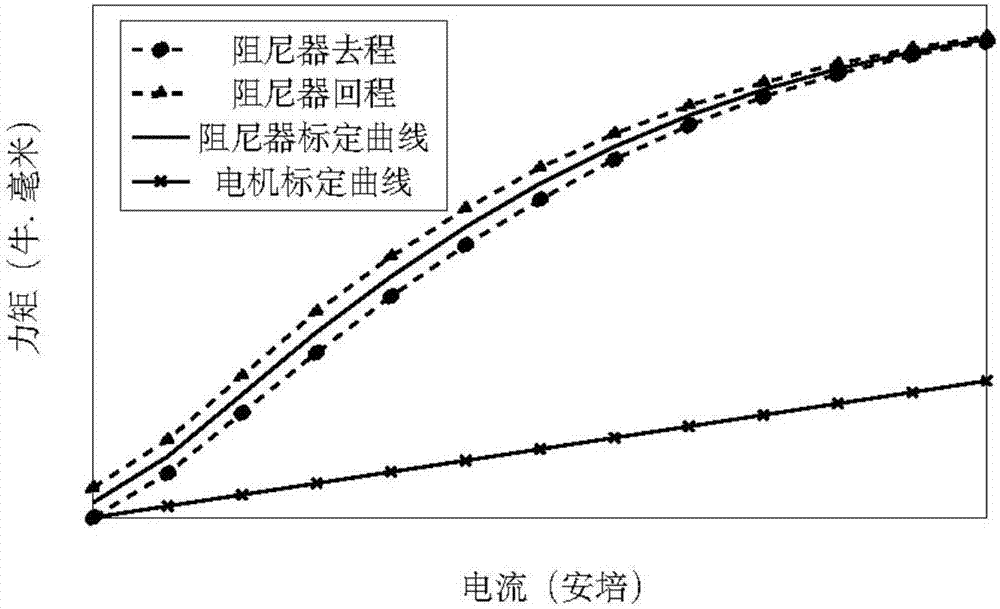

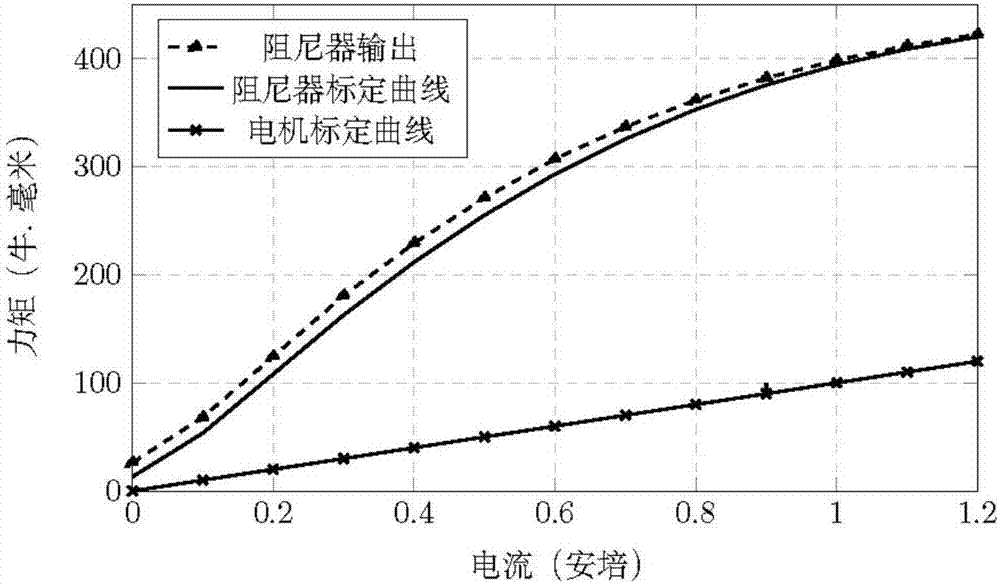

[0029] Step (A): Construct the above-mentioned equipment, calibrate the magnetorheological damper and DC motor, and obtain the relationship between the input current and output torque; the magnetorheological damper is made of ferromagnetic materials, One of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com