Water resistor capable of self-cyclically flowing and cooling for industry

A circulating flow, water resistance technology, applied in resistors, liquid resistors, resistor parts and other directions, can solve the problem of reducing the operating efficiency of high-voltage pulse devices, unable to meet the requirements of long-term, continuous work, and the increase of water resistance temperature resistance changes. Large and other problems, to achieve the effect of good heat dissipation, simple structure and improved heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

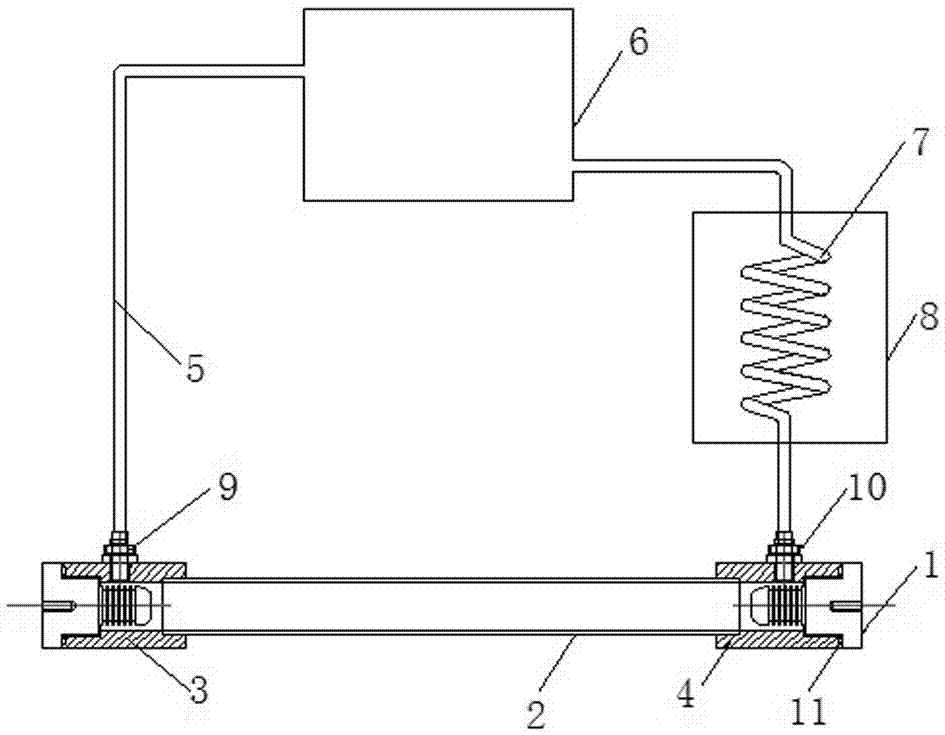

[0056] As shown in the figure, the water resistance of the present invention includes electrodes, water resistance main pipes, high-temperature connection end pipes, low-temperature connection end pipes, connection pipes, water tanks, spiral cooling pipes, and cooling devices arranged on the spiral cooling pipes. The electrodes are a group .

[0057] Electrodes, high-temperature connecting pipes, water resistor main pipes, low-temperature connecting pipes, and electrodes are connected in sequence to form a resistance main body, and the electrodes, high-temperature connecting pipes, water resistance main pipes, and low-temperature connecting pipes form a first accommodating chamber for distilled water . The main pipe of the water resistance and the high-temperature connection end pipe, and the main pipe of the water resistance and the low-temperature connection end pipe are connected by bonding. Sealing rings are respectively arranged between the high-temperature connection en...

Embodiment 2

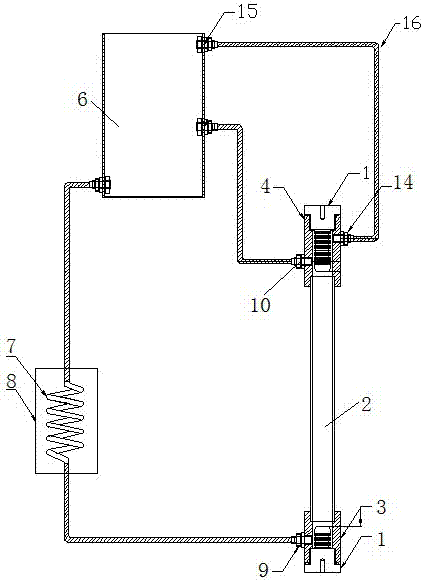

[0065] Such as figure 2 As shown, in this embodiment, the connecting pipes include a low-temperature water inlet pipe, a hot and cold water connecting pipe, a hot water compensation pipe, a first pipe joint, a low-temperature water inlet pipe, a cooling device, a cold and hot water connecting pipe, a water tank, and a hot water compensation pipe Connect with the second pipe joint in sequence. The main pipeline of the water resistor is arranged vertically, and the device also includes a pressure relief exhaust joint connected to the high-temperature connection end pipe, an exhaust connection pipe, a water vapor pipe outlet connection joint connected with the water tank, a pressure relief exhaust joint, an exhaust The connecting pipe and the outlet connector of the water vapor pipe are connected successively and the gas in the main pipeline of the water resistance can be discharged through the water tank through the pressure relief exhaust joint, the exhaust connecting pipe and...

Embodiment 3

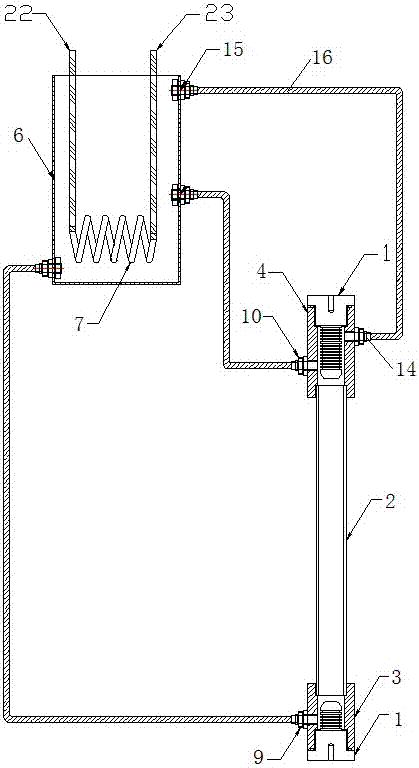

[0068] Such as image 3 , 4 As shown, in this embodiment, the cooling device is arranged in the water tank, the cooling pipe in the cooling device is cooled by cold air, and the two ends of the cooling pipe are respectively connected with the cold air inlet and the cold air outlet. The main pipe of the water resistance is arranged vertically, and the device also includes a pressure relief exhaust joint connected to the high-temperature connection end pipe, an exhaust connection pipe, a water vapor pipe outlet connection joint connected with the water tank, a pressure relief exhaust joint, an exhaust The connecting pipe and the outlet connector of the water vapor pipe are connected successively, and the gas in the main pipeline of the water resistance can be discharged through the water tank through the pressure relief exhaust joint, the exhaust connecting pipe, and the outlet connector of the water vapor pipe in sequence.

[0069] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com