Quantum dot, ink and quantum dot light emitting display device

A technology for quantum dot light-emitting and display devices, which is applied in the fields of electric solid-state devices, semiconductor devices, semiconductor/solid-state device manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

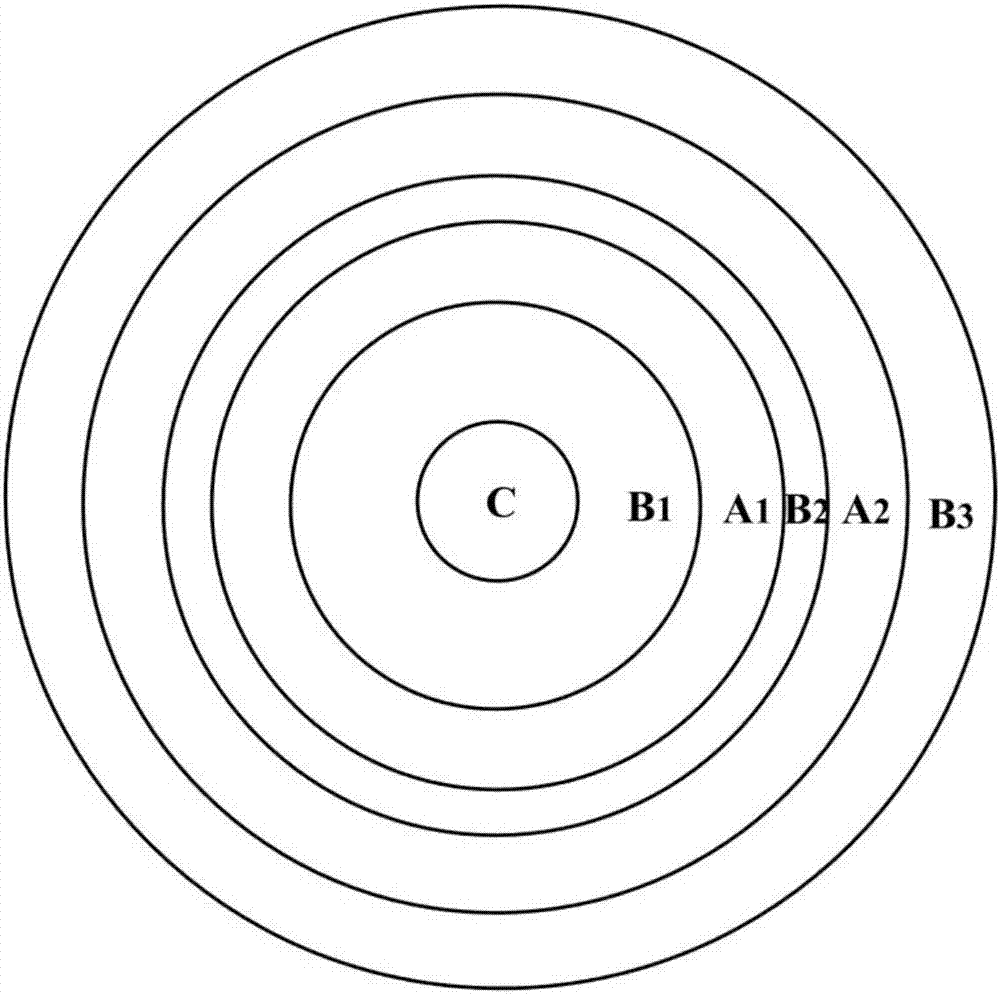

[0064] CdSe / ZnS / CdSe / ZnS (structure is C / B 1 / A 1 / B 2 ) synthesis of quantum dots:

[0065] Core C: Synthetic CdSe core with a particle size of about 3nm and a fluorescence emission peak of 580nm;

[0066] Shell B 1 : A monolayer of ZnS is coated on the CdSe core to obtain C / B 1 structured quantum dots;

[0067] Shell A 1 : Coating monolayer CdSe on C / B 1 structure of quantum dots, get C / B 1 / A 1 structured quantum dots;

[0068] Shell B 2 : Coating C / B with monolayer ZnS 1 / A 1 structure of quantum dots, the structure is C / B 1 / A 1 / B 2 quantum dots;

[0069] The quantum dot emits red light, the particle size is about 5nm, and the fluorescence peak is at 620nm.

Embodiment 2

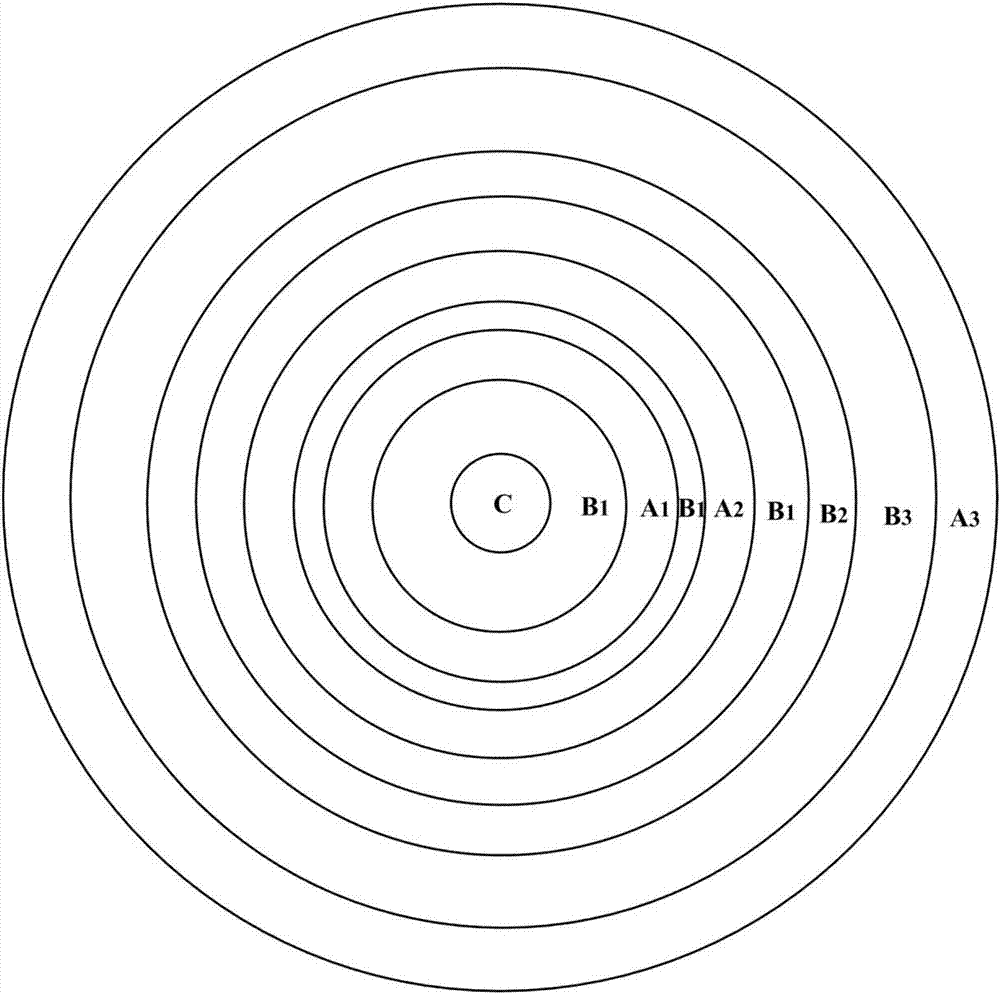

[0071] CdSe / CdS / ZnS / CdS / CdS / ZnS (structure is C / B 1 / B 2 / A 1 / B 1 / B 2 ) synthesis of quantum dots:

[0072] Core C: Synthetic CdSe core, the fluorescence emission peak is 580nm;

[0073] D. 1 Shell group (including B 1 / B 2 Shell layer): The monolayer CdS and ZnS are sequentially coated on the outer surface of the core C to obtain C / B 1 / B 2

[0074] structured quantum dots;

[0075] Shell A 1 : CdS monolayer coated on C / B 1 / B 2 The outer surface of the quantum dots of the structure, the obtained structure is C / B 1 / B 2 / A 1

[0076] structured quantum dots;

[0077] D. 2 Shell group (including B 1 / B 2 Shell layer): The monolayer CdS and ZnS are sequentially coated on the outer surface of the core C to obtain C / B 1 / B 2 / A 1 / B 1 / B 2 structured quantum dots;

[0078] The quantum dot emits red light with a fluorescence peak at 620nm.

Embodiment 3

[0080] Compared with Example 1, the manufacturing method of the quantum dots of this embodiment differs in that:

[0081] The position of the fluorescent peak of the synthesized CdSe core is at 520nm, in the second shell B 3 The outer layer is sequentially covered with the first shell layer and the second shell layer A 3 , B 4 、A 4 , B 5 、A 5 ,...,B 10 、A 10 , there are 20 shells in total, the total thickness of the shell is 20 monolayers, and the thickness of each layer is 1 monolayer, A 3 to A 10 Materials and Example 1 A 1 The materials are the same, the final luminous color is red light, and the particle size of the obtained quantum dots is about 20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com