Novel shrink packaging machine

A shrink packaging machine and packaging machine technology, applied in the direction of packaging, wrapping paper, wrapping paper shrinking, etc., can solve the problem that the first packaging sealing cover and the second packaging sealing cover cannot be installed at the same time, the packaging efficiency and packaging quality cannot be improved, and the packaging quality cannot be improved. Reduce manual labor intensity and other problems, achieve the effect of reducing manual labor intensity, simple structure, and realizing lifting automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

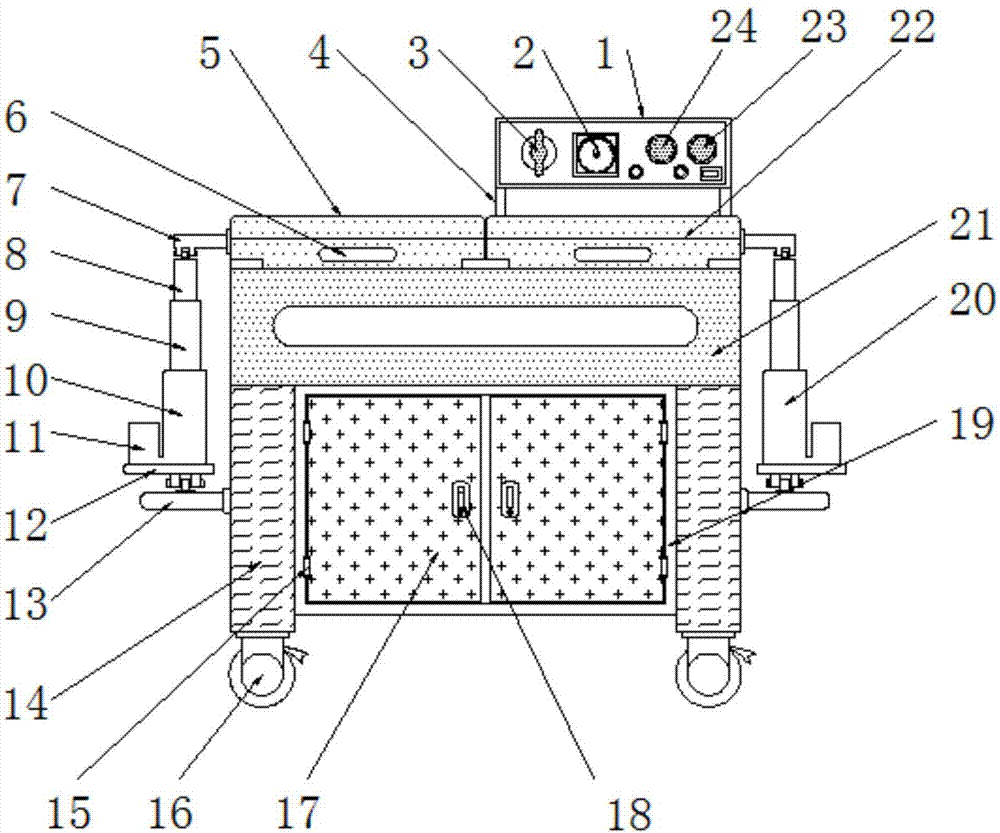

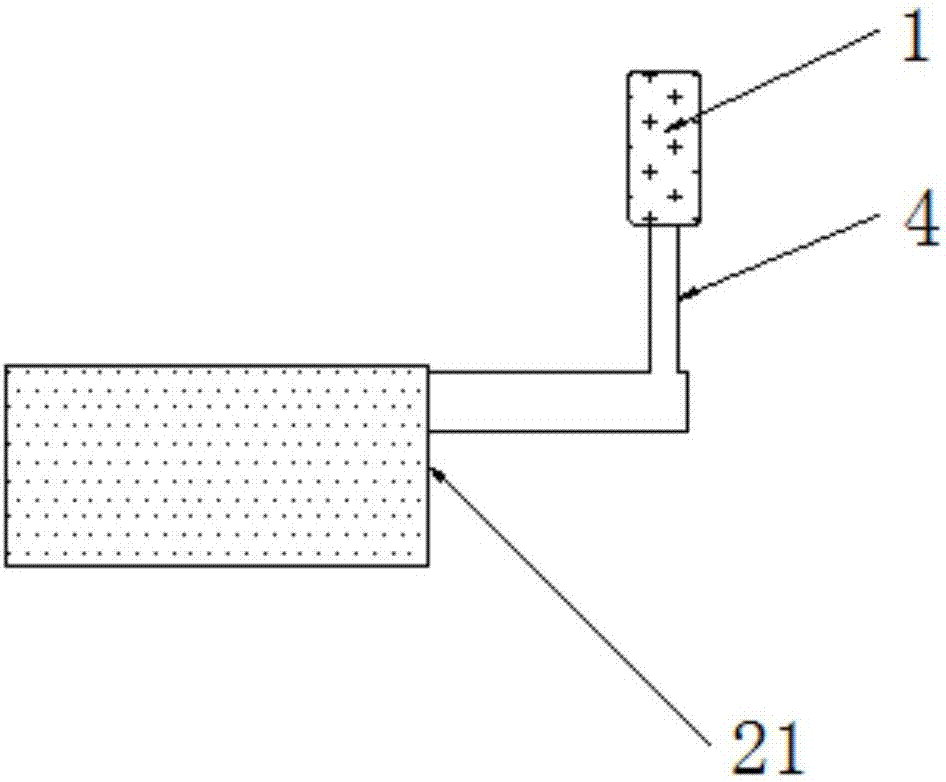

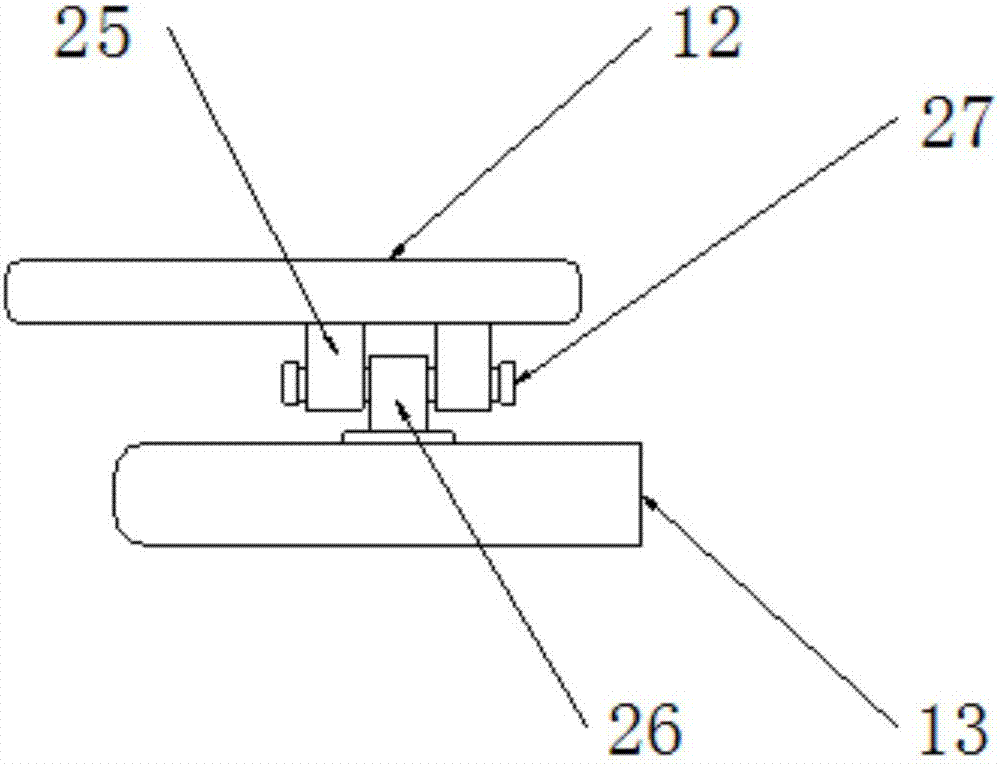

[0023] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a new shrink packaging machine, including a control panel 1, a vacuum pressure gauge 2, an emergency stop knob 3, a support frame 4, a first packaging sealing cover 5, a lifting handle 6, a fixed Plate 7, telescopic inner rod 8, telescopic outer rod 9, first electric telescopic rod 10, motor 11, Unicom base plate 12, support plate 13, support leg 14, rotary hinge 15, universal self-locking wheel 16, cabinet door 17, Cabinet handle 18, cabinet body 19, second electric telescopic rod 20, packaging machine body 21, second packaging sealing cover 22, vacuum adjustment knob 23, heating adjustment knob 24, Unicom bottom plate fixed shaft seat 25, support plate fixed shaft seat 26 , rotating shaft 27, fixed shaft seat 28 of telescopic inner rod, rotating shaft 29 and fixed plate fixed shaft seat 30, the top of universal self-locking wheel 16 is provided with supporting leg 14, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com