Inclined tower plate type coupled fluidized bed pyrolysis gasification device

A pyrolysis gasification, fluidized bed technology, applied in gasification process, granular/pulverized fuel gasification, production of combustible gas, etc., can solve problems such as low coal pyrolysis efficiency, achieve lower fixed investment, gasification High strength and good continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

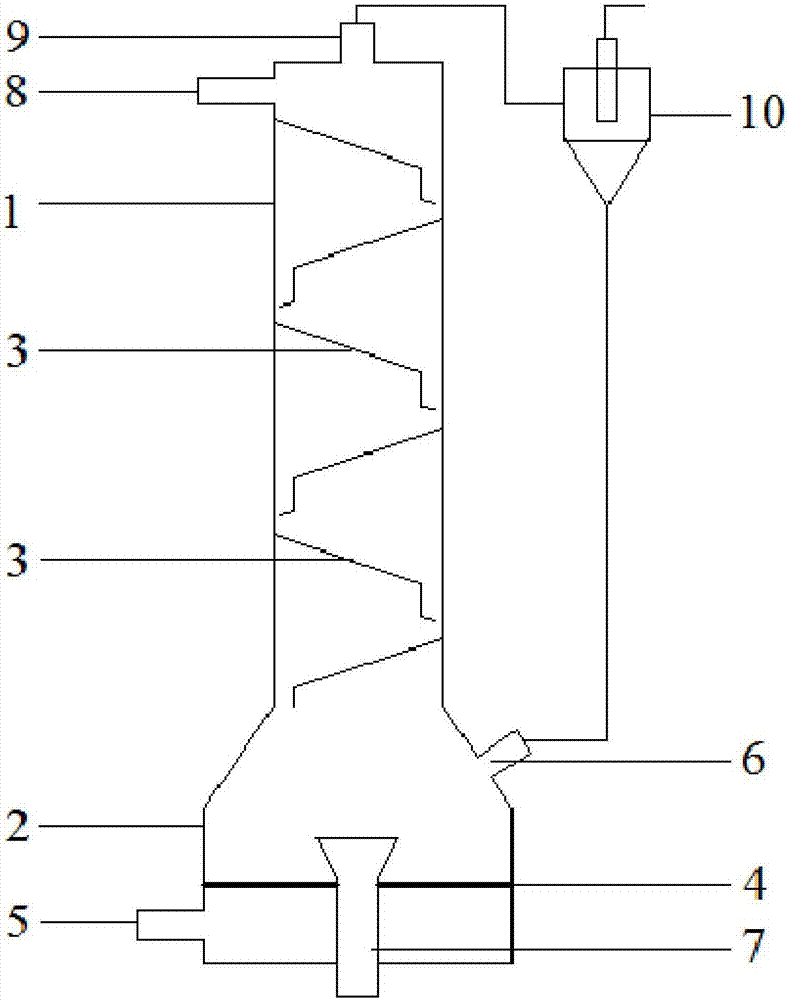

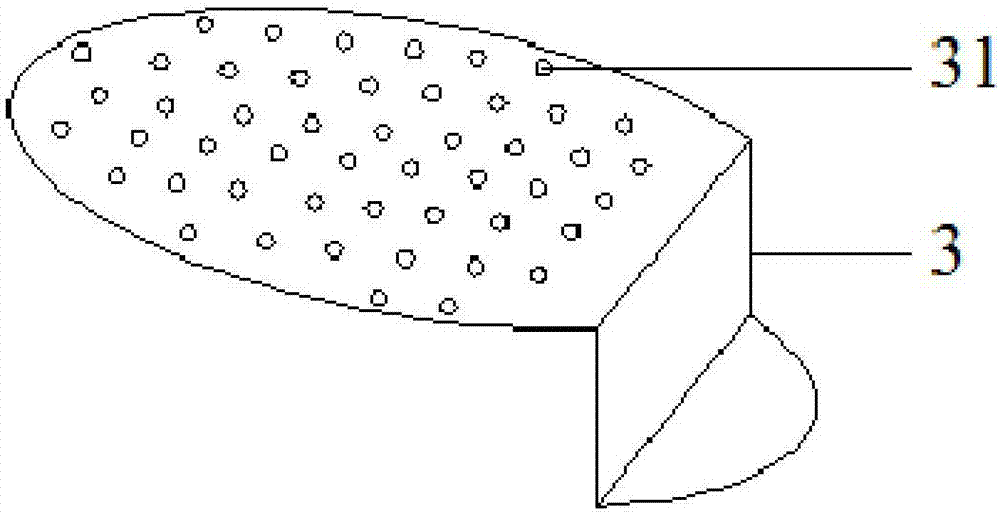

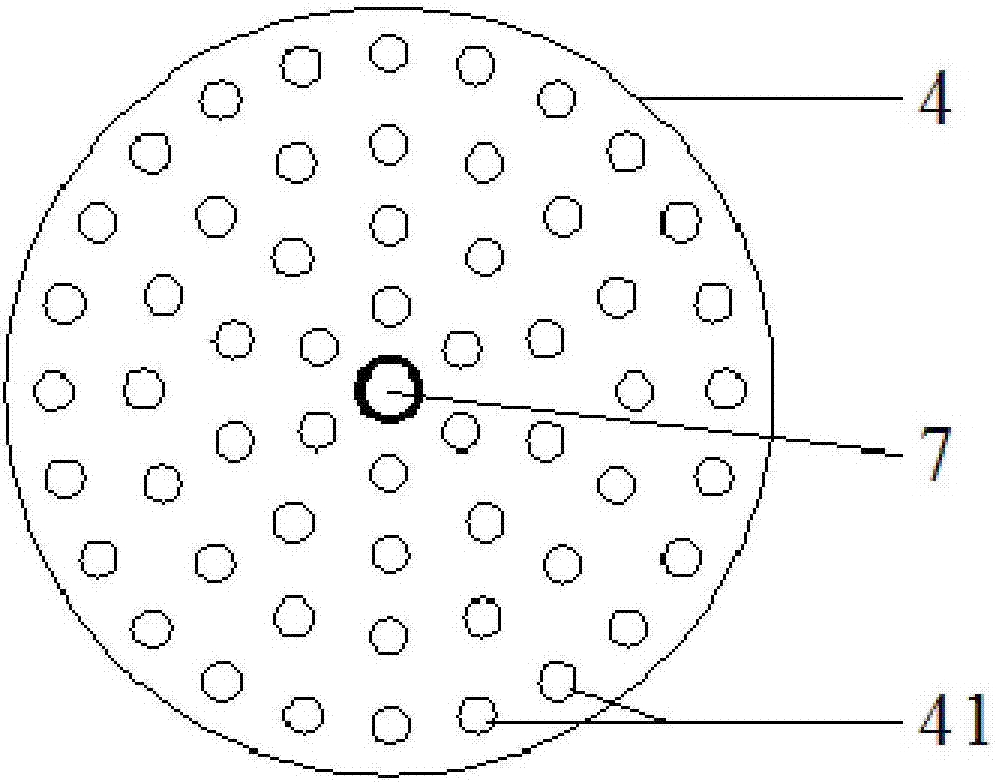

[0020] combine figure 1 , figure 2 and image 3 , an inclined tray type coupled fluidized bed pyrolysis gasification device, including a feed port 8, a reaction section shell 1, an expansion section shell 2 and a cyclone separator 10, the expansion section shell 2 is arranged on the reaction section shell 1, the feed inlet 8 is arranged on the upper side of the reaction section shell 1, and the top of the reaction section shell 1 is provided with an air outlet 9, which is connected to the cyclone separator 10, and the reaction section shell 1 is continuously Inclined trays 3 are arranged in a staggered manner. The inclined trays 3 include a body part and a bent part. Evenly distributed tray pores 31 are arranged on the surface of the body part. At the outlet, the material is transported from top to bottom to the shell 2 of the expansion section through the material outlets of each inclined tray 3 connected end to end and continuously staggered.

[0021] A gas distribution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com