A method for producing high-quality fuel oil from biomass

A biomass raw material and biomass technology, applied in the direction of fuel, liquid carbon-containing fuel, liquid hydrocarbon mixture preparation, etc., can solve the problems of low bio-oil yield, complicated process, and product yield less than 40%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] First weigh a certain amount of silica sol and add water to dilute to 5% aqueous sol solution, then add а-Al to the silica sol solution 2 o 3 Powder (diameter less than 1μm), ZrO 2 Powder (diameter less than 0.5 μm), then add appropriate amount of ethanol, put it into a ball mill for wet grinding. After wet milling for 24 hours, dry it. The powder passed through a 60-mesh sieve is calcined at 600°C for 2 hours, and then shaped as required. The molded body was sintered at 1200°C for 2 hours in the atmosphere, and then slowly cooled to room temperature with the furnace temperature. Two kinds of microwave additives TC-1 and TC-2 were prepared according to the different proportions of raw materials, and the composition of TC-1 was 65%Al 2 o 3 , 35%SiO2 2 , 5%ZrO 2 , TC-2 composition is 85% Al 2 o 3 , 10%SiO2 2 , 5%ZrO 2 .

Embodiment 2

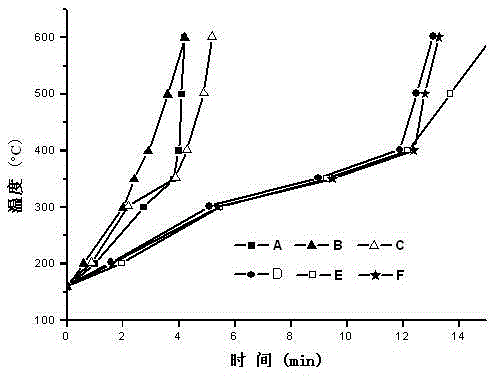

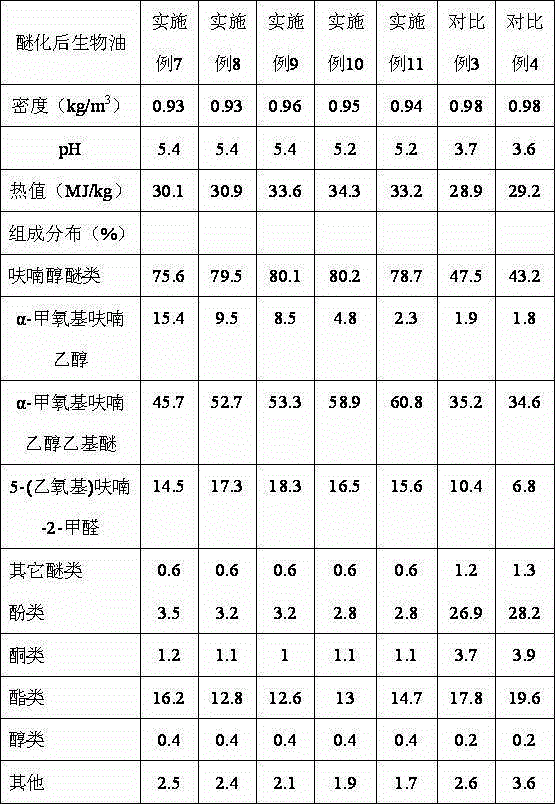

[0035] Mix 100g of wood chips (5mm), TC-1 (5mm) and 0.5% phosphoric acid solution according to the mass ratio of 1:0.1:0.1 and place them in a microwave pyrolysis reactor. First, microwave hydrolysis treatment at 120°C for 5 minutes, and then heat up to Dehydration is carried out at 140°C for 15 minutes, and the power density of the entire hydrolysis and dehydration process is 1×10 5 W / m 3 . Adjust Power 4×10 5 W / m 3 , and pyrolyze the above-mentioned dehydrated biomass at 350°C for 4 minutes, and then heat up to 500°C until no gas is generated. The generated pyrolysis volatiles are recovered by multi-stage condensation and subjected to solid-liquid separation to obtain 38g of bio-oil, of which the content of furans is 24.1%, and the content of sugars is 9.7%.

Embodiment 3

[0037] Mix 100g of wood chips (5mm), TC-2 (5mm) and 5% phosphoric acid solution according to the mass ratio of 1:1:0.3 and place them in a microwave pyrolysis reactor. First, microwave hydrolysis treatment at 80°C for 30 minutes, and then heat up to Dehydration is carried out at 160°C for 10 minutes, and the power density of the entire hydrolysis and dehydration process is 2×10 5 W / m 3 . Adjust power to 4×10 5 W / m 3 , and pyrolyze the above-mentioned dehydrated biomass at 400°C for 12 minutes, and then heat up to 600°C for pyrolysis until no gas is generated. The generated pyrolysis volatiles are recovered by multi-stage condensation and subjected to solid-liquid separation to obtain 58g of bio-oil, of which the content of furans is 59.4%, and the content of sugars is 19.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com