A Marshall compaction instrument

The technology of a compactor and a solid hammer is applied in the field of Marshall test equipment, which can solve the problems of user inconvenience, low efficiency, time-consuming and labor-intensive, etc., and achieve the effects of stable work, high work efficiency and smooth transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

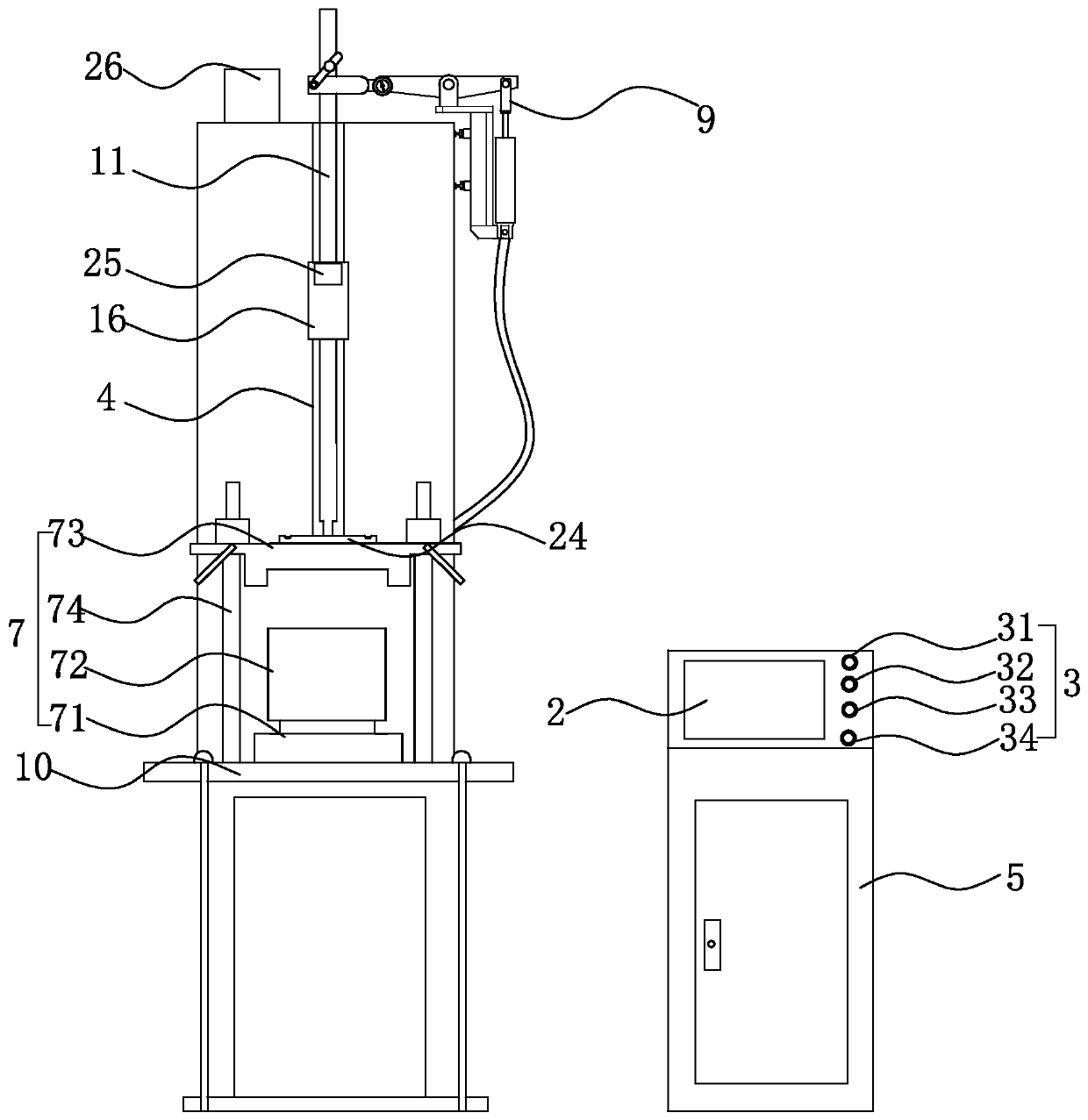

[0042] Embodiment: a kind of Marshall compaction instrument, with reference to figure 1 , including a body 1, a power distribution box 5 for controlling the work of the body 1 is provided on the side of the body 1.

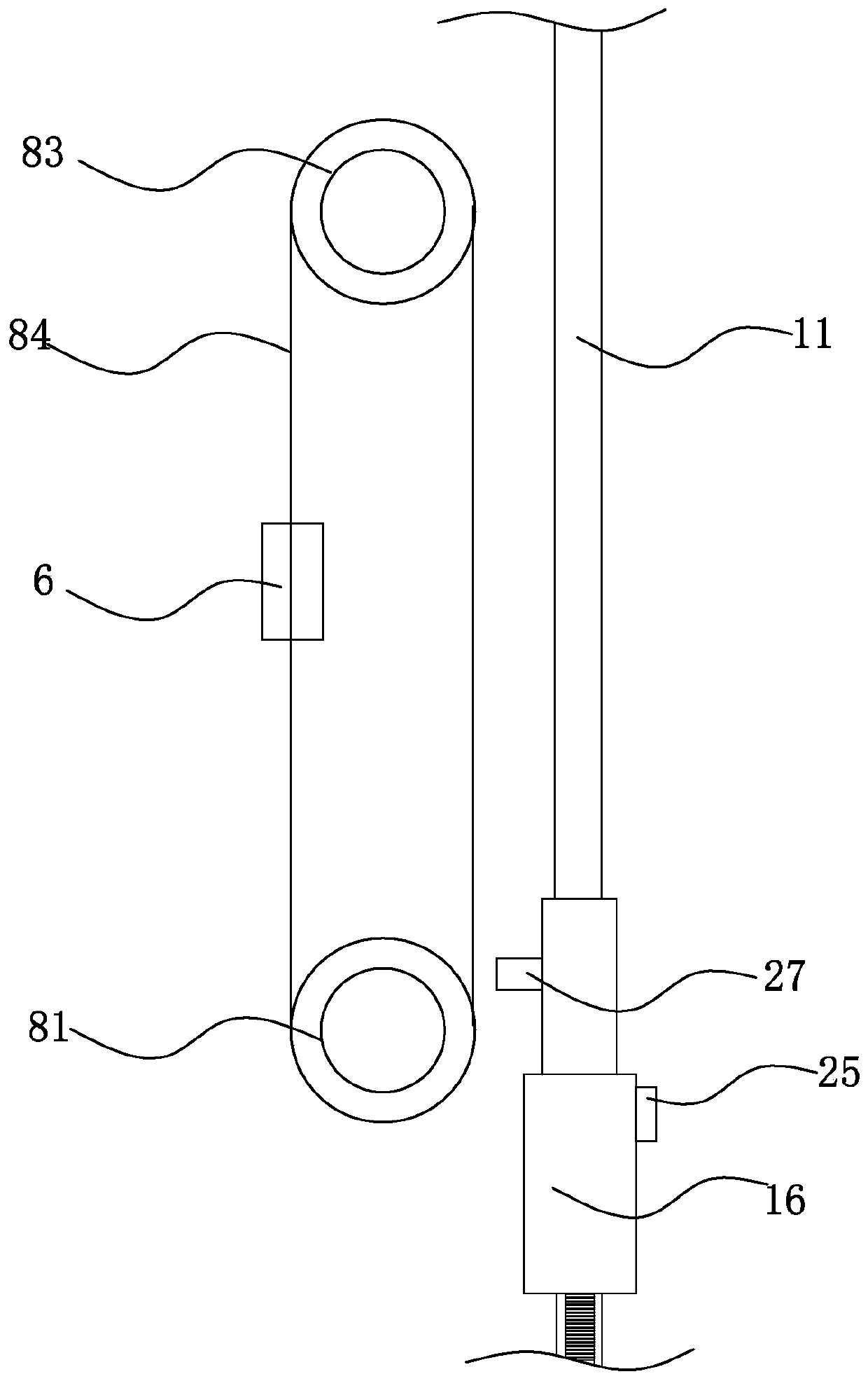

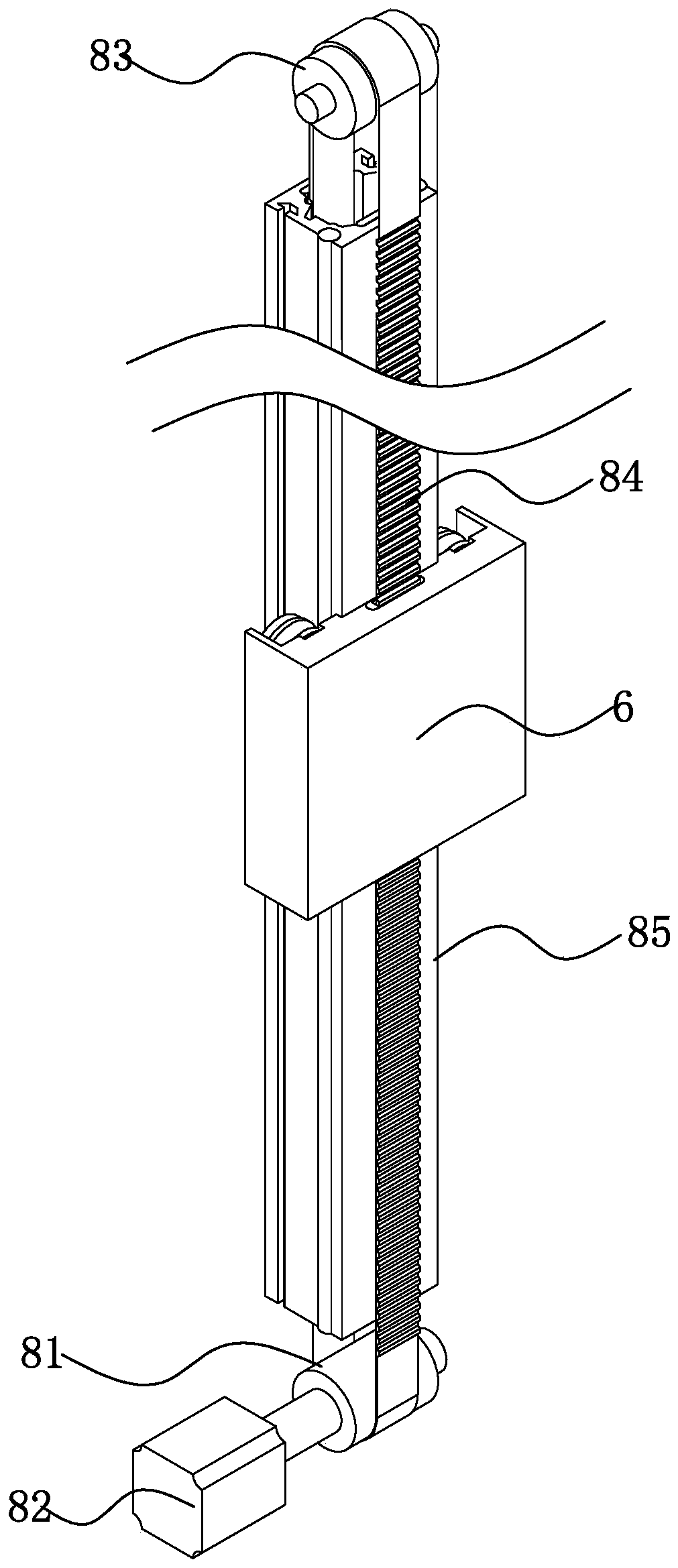

[0043] The body 1 is provided with a workbench 10, the workbench 10 is provided with a mold pressing device 7, the mold pressing device 7 is provided with a guide rod 11, the bottom of the guide rod 11 is provided with a compacting head 24, and the guide rod 11 is movable. There is a compaction hammer 16, on which there is a handle 27 and a counting sensor 25, each time the compaction hammer 16 strikes, the counting sensor 25 counts once and generates an induction signal, and the top of the guide rod 11 is provided with a compaction hammer The automatic lifting device 9 and the controller 26 are used to control the action of the automatic lifting device 9 for the compaction hammer in response to the induction signal of the counting sensor 25 .

[0044] The mold pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com