Method for determining structural support load of double key layers between coal seam group layers

A determination method and key layer technology are applied in the field of determination of the support load of the double key layer structure between the layers of the shallow buried coal seam group. The effect of mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

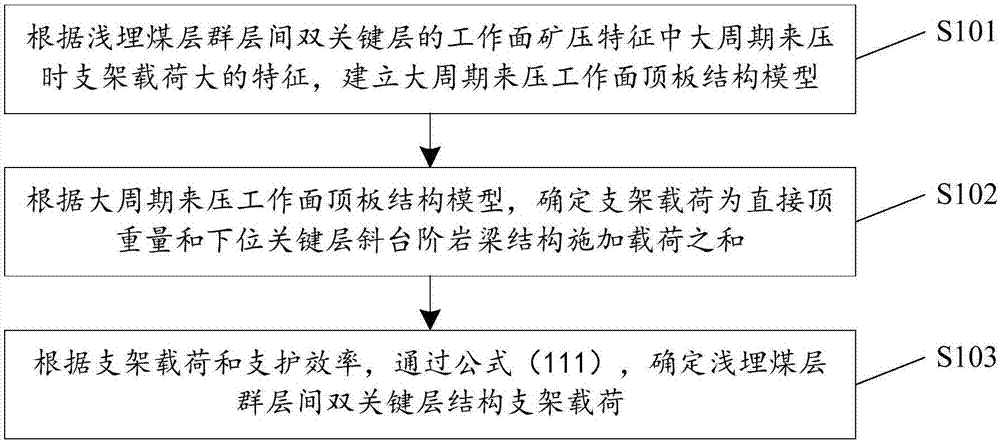

Method used

Image

Examples

example 1

[0050] Example 1: 22306 Working Face of Bulian Tower

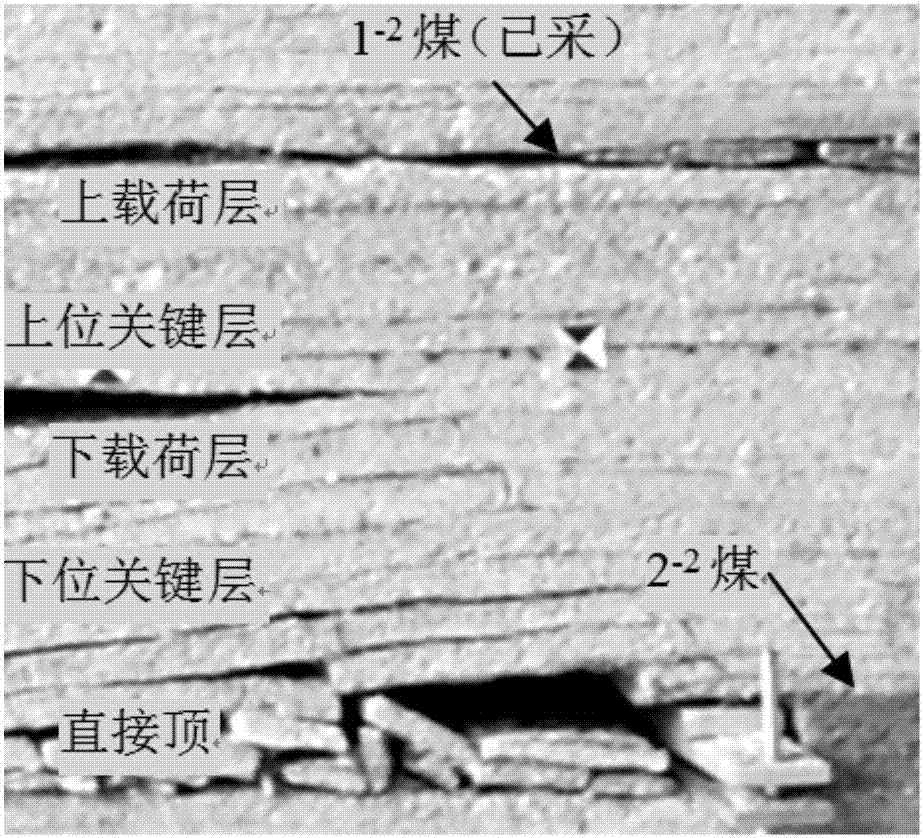

[0051] Bulian Tower 22306 Working Face Mining 2 -2 Coal, coal seam inclination angle 1-3°, buried depth 101-253m, mining height 6.8m, ZY18000 / 32 / 70D type two-column shield support is used for the working face. located in its upper part 1 -2 Coal working face 12307 has been mined into a goaf, with a mining height of 5.4m, a coal seam spacing of 28-35m, and a double key layer structure between layers. The 22306 working face has large and small cycles of pressure, the average step distance of the small period of pressure is 13m, and the average working resistance of the support during the pressure is 16900kN / frame; the average step distance of the large period of pressure is 37m, and the average working resistance of the support during the pressure is 19700kN / frame.

example 2

[0052] Example 2: Caragana tower N1200 working face

[0053] Mining at N1200 working face of Ningtiao Tower 2 -2 For coal, the dip angle of the coal seam is less than 1°, the buried depth is 67-151m, and the mining height is 5.87m. The working face adopts ZY12000 / 28 / 63D two-column shield support. located in its upper part 1 -2 The coal N1106 working face is mined into a goaf after mining, with a mining height of 1.72m, an average coal seam spacing of 39m, and a double key layer structure between layers. The N1200 working face has large and small cycles of pressure, the average step distance of the small cycle is 12m, and the maximum working resistance of the support during the pressure period is 12515kN / frame; the average step distance of the large cycle pressure is 24m, and the maximum working resistance of the support during the pressure period is 13872kN / frame.

[0054] Among them, the physical similarity simulation is as follows:

[0055] East Zone 1, North Wing, Ningti...

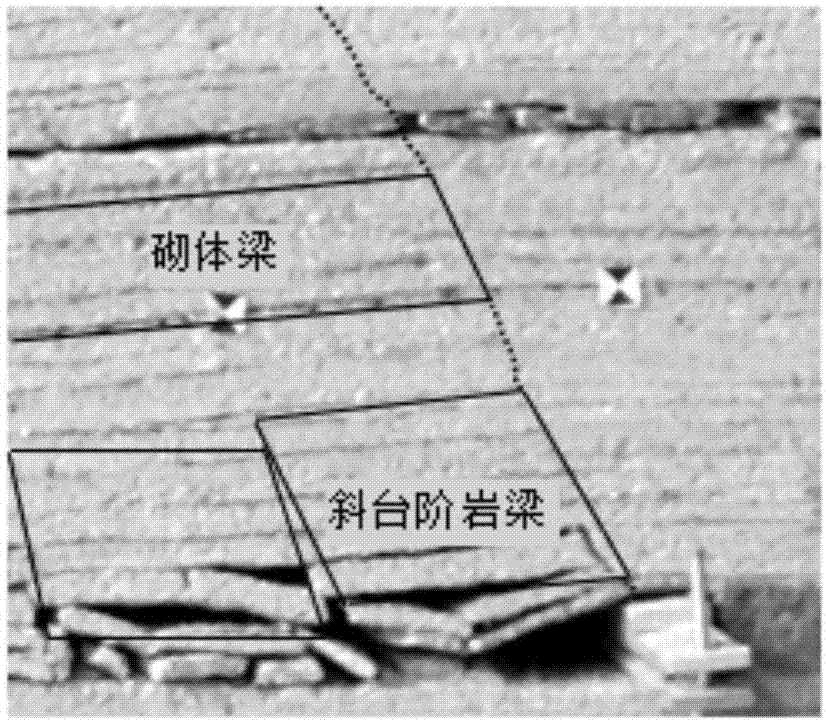

example

[0084] Mining at N1200 working face of Ningtiao Tower 2 -2 Coal, with an average mining height of 5.87m and an average buried depth of 102m, is located in the upper 1 -2 The coal N1106 working face has been mined into a goaf, with an average layer spacing of 39m, which belongs to the mining conditions of shallow buried coal seams with double key layer structure between layers. The calculation parameters are selected as follows: μ=0.9, b=1.75m; l k =5.0m; Σh=5.9m; ρ 1 g=22kN / m 3 ; h=12m; α=60°; L 1 =12m; m 2 =5.87m; h 1 =2.0m; ρg=25kN / m 3 ; L 2 =24m; h 2 =18m;K G = 0.4; h 3 = 0.8m.

[0085] According to formula (111):

[0086] P m =13810kN

[0087] According to the mining practice of the N1200 working face, the maximum working resistance of the hydraulic support on the working face is up to 13872kN / frame when it is pressed in a large cycle. The shielding support with a rated working resistance of 12000kN / frame cannot meet the requirement of compressive strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com