Laser wire stripping machine for transformer pins

A transformer and wire stripping machine technology, which is applied in the direction of transformer/coil connector, inductor/transformer/magnet manufacturing, line/collector components, etc., can solve the problems of high melting point of insulating layer and affect the stripping effect, and achieve improvement Efficiency, avoid inhalation hazards to health, avoid the effects of poor stripping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

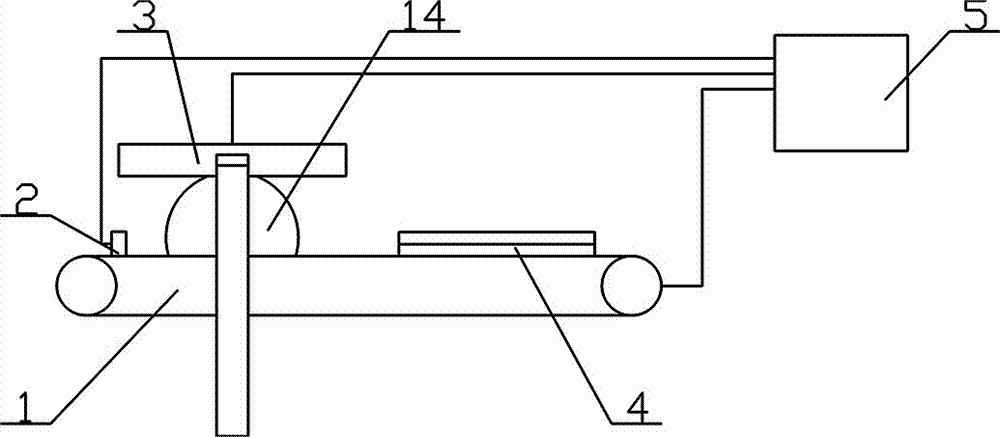

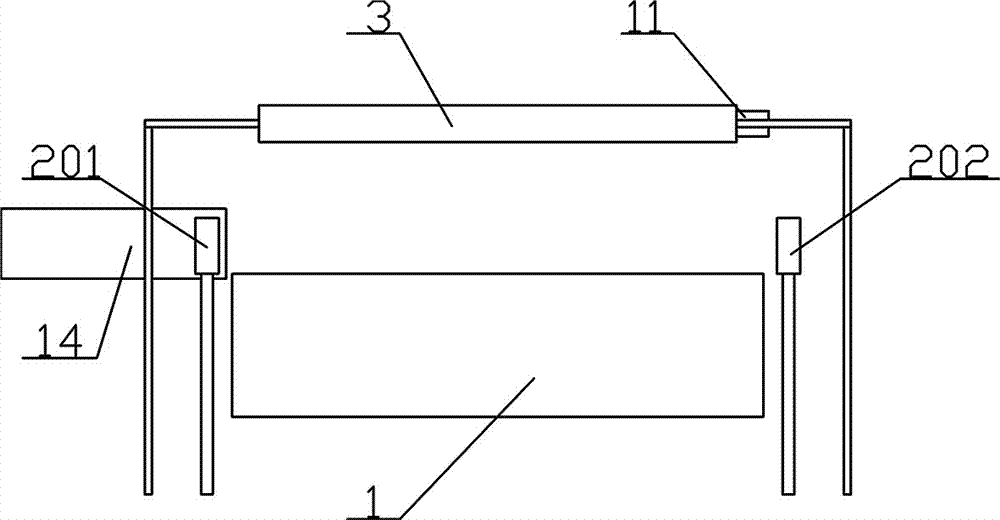

[0026] As shown in the figure, a laser wire stripping machine for transformer pins includes a transmission belt 1, a laser board 3 and a transformer tray 4, a laser board 3 is provided directly above one end of the transmission belt 1, and a laser generator is provided on the laser board 3. 13, the transformer tray 4 is placed on the conveyor belt 1.

[0027] The preferred solution is as figure 2 Among them, the transmission belt 1 is provided with an infrared sensor 2 on both sides of one end of the laser plate 3, and the infrared sensor 2 includes an infrared emitting device 201 and an infrared receiving device 202, and the infrared emitting device 201 and the infrared receiving device 202 are respectively arranged on Both sides of the conveyor belt 1.

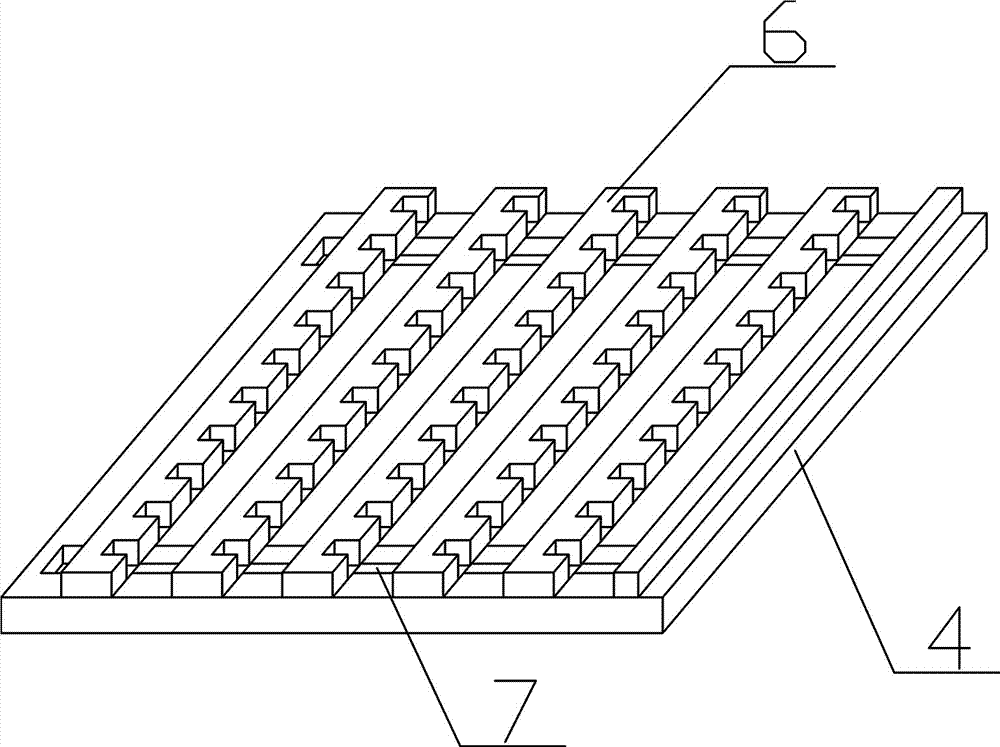

[0028] The preferred solution is as image 3 , Figure 5 Among them, the transformer tray 4 is provided with a plurality of transformer fixing bars 6, and each transformer fixing bar 6 is provided with a plurality of slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com