North large-scale breeding pig house

A pig house and partition wall technology, applied in animal houses, applications, animal husbandry, etc., can solve the problems of ground icing and ground freezing, and achieve the effect of increasing temperature, easy operation, and fine ventilation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

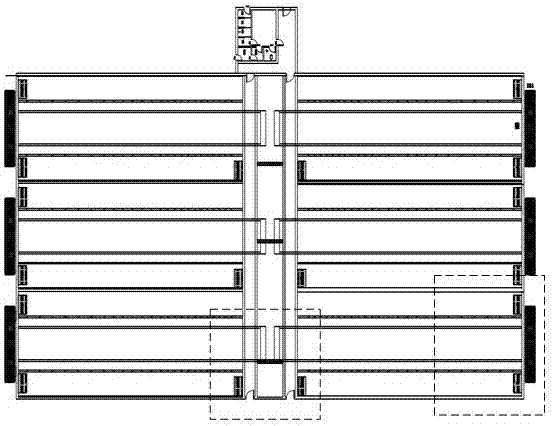

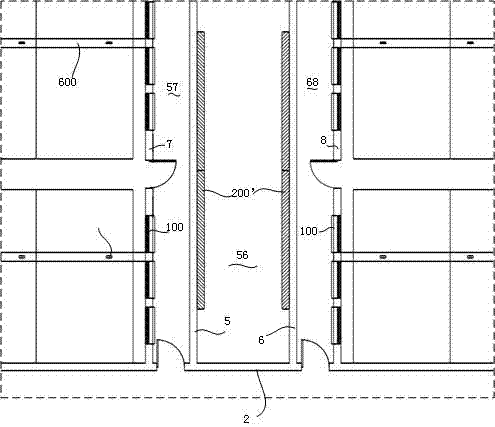

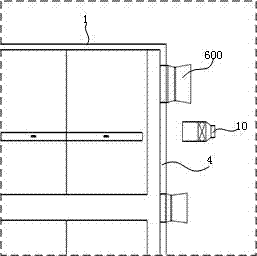

[0033] Embodiment 1: see attached Figure 1-6, 7-9, a large-scale breeding pig house in the north, including the first horizontal wall 1, the second horizontal wall 2, the first vertical wall 3, and the second vertical wall 4, located in the center of the house and parallel to the first The vertical wall 3 and the first partition wall 5 and the second partition wall 6 of the second vertical wall 4 are arranged on the first horizontal wall 1 , the second horizontal wall 2 , the first vertical wall 3 and the first partition wall 5 The first sloping roof 1235 is covered above the enclosed area, and the first sloping roof 1235 is covered above the area enclosed by the first horizontal wall 1, the second horizontal wall 2, the second vertical wall 4 and the second partition wall 6. A second sloping roof 1246 is provided, and the first partition wall 5 and the second partition wall 6 extend upwards over the first sloping roof 1235 and the second sloping roof 1246 to form a first gab...

Embodiment 2

[0036] Embodiment 2, see attached Figure 1-6 , 10-11, others are the same as in Example 1, the difference is that when the average air temperature is in the range of 0 degrees Celsius to 10 degrees Celsius, the pig house ventilation is required to increase, so the first ventilation window 100 and the fourth ventilation window 400 are closed, The second ventilation window 200 and the third ventilation window 300 are opened, and the eaves ventilation window 500 is also opened at the same time. The water curtain window 200' does not need to be activated, but the heating device 9 is turned on. The heating device is water heating or Oil and natural gas heating.

[0037] Not only is a part of the fresh air preheated in three stages as in Example 1, and then it is evenly and gently blown from the air outlet 201 to the inside and outside of the pig house, because the ventilation window 500 under the eaves is opened, another part of the fresh air enters the ceiling from the ventilatio...

Embodiment 3

[0038] Embodiment 3, see attached Figure 1-6 , 12-13, others are the same as embodiment 2, and the difference is that when the average temperature is between 10 degrees Celsius and 26 degrees Celsius, the ventilation volume of the piggery is required to be further increased, so the first ventilation window 100 is closed, and the second ventilation window is closed. The window 200, the third ventilation window 300, the fourth ventilation window 400 and the eaves ventilation window 500 are all open, the water curtain window 200' is not activated, and the heating device 9 is closed.

[0039] In addition to the fresh air entry mode in Embodiment 2, the fresh air outside the house enters the middle corridor from the fourth ventilation window 400, and then merges with the other two parts of the fresh air, and blows evenly and softly into the pig house from the air supply port 201. The turbid air in the lower layer of the house enters the turbid air trench 700 and the outer trench 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com