Preparation device and preparation method of cyanohydrin

A preparation device and technology for cyanohydrin, applied in the field of liquid-liquid phase reaction, can solve the problems of difficult to control the radial temperature of a tubular reactor, difficult continuous production, uneven radial concentration, etc., and achieve accurate reaction residence time , The effect of increasing the radial temperature uniformity and controlling the reaction residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

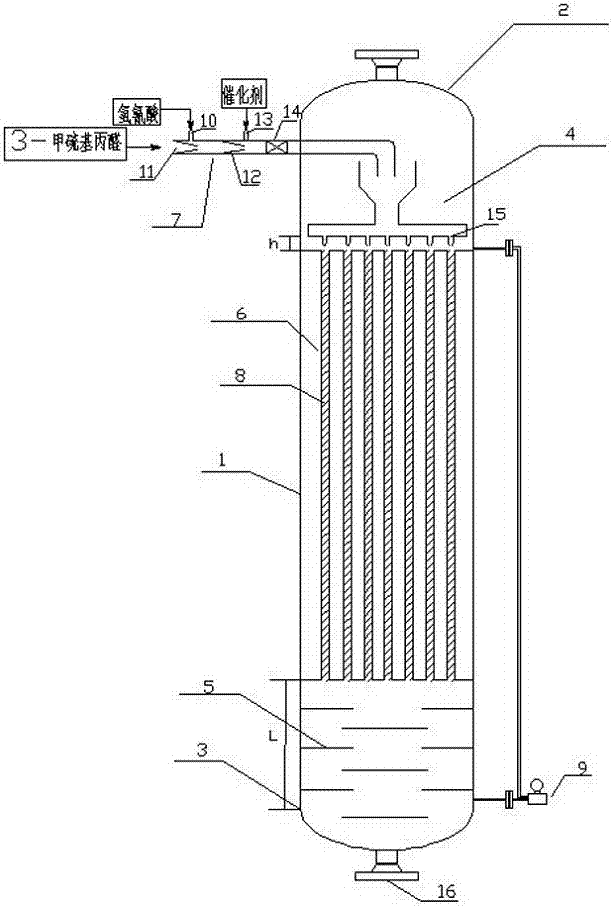

[0056] A kind of preparation device of embodiment 1 cyanohydrin

[0057] It mainly includes shell 1, upper head 2, lower head 3, liquid distributor 4, baffle 5, reaction tube 6, feeding device 7, packing 8, liquid level gauge 9;

[0058] The two ends of the housing 1 are respectively connected to the upper head 2 and the lower head 3, the housing 1 is provided with reaction tubes 6, the number of which is used for the reaction, the housing 1 is provided with a baffle, and the reaction The tube 6 is filled with filler 8; the liquid distributor 4 is located at the upper head 2 close to the shell 1; the baffle 5 is arranged inside the lower head 3.

[0059] The liquid distributor 4 includes a distribution hole 15; the hole flow coefficient K value of the distribution hole 15 is 0.95;

[0060] The distance between the distribution hole interface of the liquid distributor 4 and the uppermost end of the housing 1 is h, and h is 250 mm.

[0061] Described feeding device 7 comprises...

Embodiment 2

[0070] Embodiment 2 A kind of preparation device of cyanohydrin

[0071] It mainly includes shell 1, upper head 2, lower head 3, liquid distributor 4, baffle 5, reaction tube 6, feeding device 7, packing 8, liquid level gauge 9;

[0072] The two ends of the housing 1 are respectively connected to the upper head 2 and the lower head 3, the housing 1 is provided with reaction tubes 6, the number of which is used for the reaction, the housing 1 is provided with a baffle, and the reaction The tube 6 is filled with filler 8; the liquid distributor 4 is located at the upper head 2 close to the shell 1; the baffle 5 is arranged inside the lower head 3.

[0073] The liquid distributor 4 includes a distribution hole 15; the hole flow coefficient K value of the distribution hole 15 is 0.8;

[0074] The distance between the distribution hole interface of the liquid distributor 4 and the uppermost end of the housing 1 is h, and h is 500mm.

[0075] Described feeding device 7 comprises h...

Embodiment 3

[0085] Embodiment 3 A kind of preparation method of cyanohydrin

[0086] Include the following steps:

[0087] (1) Feed

[0088] 3-Methylthiopropanal is fed by the first Venturi nozzle 11, and the feed rate is 1040kg / h, and the nozzle discharge speed is at 20m / s;

[0089] Hydrocyanic acid is fed by hydrocyanic acid feed inlet 10, and feed rate is 270kg / h, enters the second Venturi nozzle 12 together with 3-methylthiopropanal, and the discharge speed of the second Venturi nozzle 12 is 30m / s;

[0090] Adopt 1% aqueous ammonia solution to be catalyzer, enter pipeline by catalyst inlet 13, feed rate is 15.4kg / h; Enter static mixer 14 and mix with 3-methylthiopropionaldehyde and prussic acid, mixing time is 1s.

[0091] (2) into the reactor

[0092] The mixed material is discharged into the liquid distributor 4 by the static mixer 14, and the residence time in the pipeline is 5s; the pipeline is the pipeline between the outlet section of the static mixer and the outlet secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com