High-strength inflation-free solid tire and production method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

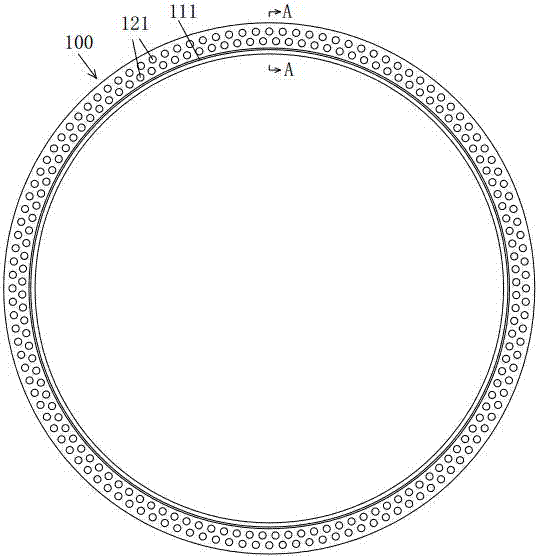

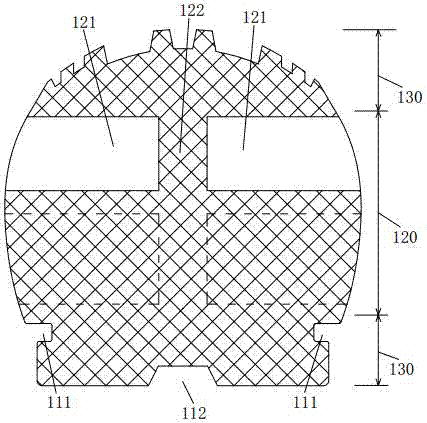

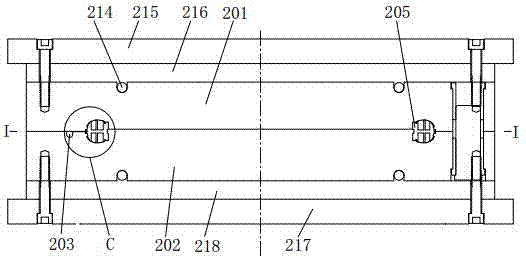

[0027] refer to figure 1 and figure 2

[0028] A high-strength non-pneumatic solid tire, comprising an annular tire body 100 integrally formed by an anti-separation layer 110, a shock-absorbing layer 120 and an anti-skid layer 130 from the inner ring to the outer ring, and the annular tire body is located on the shock-absorbing layer Axial shock-absorbing blind holes 121 are arranged at intervals along the annular direction of the annular tire body, and annular grooves 111 for fitting with the rim of the steel rim are respectively arranged on both sides of the anti-skid layer. , the inner side of the anti-skid layer is provided with an annular positioning groove 112 for matching with the annular positioning p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com