A kind of composite damping material and its application in isolation bearing

A technology of composite damping materials and bearings, which is applied in the direction of shockproof, bridges, bridge parts, etc., can solve problems such as occupational health risks and environmental pollution, and achieve the effects of uncomplicated formula, reduced production cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

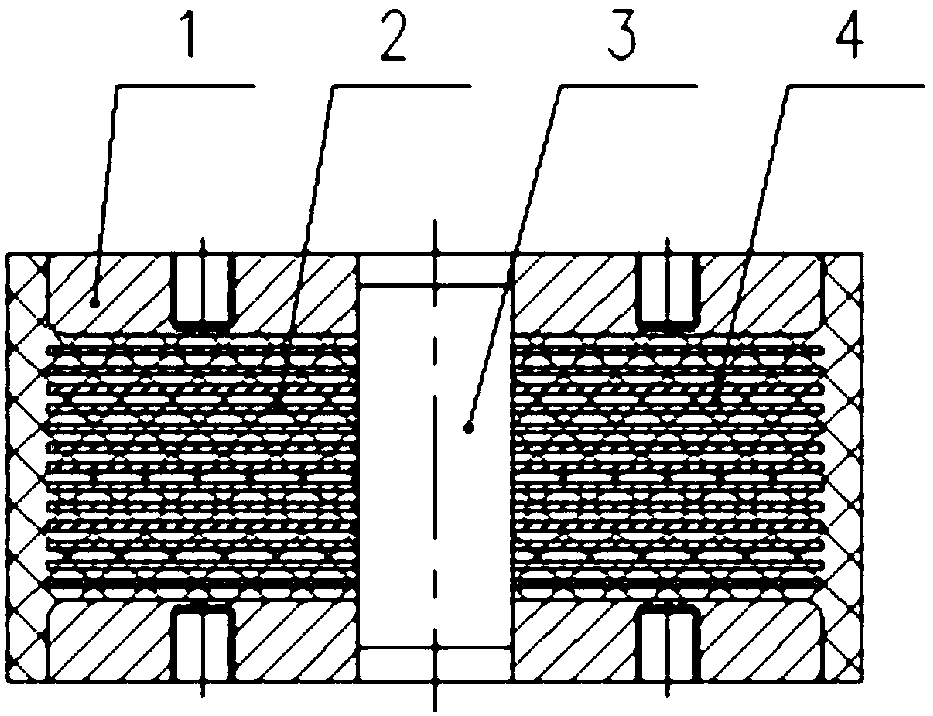

[0038] The specific preparation process of the composite damping material and shock-isolation rubber bearing in this example is as follows

[0039] 1) Preparation of composite damping material: Weigh 100 parts of cross-linked rubber, 150 parts of aluminum powder, and 80 parts of processing aids (processing aids include: 100 parts of raw rubber, 150 parts of aluminum powder, 5 parts of zinc oxide , 2 parts of stearic acid, 30 parts of operating oil, 5 parts of anti-aging agent, 3 parts of sulfur, 30 parts of carbon black, 5 parts of dispersant), according to the conventional process of rubber product production: in an open mill or an internal mixer The above materials are kneaded to make them uniformly dispersed to obtain the mixed rubber, which is the composite damping material.

[0040] 2) Preparation of the vibration-isolation rubber bearing: Fill the above-mentioned composite damping material into the forming mold, put it on a press and press it to form a core rod of the co...

Embodiment 2

[0042] The specific preparation process of the composite damping material and shock-isolation rubber bearing in this example is as follows

[0043] 1) Preparation of composite damping material: Weigh 100 parts of cross-linked rubber, 200 parts of aluminum powder, and 50 parts of processing aid (processing aid includes: 100 parts of raw rubber, 150 parts of aluminum powder, 5 parts of zinc oxide , 2 parts of stearic acid, 30 parts of operating oil, 5 parts of anti-aging agent, 3 parts of sulfur, 30 parts of carbon black, 5 parts of dispersant), according to the conventional process of rubber product production: in an open mill or an internal mixer The above materials are kneaded to make them uniformly dispersed to obtain the mixed rubber, which is the composite damping material.

[0044] 2) Preparation of the vibration-isolation rubber bearing: Fill the above-mentioned composite damping material into the forming mold, put it on a press and press it to form a core rod of the com...

Embodiment 3

[0046] The specific preparation process of the composite damping material and shock-isolation rubber bearing in this example is as follows

[0047] 1) Preparation of composite damping material: Weigh 100 parts of non-crosslinked rubber, 30 parts of iron powder, and 10 parts of processing aid (processing aid includes: 100 parts of raw rubber, 150 parts of aluminum powder, 5 parts of zinc oxide 2 parts, 2 parts of stearic acid, 30 parts of operating oil, 5 parts of anti-aging agent, 3 parts of sulfur, 30 parts of carbon black, 5 parts of dispersant), according to the conventional production process of rubber products: in open mill or internal mixer Mix the above materials in the medium to make them uniformly dispersed to obtain the mixed rubber, which is the composite damping material.

[0048] 2) Preparation of shock-isolation rubber bearing: Fill the above-mentioned composite damping material, together with the steel plate and rubber of the vulcanized bearing, into the forming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com