Manufacturing machine for non-woven fabric

A technology for manufacturing machines and non-woven fabrics, applied in the field of non-woven fabrics manufacturing machines, can solve the problems of low tensile strength in warp and weft directions, decrease in tensile strength, and increase in weight, so as to increase interlayer shear force, tensile strength, etc. The effect of strength increase and density increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment, the present invention is described in detail:

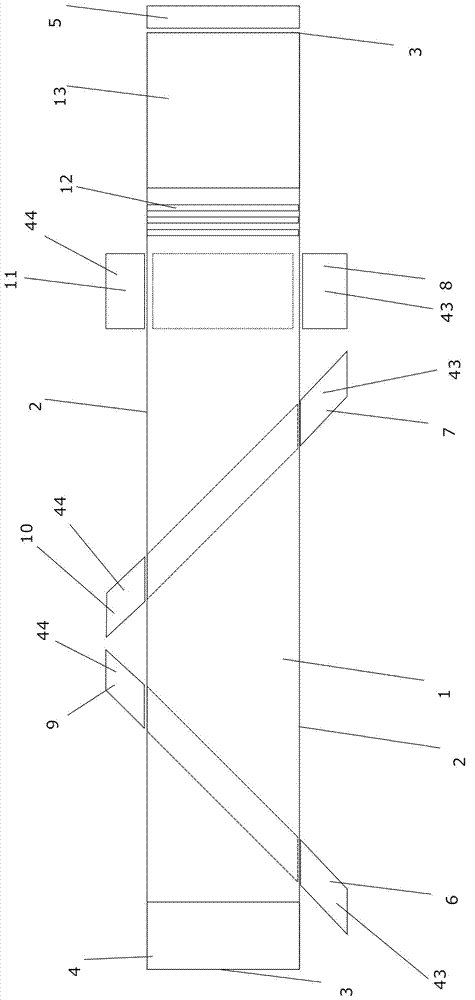

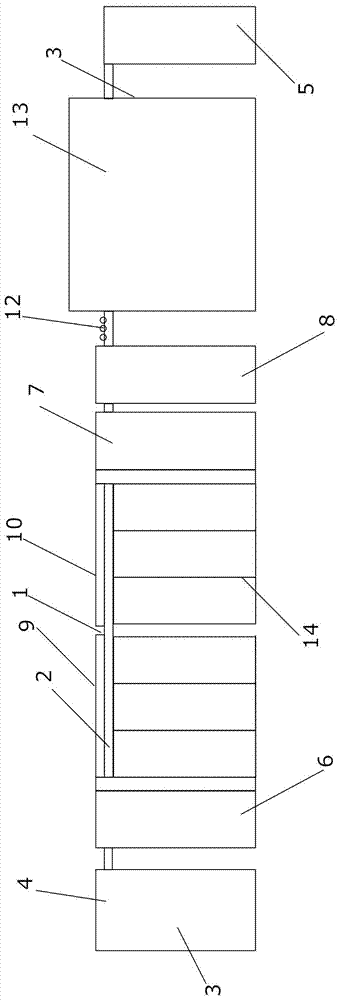

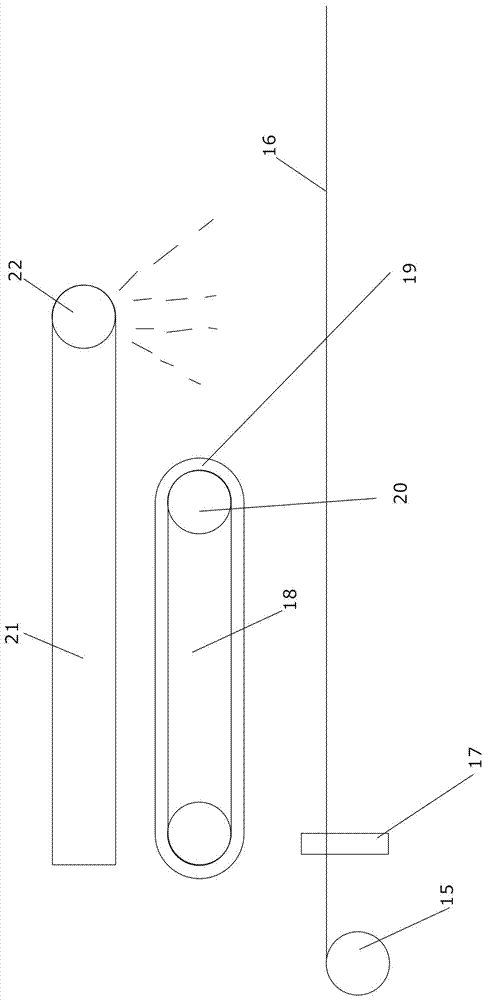

[0030] like Figure 1 to Figure 8 Shown: the embodiment of the present invention is a non-woven fabric manufacturing machine and its manufacturing method and principle, the non-woven fabric machine is mainly used for manufacturing filament bundle non-woven fabric, and the non-woven fabric is used for composite materials Reinforcing material in the material, the reinforcing material includes raw material using filament tow, including carbon fiber filament tow, aramid tow, glass fiber filament tow non-woven fabric, and can also be used to manufacture reinforcement materials that are not used in composite materials. The general-purpose non-woven fabric, the general-purpose non-woven fabric, is made of filament bundles as raw materials, chopped strands, and mixed strands.

[0031] The non-woven fabric manufacturing machine is provided with a rectangular platform surface 1, with parallel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com