Adaptive Torque Balance Differential Pressure Drill

A torque-balanced, differential-pressure technology, applied in drill bits, drilling tools, earth-moving drilling, etc., can solve the problems of prolonging the well construction period, improving the drilling efficiency of the drill bit, and fluctuating the torque of the drill bit, so as to avoid torsional impact. Vibration, reduction of non-productive time, principle and effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

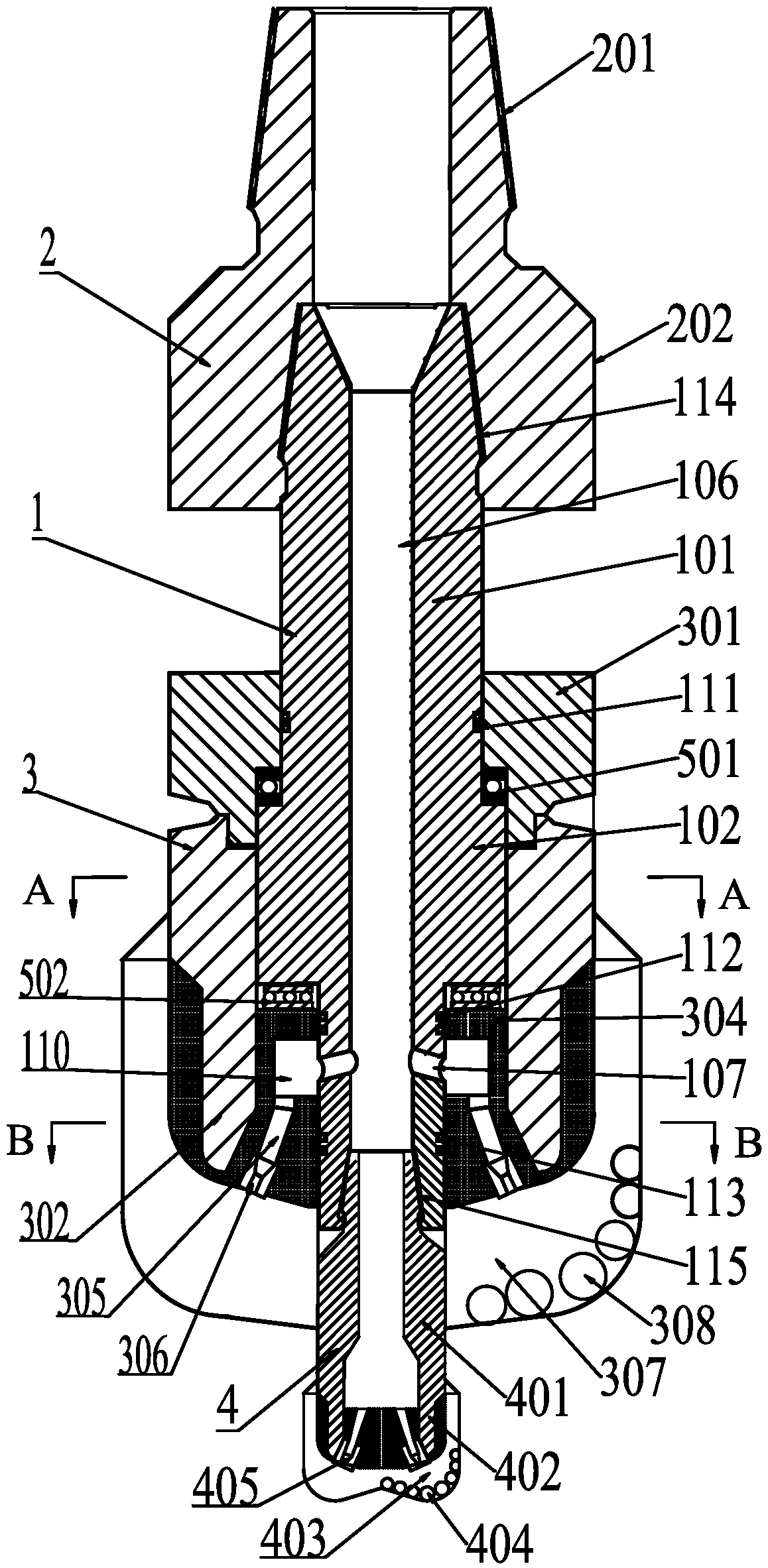

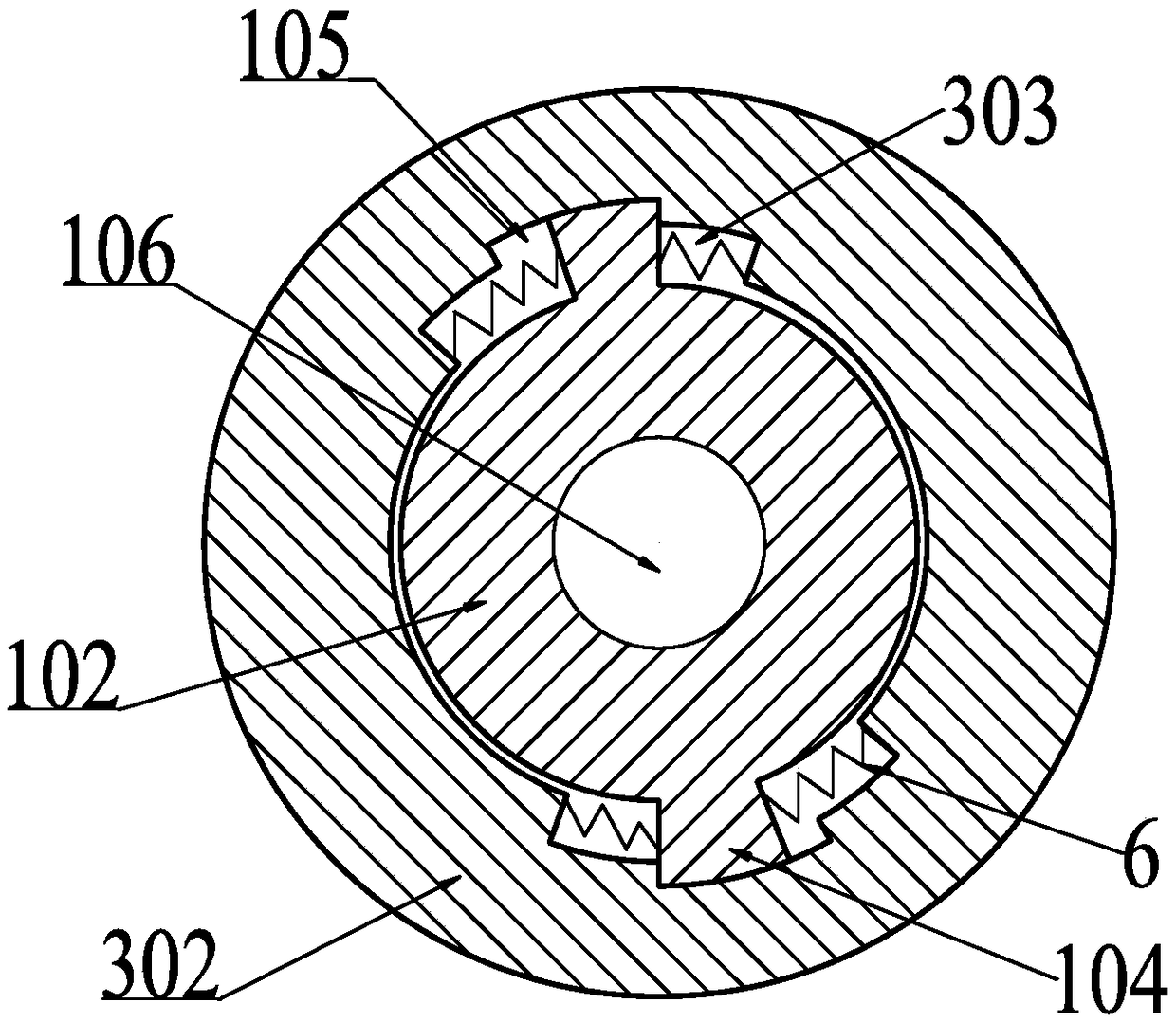

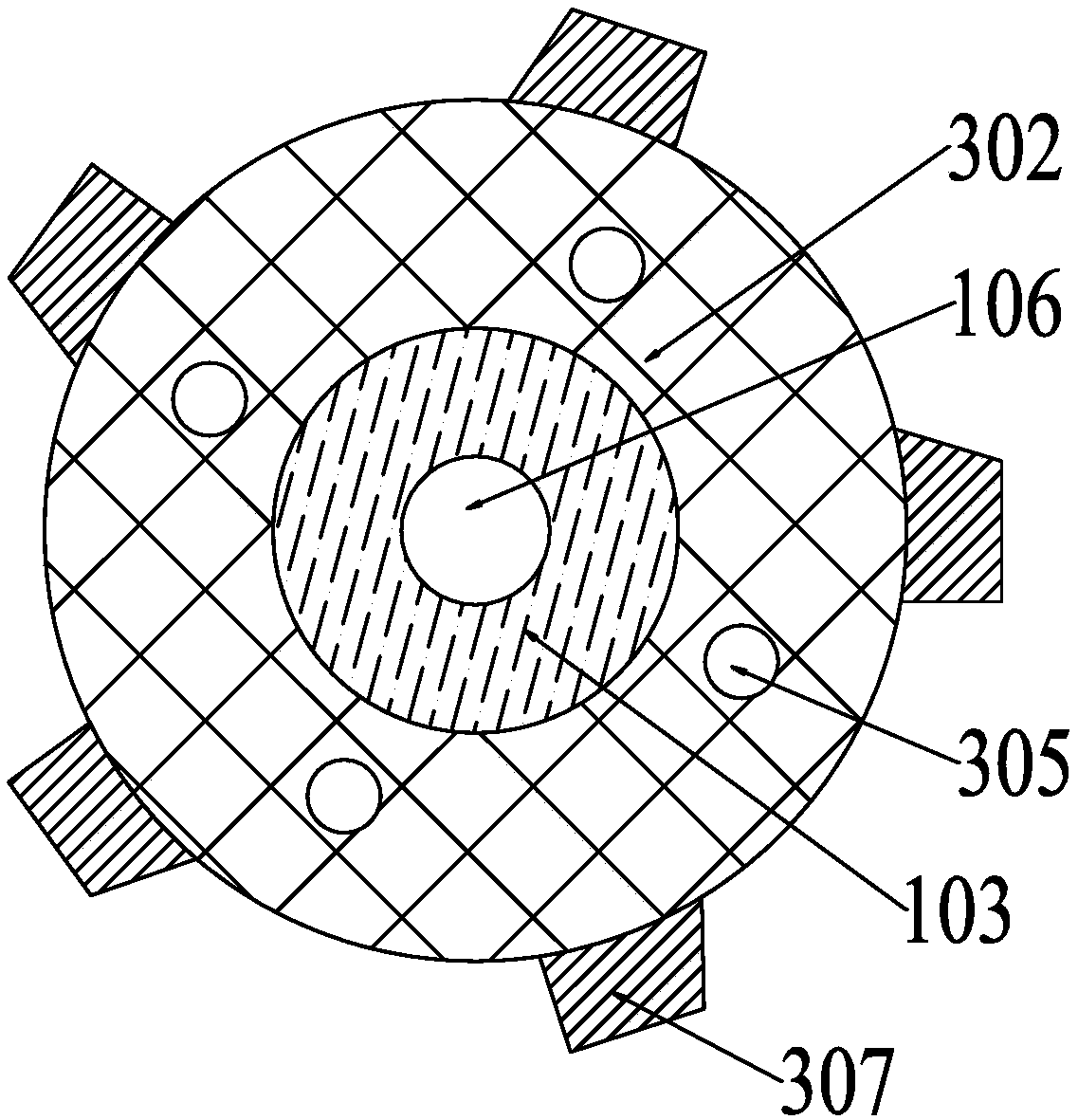

[0036] Embodiment one: see figure 1 , figure 2 , Figure 4 , provides an adaptive torque balance differential pressure drill bit, including a conversion joint 2, a reaming drill bit 3 and a pilot drill bit 4, and also includes a torque transmission device 1 for transmitting torque, the conversion joint 2, the torque The transmission device 1 is integrated with the pilot drill bit 4, the reaming drill bit 3 is located between the conversion joint 2 and the pilot drill bit 4, and is installed on the outside of the torque transmission device 1; the torque transmission The device 1 includes a first transmission member 101, a rotating member 102 and a second transmission member 103 which are sequentially connected as one, the first transmission member 101 is connected to the conversion joint 2, the second transmission member 103 is connected to the collar The rotating part 102 is provided with at least one stopper 104, and the torque transmission device 1 also includes a stopper...

Embodiment 2

[0053] Embodiment two: see Figure 6 , provides an adaptive torque balance differential pressure drill bit, different from the first embodiment above, in this embodiment, the adaptive torque balance differential pressure drill bit not only includes the torque transmission device described in the above embodiment 1. The conversion joint 2, the reaming bit 3, the pilot bit 4 and the first elastic member 6, also include the drill pressure used for transmitting the reaming bit 3 to break the rock, and distributing the reaming bit 3 and the pilot bit 4. The second elastic member 7 that accounts for the weight-on-bit ratio, and the second elastic member 7 is placed in the space formed after the reaming bit crown 302, the rotating member 102 and the second transmission member 103 are installed and matched . The torque transmission device 1 is connected to the conversion joint 2 on the top, the pilot drill 4 on the bottom, and the reaming drill 3 is installed in the middle. Its funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com