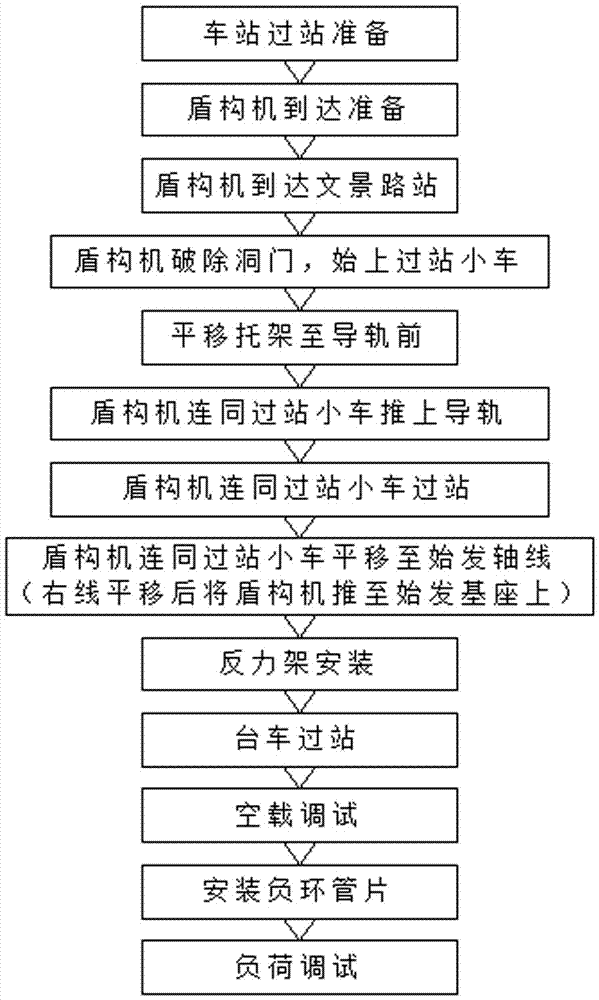

Construction method of shield machine rapid station passing in small space

A construction method and technology of shield machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

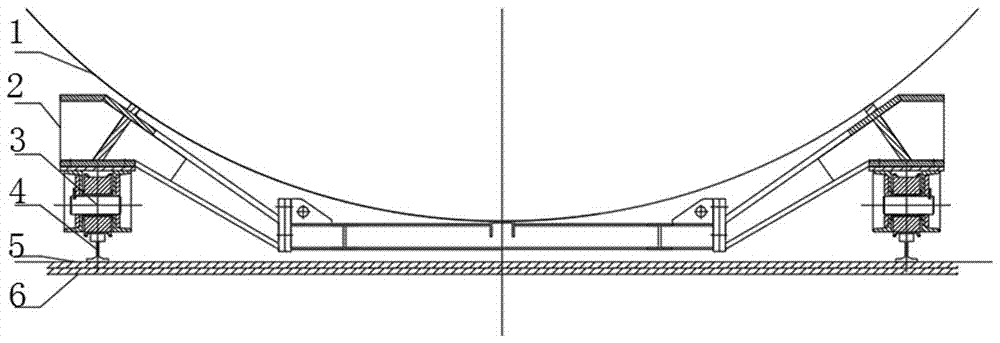

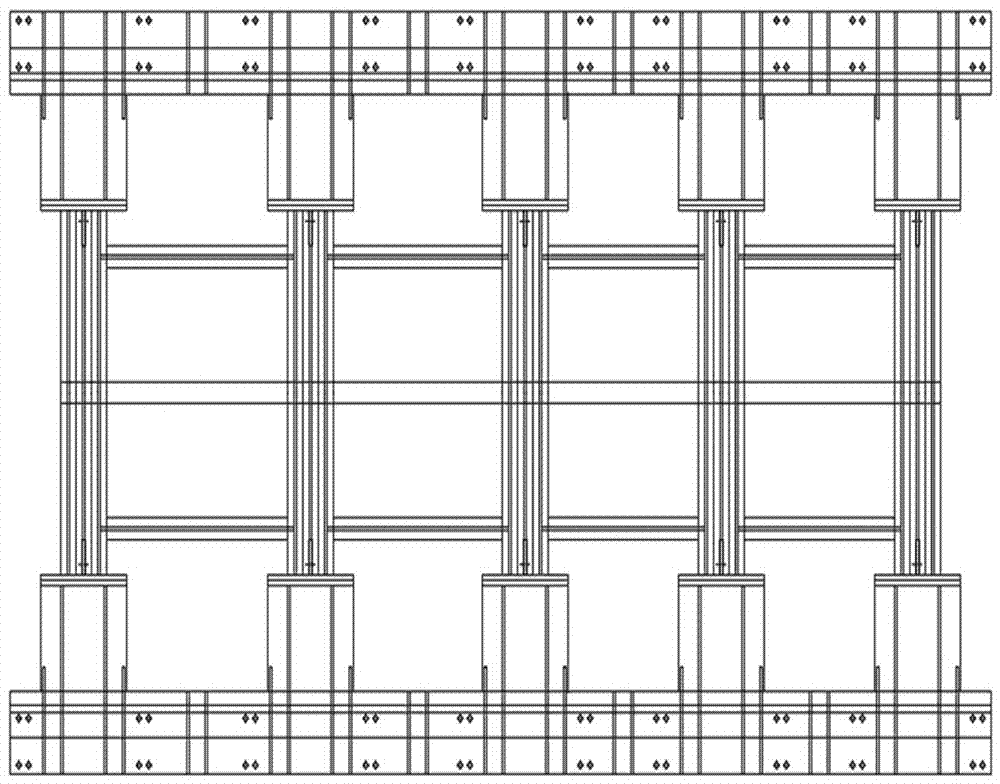

[0047] Generally, the length of the receiving shaft of the shield machine in most subway construction stations is about 12 meters, with a net height of 7-8 meters and a net width of about 10 meters. The standard section of the station is about 120-200 meters long and 7 meters high and 7 meters wide. As long as the space design size can satisfy the passing capacity of the shield machine, the station passing trolley 2 can be used to pass the station. Taking the 15th mark of Xi'an Metro Line 4 as an example, the following is an introduction to the construction method of the shield machine using the station-passing trolley 2 to quickly pass through the station.

[0048] Scope of application: mainly for the subway stations that have been capped and the stations that have not reserved crane exits, the station passing trolley 2 is used to carry out the shield machine passing construction. The construction site has been capped, and the internal structure is narrow enough for the shie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com