An engine fuel supply support plate casing structure and an engine comprising the structure

An engine and trigger technology, applied in the direction of engine lubrication, engine function, engine components, etc., can solve problems such as large aerodynamic loss, flow field disturbance, engine resonance, etc., to improve operation safety, reduce aerodynamic excitation force, Avoid the effects of higher order resonances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

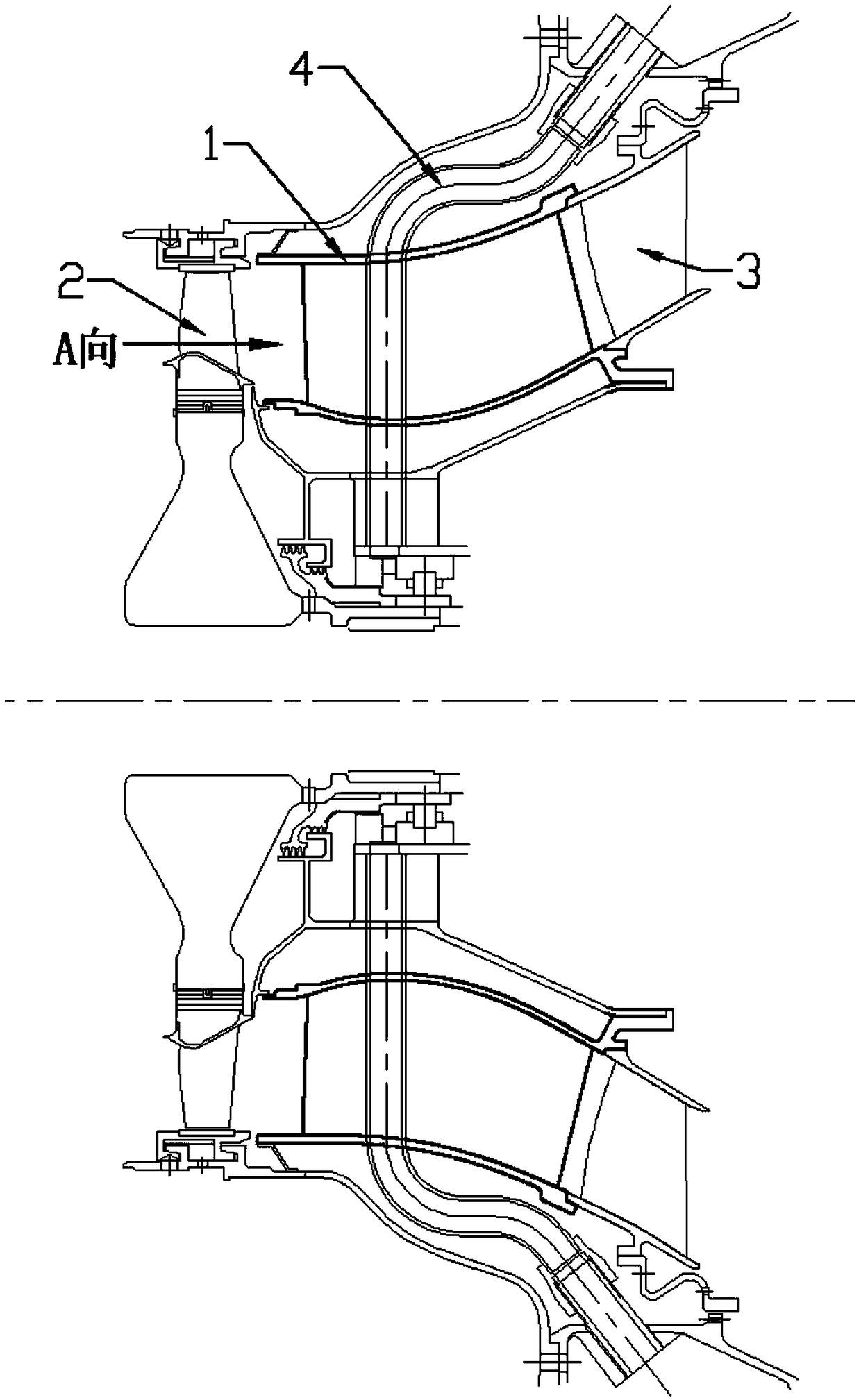

[0024] figure 1 It is a schematic diagram of assembly of the casing structure of the engine oil supply support plate of the present invention in the engine. 1 is the oil supply support plate casing, 2 is the high-pressure turbine rotor, 3 is the low-pressure turbine guide, and 4 is the lubricating oil pipeline. Among them, the high-pressure turbine rotor 1 is located upstream, the low-pressure turbine guide 3 is located downstream, and the oil supply support plate casing 1 is located in the transition section between the high-pressure turbine rotor 2 and the low-pressure turbine guide 3, and is welded to the low-pressure turbine The guides 3 are fixedly connected together. In order to ensure the welding effect, achieve a good supporting effect and pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com