Blade optical rapid measurement method based on double-probe four-axis measurement system

A measurement system and measurement method technology, applied in measurement devices, optical devices, instruments, etc., can solve problems such as difficulty in satisfying multi-angle and omni-directional three-dimensional scanning, inability to measure, etc., to solve the lack of point cloud data and improve measurement accuracy. , Measuring the effect of process automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention or invention are described in further detail below in conjunction with accompanying drawing:

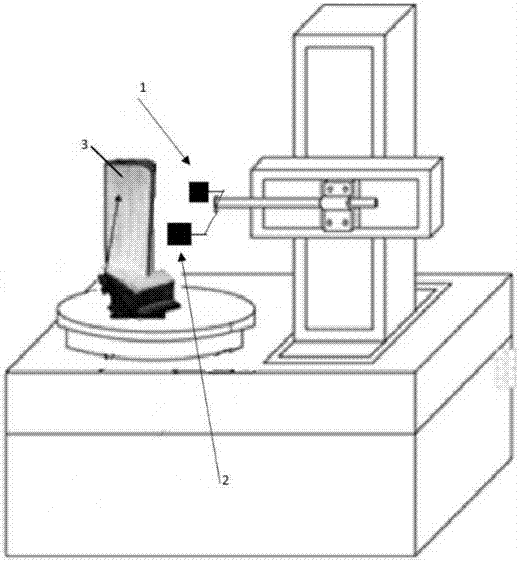

[0019] see figure 1 , a blade shape fast scanning method specifically includes the following steps:

[0020] In the first step, the initial model of the blade is used to calculate the surface point normal vector.

[0021] 1) Use the initial design model of the blade to sample points to obtain the point cloud data of the initial design model.

[0022] 2) Using the least squares plane fitting algorithm, the direction of the normal vector is calculated point by point for the above sampling points.

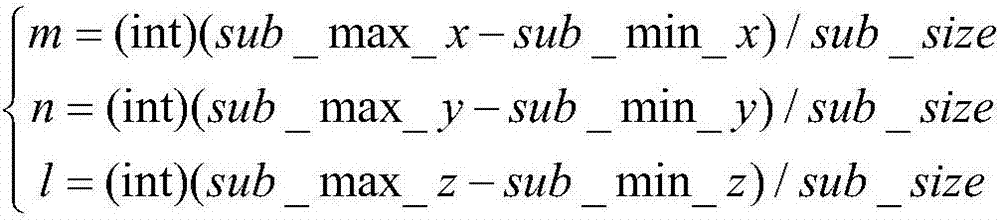

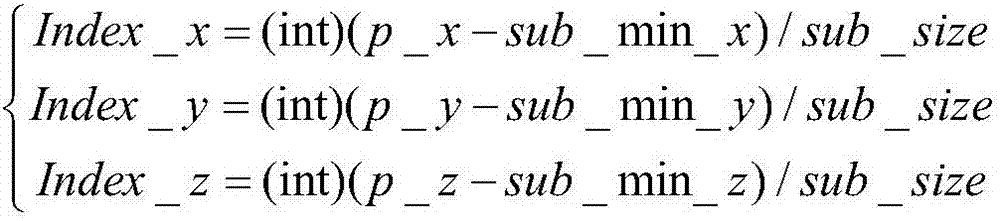

[0023] (1) First calculate each measuring point x i The K-nearest neighbors. At present, the common K-nearest neighbor calculation methods include spatial cell method, octree method and K-d tree method. In the present invention, the spatial cell method is adopted. Its algorithm principle is as follows.

[0024] let p = {p 1 ,p 2 ,...,p n} is a set of sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com