Preparation method of crop straw feed

A crop straw and feed technology, which is applied in the field of crop straw feed preparation, can solve problems such as difficulty in satisfying modern agriculture and animal husbandry, and inability to improve the comprehensive efficiency of straw feeding, and achieve high-pressure air tightness, energy saving, and ecological cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

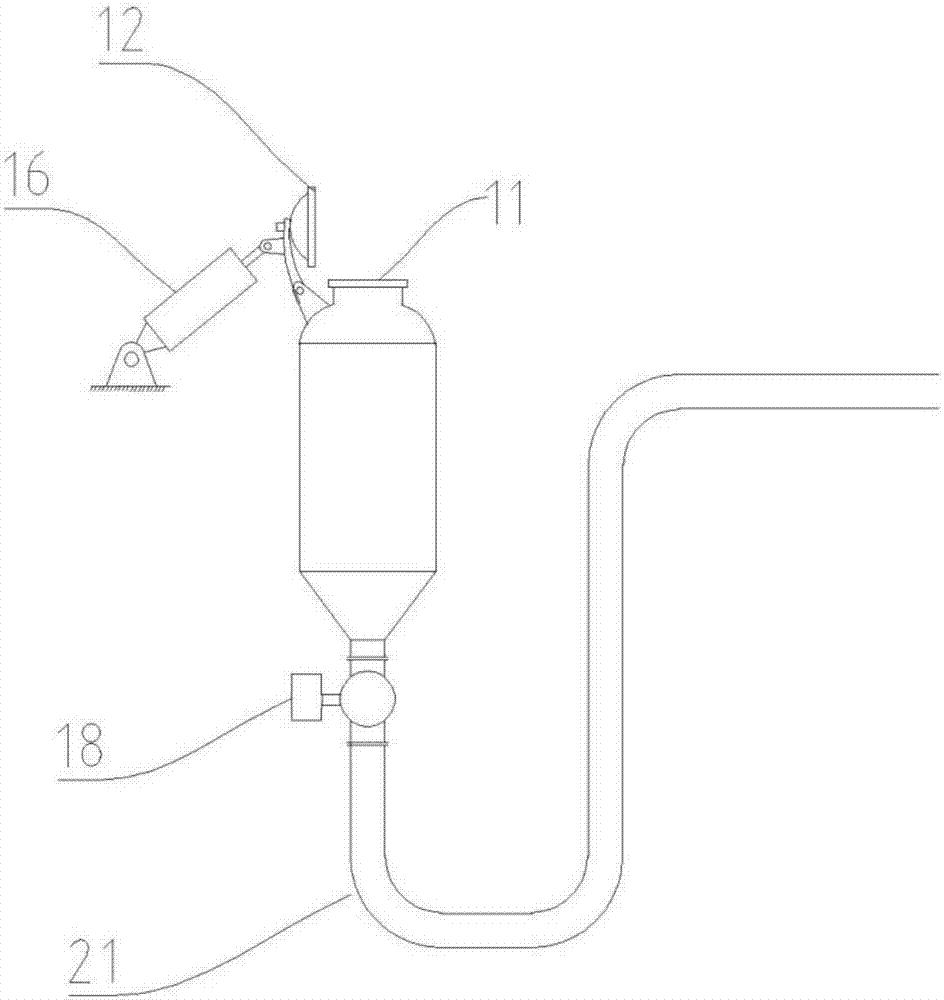

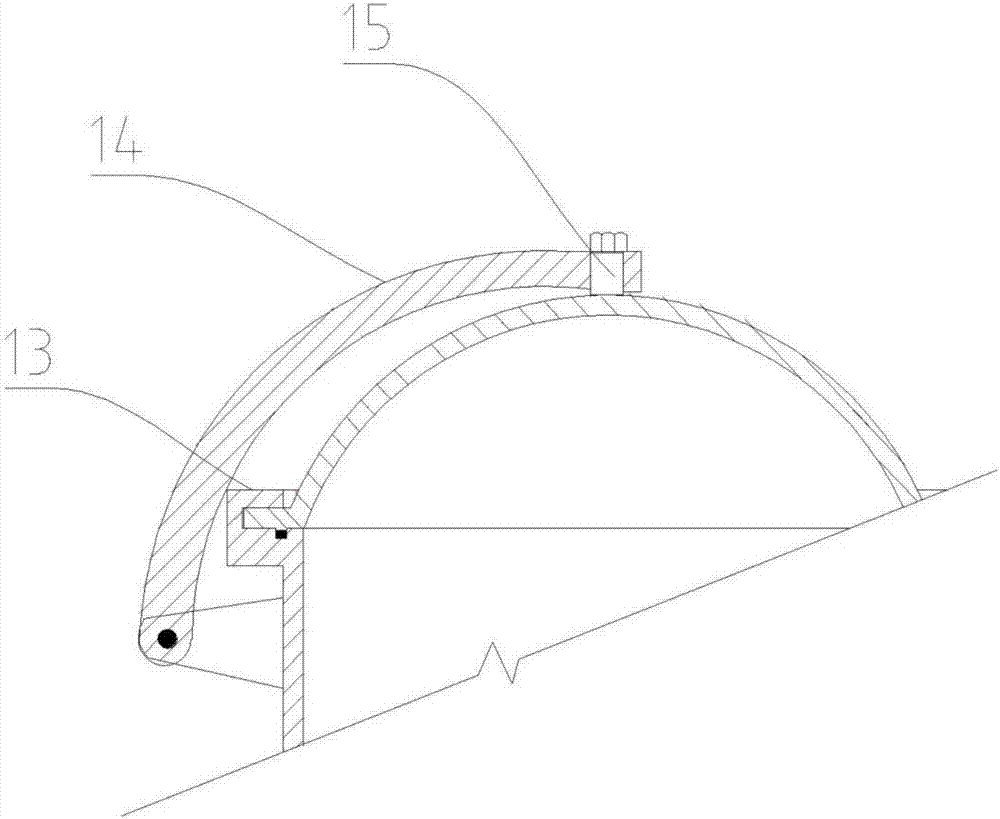

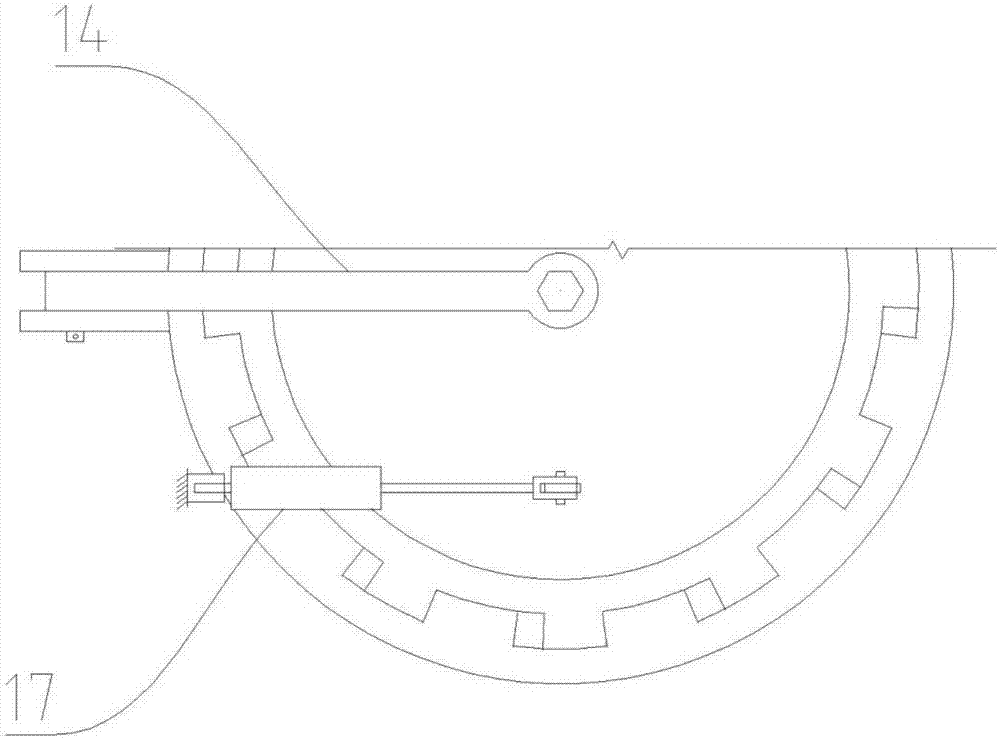

[0033] The preparation method of a kind of crop stalk feed of the present invention comprises the following steps: step 1, cuts the crop stalk to 3cm, puts into the pressure-resistant reactor, such as Figure 1-4 As shown, the pressure-resistant reactor has a discharge port, the discharge port is provided with a discharge valve 18, and the discharge port is communicated with the friction pipe 21, and the inner wall of the friction pipe 21 is evenly ringed with a plurality of Sharp protrusions 22, wherein the discharge valve 18 is closed before the crop stalks are put into the pressure-resistant reactor;

[0034] Wherein, the moisture content of the crop straw is 12%, which is a mixture of corn straw, wheat straw, rice straw, cotton straw, soybean straw, sesame stalk, sunflower stalk and rape straw.

[0035] Step 2: Introduce saturated water vapor into the pressure-resistant reactor, and carry out two high-temperature and high-pressure reactions in succession, among which, pres...

Embodiment 2

[0044] A method for preparing crop straw feed of the present invention comprises the following steps: step 1, cutting the crop straw to 7 cm, and putting it into a pressure-resistant reaction kettle, such as Figure 1-4 As shown, the pressure-resistant reactor has a discharge port, the discharge port is provided with a discharge valve 18, and the discharge port is communicated with the friction pipe 21, and the inner wall of the friction pipe 21 is evenly ringed with a plurality of Sharp protrusions 22, wherein the discharge valve 18 is closed before the crop stalks are put into the pressure-resistant reactor;

[0045] Among them, the moisture content of the crop straw is 38%, which is a mixture of corn straw, wheat straw, rice straw, cotton straw, soybean straw, sesame stalk, sunflower stalk and rapeseed straw.

[0046] Step 2. Pass saturated water vapor into the pressure-resistant reactor, and carry out two consecutive high-temperature and high-pressure reactions. Among them...

Embodiment 3

[0055] A method for preparing crop straw feed of the present invention comprises the following steps: step 1, cutting the crop straw to 10 cm, and putting it into a pressure-resistant reaction kettle, such as Figure 1-4 As shown, the pressure-resistant reactor has a discharge port, the discharge port is provided with a discharge valve 18, and the discharge port is communicated with the friction pipe 21, and the inner wall of the friction pipe 21 is evenly ringed with a plurality of Sharp protrusions 22, wherein the discharge valve 18 is closed before the crop stalks are put into the pressure-resistant reactor;

[0056] Wherein, the moisture content of the crop straw is 75%, which is a mixture of corn straw, wheat straw, rice straw, cotton straw, soybean straw, sesame stalk, sunflower stalk and rape straw.

[0057] Step 2: Introduce saturated water vapor into the pressure-resistant reactor, and carry out two consecutive high-temperature and high-pressure reactions, among which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com