Kitchen waste separation treatment system

A kitchen waste, separation and treatment technology, applied in the field of kitchen waste separation and treatment systems, can solve the problems of unsuitable treatment, insufficient combustion of incinerators, immature technology, etc., to reduce the difficulty and cost of treatment, improve the surrounding water ecology, The effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

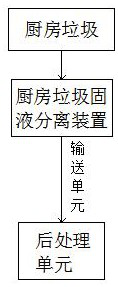

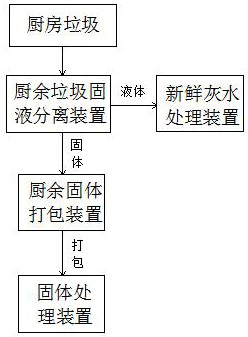

[0030] see figure 1 , the present invention provides a kitchen waste separation and treatment system, which is sequentially composed of a kitchen waste solid-liquid separation device, a conveying unit and a post-processing unit; wherein, the kitchen waste solid-liquid separation device is used to separate the solid-liquid The liquid is separated; the conveying unit is used to collect and transport the solid and liquid separated by the kitchen waste solid-liquid separation device to the post-processing unit; the post-processing unit is to collect and transport the received solid-liquid Hazardous treatment, resource treatment.

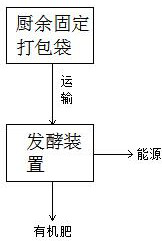

[0031] Specifically, such as figure 2 As shown, it also includes a food waste solid packaging device, which is located at the end of the kitchen waste solid-liquid separation device, and uses a packaging film to independently package food waste solids, cut them off, and then transport them.

[0032] During implementation, the installation film is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com