Spanner used for rotating gear and motor rotor rotating method

A technology for turning gears and wrenches, which is applied in the direction of wrenches, manufacturing stator/rotor bodies, and manufacturing tools. Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Through observation, it is found that the gear shaft press-fitted on the extension side of the motor shaft generally has a middle through hole (center hole), which is required for the manufacturing and assembly process. The center line of the gear shaft is the center line of the rotor rotation, the teeth on the outer edge of the gear shaft can play a meshing role, and the center distance is designed to be adjustable.

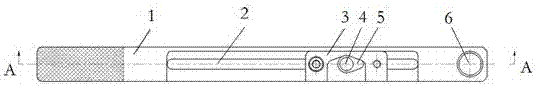

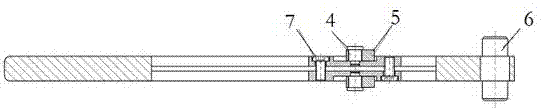

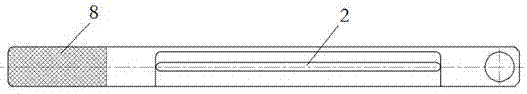

[0033] Please refer to Figure 1 to Figure 9 , A wrench 11 for rotating gears includes a main body 1, a movable block 3, a positioning pin 4, a movable tooth 5, a positioning pin 2 6, and a hexagon socket head cap screw 7. One end of the main body is set as a handle 8, and the two positioning pins are fixedly connected to the other end of the main body. The middle section of the main body is provided with a strip-shaped through hole 2 (movable slots can also be set on the front and back of the main body along the length direction of the main body, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com