Practical septic tank

A technology of septic tanks and septic tanks, which is applied in the direction of biological sludge treatment, etc., can solve the problems of complex process, passive, difficult to suck clean, etc., and achieve the effect of simple structure and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

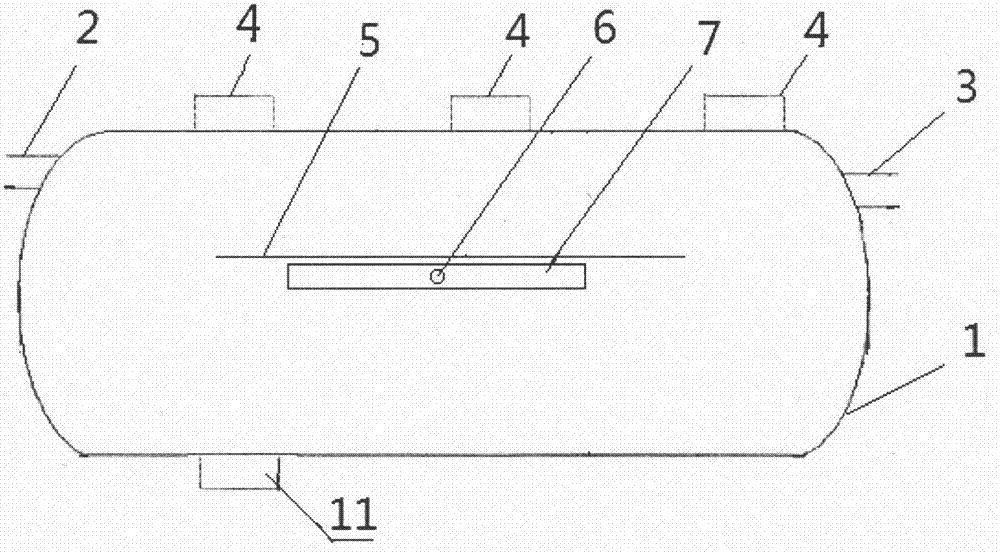

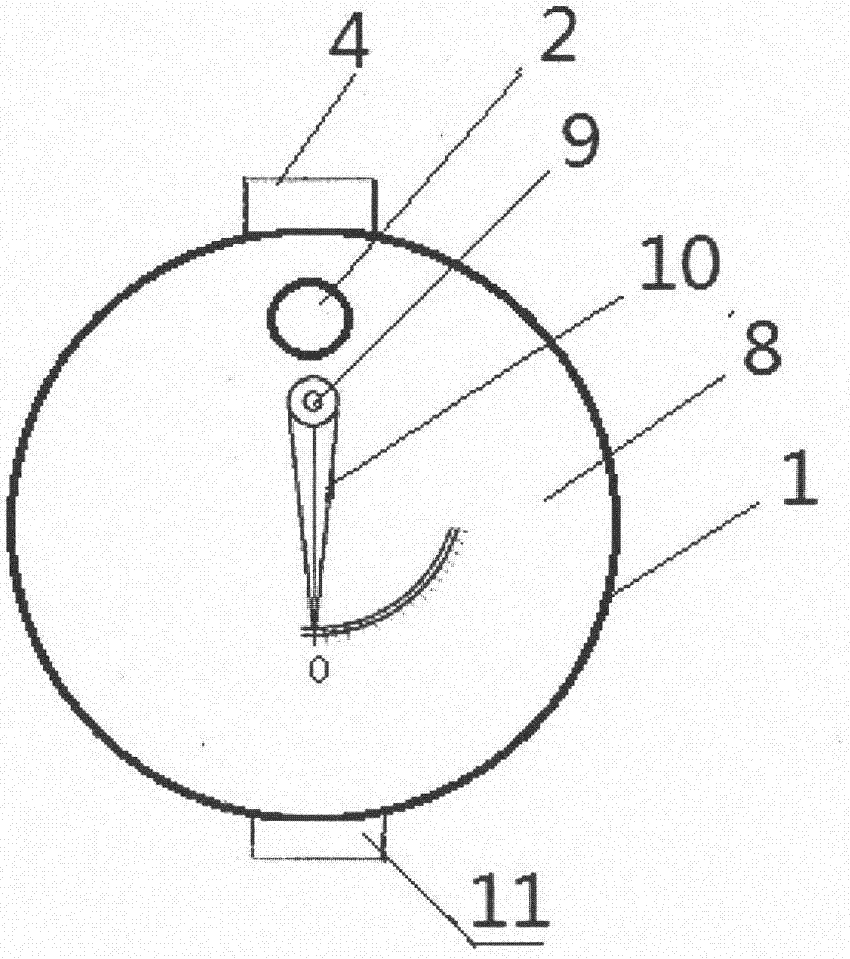

[0008] figure 1 , figure 2 Among them, it consists of cylinder body (1), water inlet pipe (2), water outlet pipe (3), clearing hole (4), parallel line (5), mounting column (6), lever ruler (7), end face (8 ), the installation column (9), the vertical needle (10) and the clearing well (11) are formed, wherein, it is provided with the clearing well ( 11); a parallel line (5) parallel to the top surface of the cylinder (1) is provided on the septic tank, and a lever ruler (7) is movable linked on the mounting column (6) of the cylinder (1); Vertical needles (10) are movably connected to the installation column (9) provided on the end surface (8) of the pool cylinder (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com