Heat-insulation water-control degradable mulch preparation method

A technology for degrading mulch and heat preservation, applied in botany equipment and methods, plant protection, plant protection covers, etc., can solve the problems of low degradation rate and untargeted production and preparation methods, achieve high degradation rate and improve overall mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

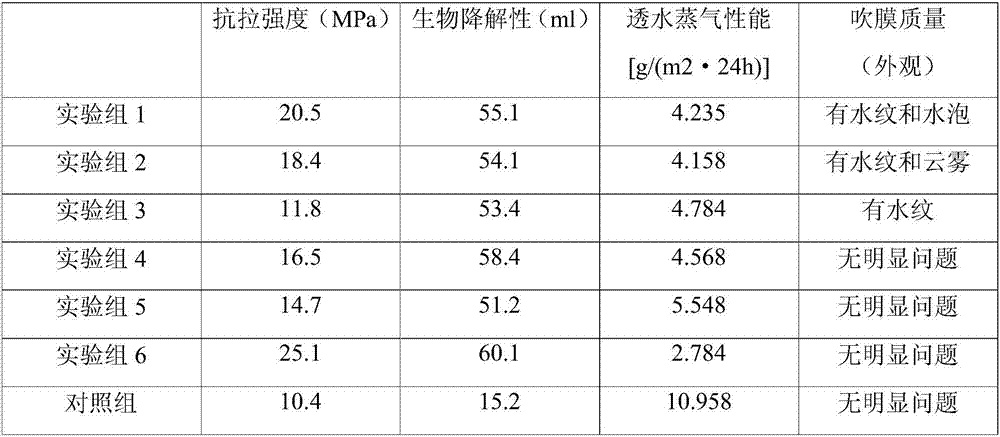

Image

Examples

Embodiment

[0028] This embodiment discloses a method for preparing a degradable film for heat preservation and water control, the steps of which include:

[0029] 1. Selection of raw materials and pretreatment

[0030] First select raw materials according to mass fraction:

[0031] Polylactic acid 20%-40%;

[0032] Polycarbonate 25-30%;

[0033] Polyethylene adipate 20-35%;

[0034] Grafted compatibilizer 15-18%.

[0035] All raw materials are dried first to avoid poor quality of subsequent granulation caused by excessive moisture. Then put the dried polylactic acid and polycarbonate into vacuum drying equipment respectively, and carry out secondary baking at 76° C. for 17 hours, in order to improve the compatibility during subsequent melt copolymerization.

[0036] 2. Stir and mix the raw materials

[0037] Then the baked polylactic acid is taken out, and the prepared polyethylene adipate, grafted compatibilizer and polylactic acid are mixed, put into a high-speed mixer and stirre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com