Adhesive for high-speed rail and preparation method of adhesive

A technology of adhesive glue and high-speed rail, applied in the direction of non-polymer adhesive additives, wax adhesives, adhesive types, etc., can solve problems such as waste, waste of manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] Another aspect of the present invention provides the preparation method of described adhesive glue for high-speed rail, comprising the following steps:

[0070] (1) Add corresponding parts by weight of polyurethane prepolymer, epoxy resin prepolymer and 2-diethylaminoethanol into a stainless steel reactor, and heat up to 120-150°C, then stir and react for 2-5 hours to obtain a gel-like product;

[0071] (2) Add silane coupling agent modified sulfonated polybenzimidazole, diluent, and white oil to the gel-like product obtained in step (1) and stir for 1 to 2 hours at 150°C; cool to room temperature, and discharge Obtain adhesive glue for high-speed rail.

Embodiment 1

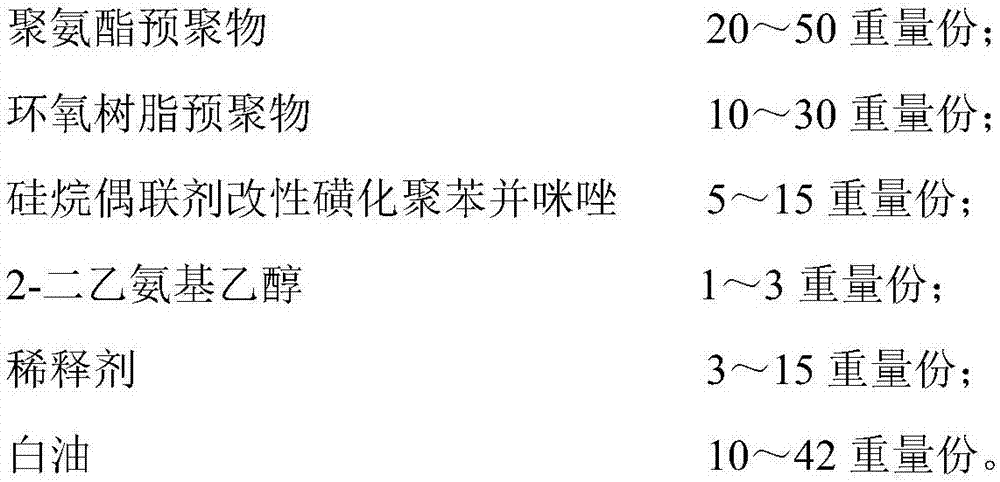

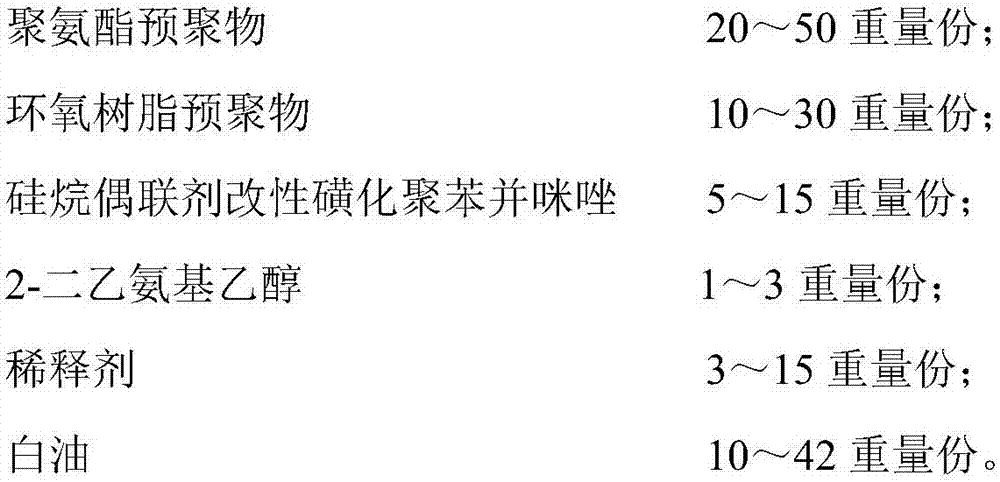

[0075] Embodiment 1 provides a kind of adhesive glue for high-speed rail, and described adhesive glue for high-speed rail comprises the following components, in parts by weight,

[0076]

[0077] The preparation process of the polyurethane prepolymer is as follows :

[0078] In a dry three-necked flask, add 5 moles of glycerin, vacuum dehydrate at 110°C for 0.5h, cool down to 60°C, add 1 mole of xylene, then add 3 moles of hydroxypyridine modified tetraisocyanate, and heat up to 80°C , reacted for 3h, cooled to room temperature, filtered and dried to obtain polyurethane prepolymer;

[0079] Among them, the molar ratio between glycerol and hydroxypyridine-modified tetraisocyanate is 5:3.

[0080] The preparation process of described hydroxypyridine modified tetraisocyanate is as follows:

[0081] 3 moles of 5-hydroxyl-2-pyridinecarboxylic acid and 3 moles of dimethyltriphenylmethane tetraisocyanate were dissolved in 100ml of dimethyl sulfoxide respectively to obtain 5-...

Embodiment 2

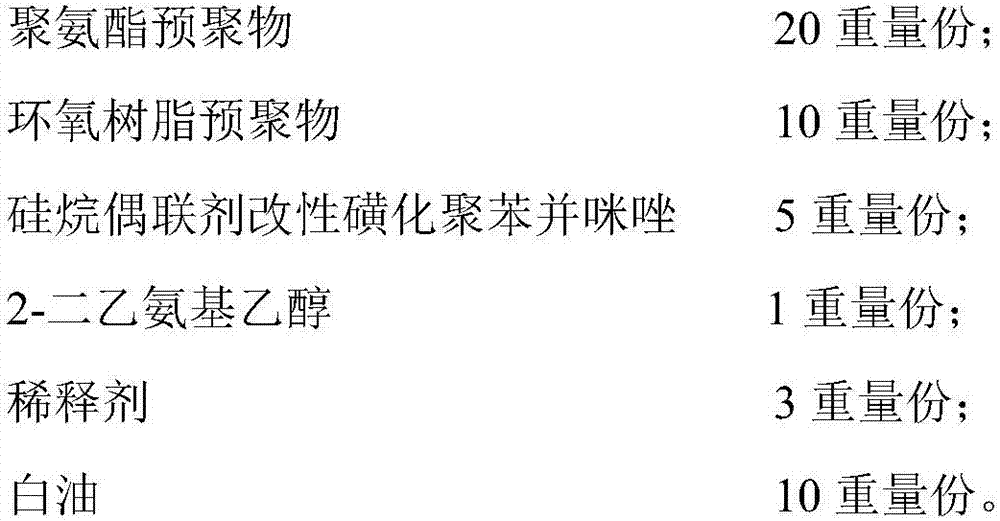

[0093] Embodiment 2 provides a kind of adhesive glue for high-speed rail, and described adhesive glue for high-speed rail comprises the following components, in parts by weight,

[0094]

[0095] The preparation process of the polyurethane prepolymer is as follows :

[0096] In a dry three-necked flask, add 5 moles of glycerin, vacuum dehydrate at 110°C for 0.5h, cool down to 60°C, add 1 mole of xylene, then add 3 moles of hydroxypyridine modified tetraisocyanate, and heat up to 80°C , reacted for 3h, cooled to room temperature, filtered and dried to obtain polyurethane prepolymer;

[0097] Among them, the molar ratio between glycerol and hydroxypyridine-modified tetraisocyanate is 5:3.

[0098] The preparation process of described hydroxypyridine modified tetraisocyanate is as follows:

[0099] 3 moles of 5-hydroxyl-2-pyridinecarboxylic acid and 3 moles of dimethyltriphenylmethane tetraisocyanate were dissolved in 100ml of dimethyl sulfoxide respectively to obtain 5-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com